Industry automation

Let's streamline the future together!

As the main contractor, we provide complex services for the implementation of a smart factory with the principles of Industry 4.0 from design, sensor technology, PLC, SCADA, MES system, to interconnection with the ERP system.

We can advise you on the collection of relevant online data, and vertical and horizontal communication across the company. Be an example of production automation for others.

Our goal is to find a suitable solution with the aim of higher production efficiency with a short return on investment.

EPR

H-level+: customized connection with ERP / MES / IT systems based on OPC-UA, MQTT, TCP-IP, Modbus TCP

MES

MES+: modular system for smart factories and online collection of relevant data, production monitoring, production planning and control, maintenance management, quality management and traceability, production visualization, performance analysis

SCADA network

SCADA+: control rooms for complex lines, the application can visualize data from all sensors and actuators on the line

Mobility+: Remote control panel or industrial tablet for maintenance, service, local control, client visualization application, mirror image of control room application

client visualization application, mirror image of the velin application

Digital Twin+: a virtual model designed to accurately reflect a physical object. Updated from real-time data, uses simulation, machine learning and reasoning to help decision-making

PLC

IoT+: IoT+: secure internet connection, via the customer's network or via a mobile operator will enable remote management and extended package functions (Diagnostics +, Service +, Vibro +)

Servis+: interactive procedures for service activities and maintenance (videos, PDF on HMI panels), display of spare and wear parts, send an email with a request for delivery to the Prestar service center or customer (IoT+ needed).

RFID+: operator logging, component monitoring according to the selected production method

Vibro+: vibro-diagnostics, data collection for predictive maintenance, email notifications

Data+: data archiving locally based on MS SQL

Data Cloud+: data cloud archiving solution

Diagnostics+: interactive diagnostics, in case of a fault it will refer graphically to the place on the line, instructions / procedure how to eliminate the fault

Sensor

Optimization+: test operation after handover of the line with the participation of a programmer with extended operator training and optimization of the production process

Automated special workplaces

Complex design and implementation of automation of workplaces.

Robotic cells

Fully automated robotic cells, including other automated units and fixtures.

Linear positioning axes and systems

Complete solutions for various types of automation of handling processes.

Automated special workplaces

Complex design and implementation of automation of workplaces, technological units, production lines, assembly and test stations.

Robotic cells

Fully automated robotic cells, including other automated units and fixtures, are usually integrated into existing production and perform special-purpose activities such as handling, assembly, welding, measuring, surface treatment, etc.

Linear positioning axes and systems

Complete solutions for various types of automation of handling processes. Standard modules can be combined as a stand-alone component or as an integrated axis system. including peripherals. A wide range of concept variants for mounting an actuator or robotic arm, either in gantry or floor-mounted versions.

Automated special workplaces

Complex design and implementation of automation of workplaces, technological units, production lines, assembly and test stations.

Let's streamline the future together!

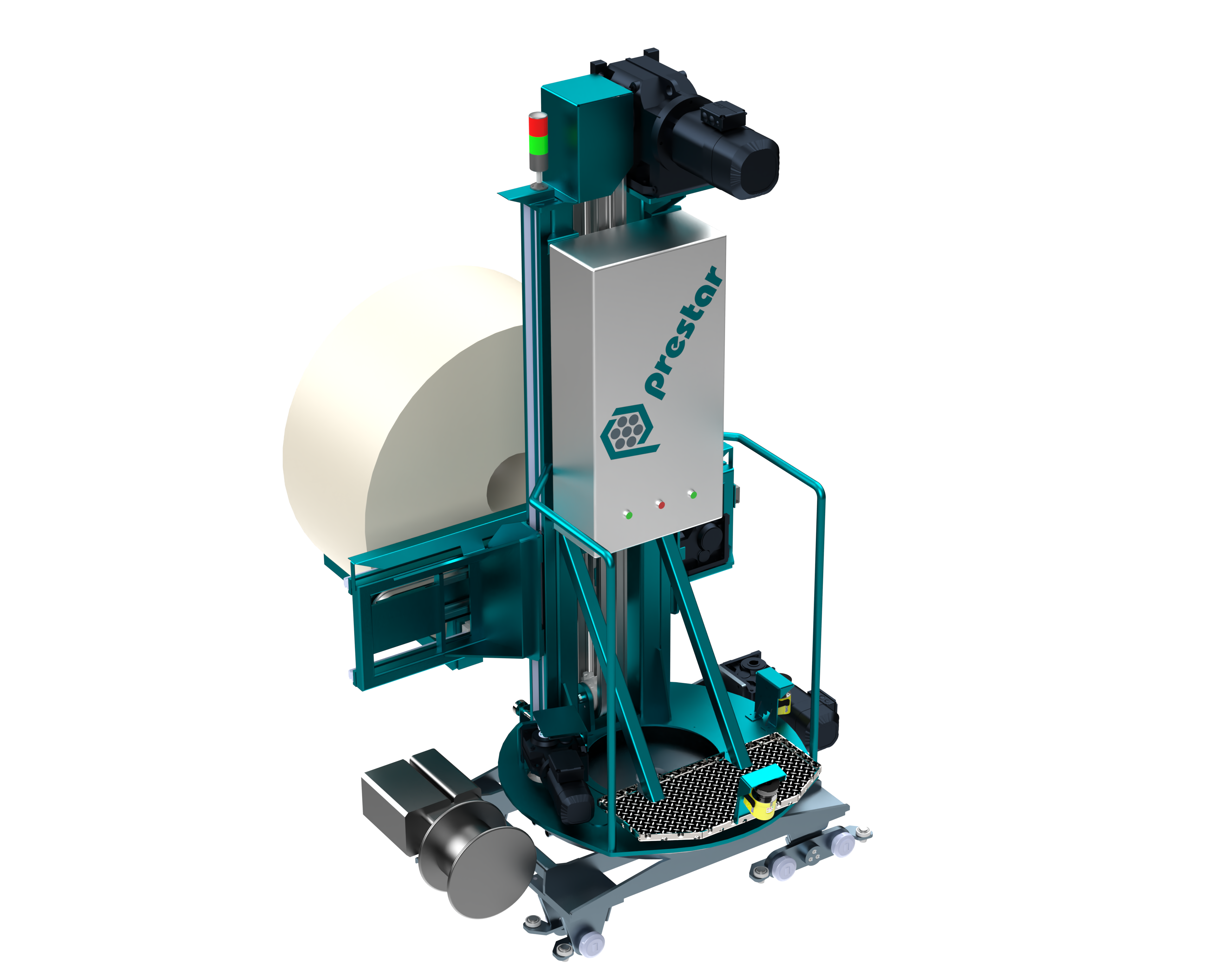

Automatic manipulator for paper rolls

A specific solution for handling paper rolls from the material warehouse to several laminating lines. The solution system consists of chain conveyors and an automatic manipulator to remove the roll from the conveyor and load it into the laminating machine.

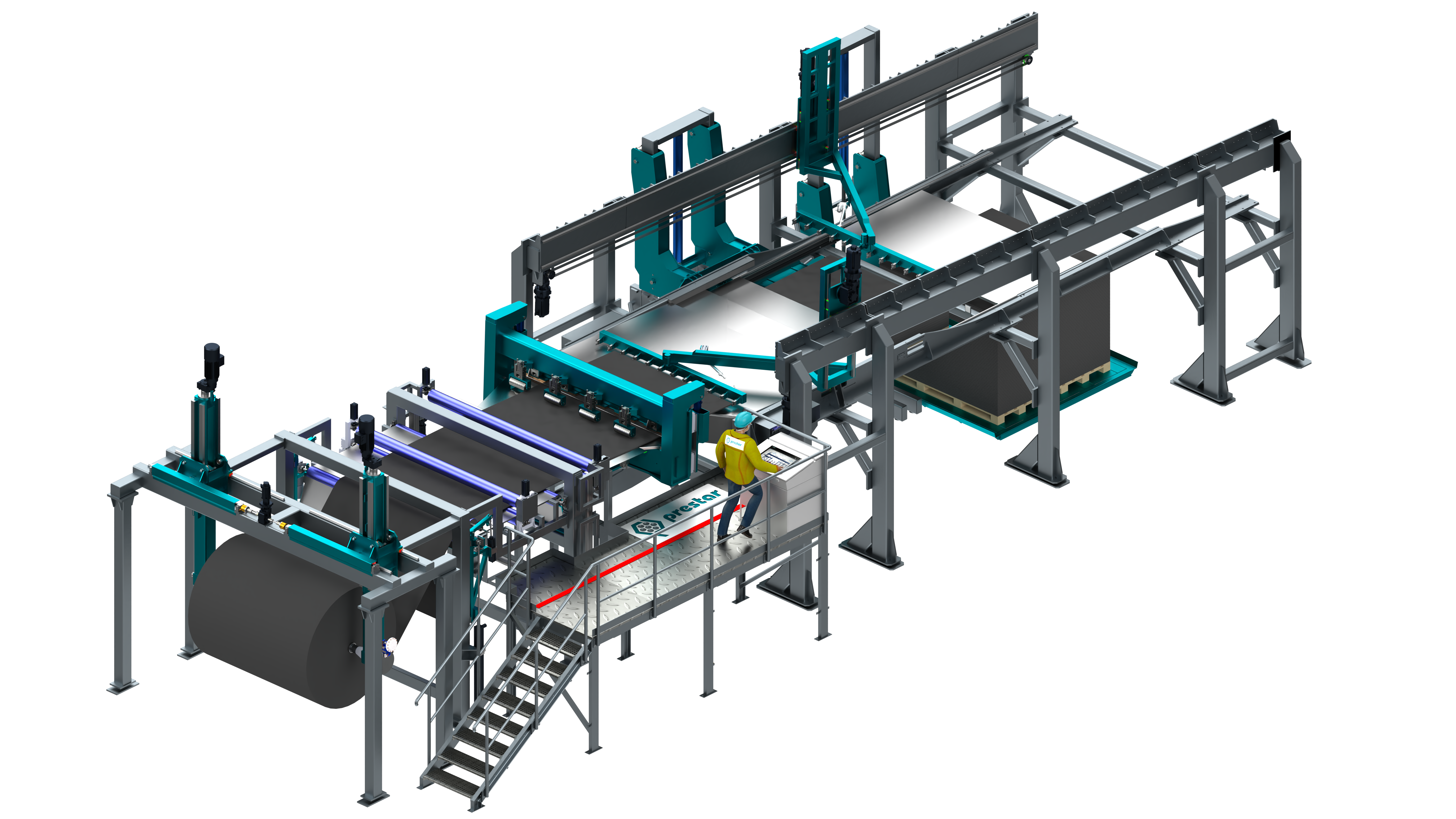

Automatic textile scissors

Equipment for unwinding, cutting and storing fabric. It is designed for cutting textile material from rolls and placing the cuttings on the lifting scissor platform. The device is automatic, after the roll is loaded into the device, the type of roll and the desired length of the cut are selected and the device works automatically.

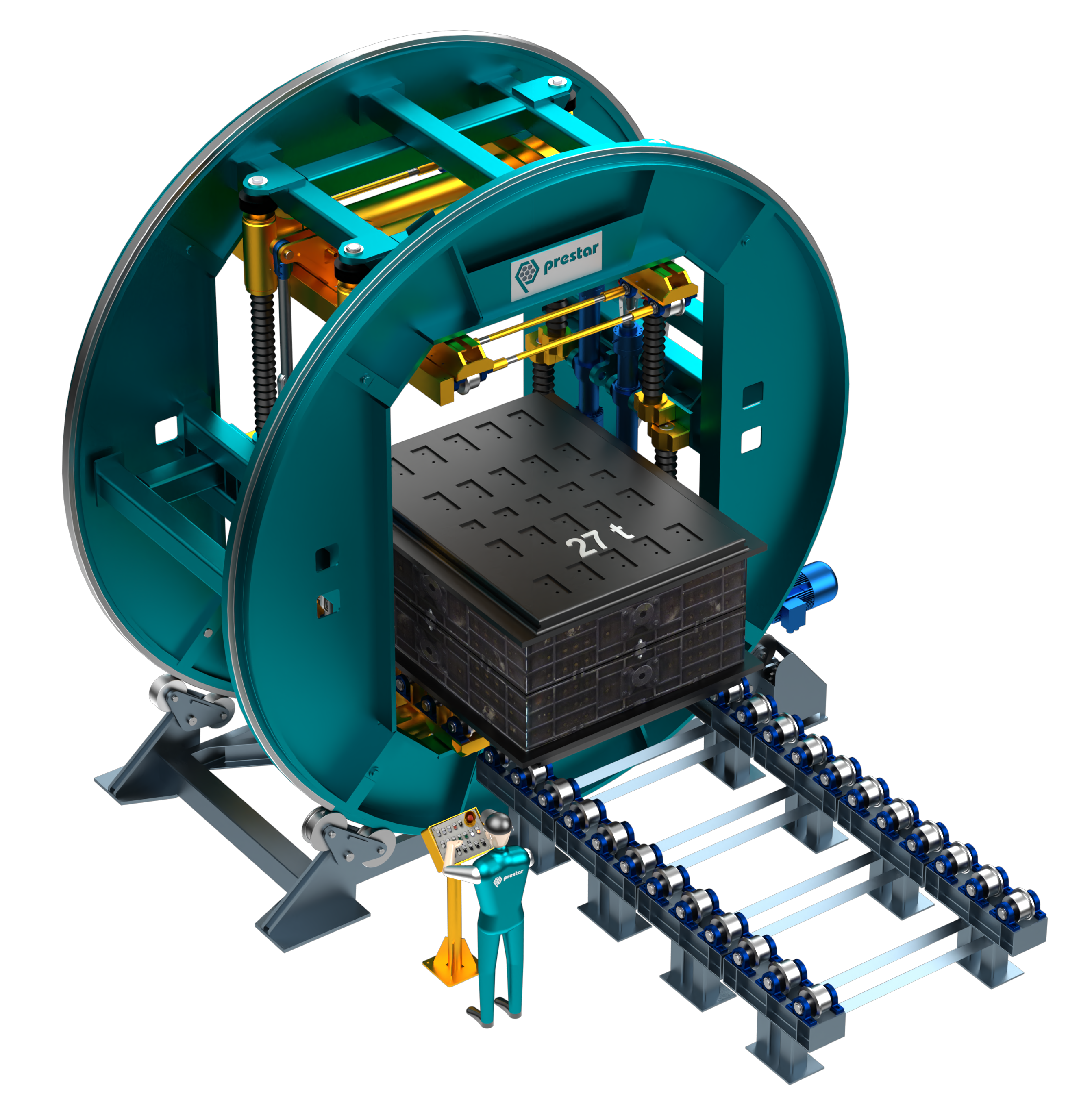

Machine for turning forms

A comprehensive mould handling solution that can meet many different requirements.

Thanks to the advanced hydraulically driven clamping system and electrically designed rotation, the turning station can ensure smooth and precise rotation. The use of engineering quality components results in a device that requires very little maintenance and offers key performance in an industrial environment.

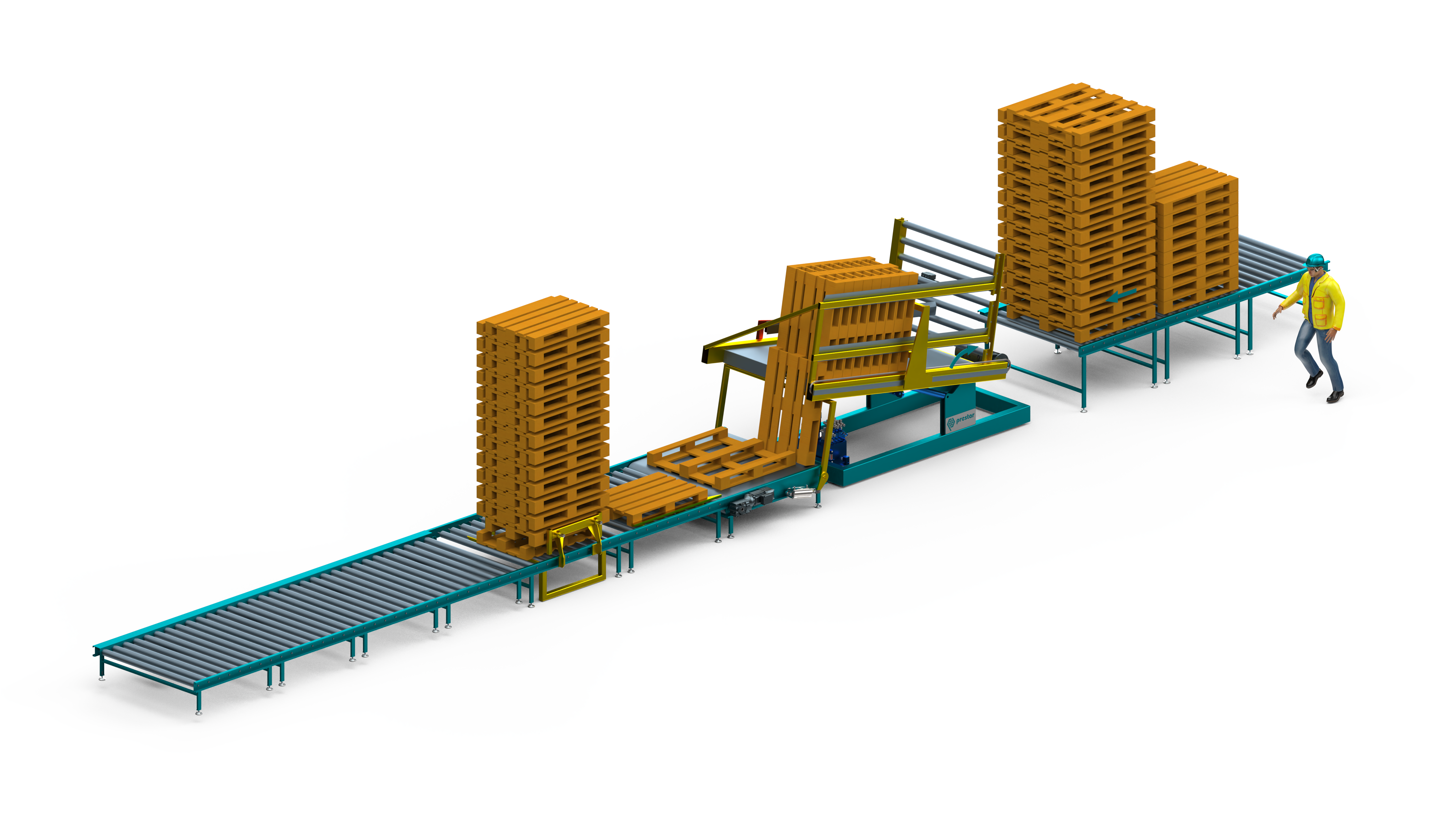

The sorting system for EUR pallets

The pallet sorting system is quick and easy, breaking down pallets one by one and ensuring that pallets can be sorted into quality or type after a short check by the operator.

The machine can process up to 22 stacks of 18 pallets per hour which means that the pallet sorter can handle 400 pallets per hour. In practice, they reach 300 to 350 pallets per hour because the operator also removes plastic, paper and small defects from the pallets during the inspection.

Automation of pallet sorting can demonstrably reduce costs by up to 60%

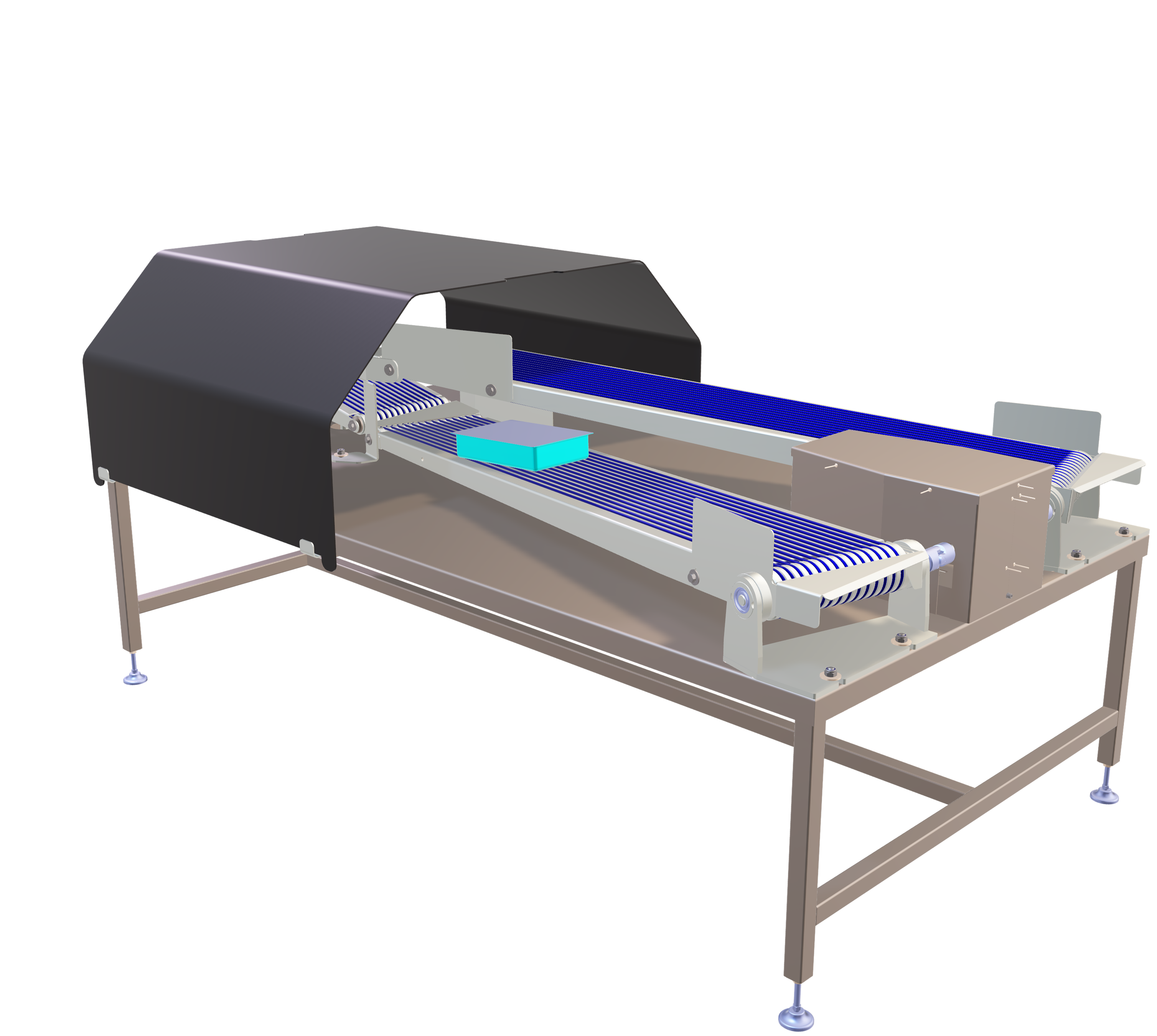

Conveyor for the food industry

A device for transporting packages of packaged meat products, which is capable of dividing the packages from one conveyor into one or the other direction according to a selected number of pieces. The conveyor operates in direct communication with the robotic workstation, which sends signals to the conveyor to flip to the second position.

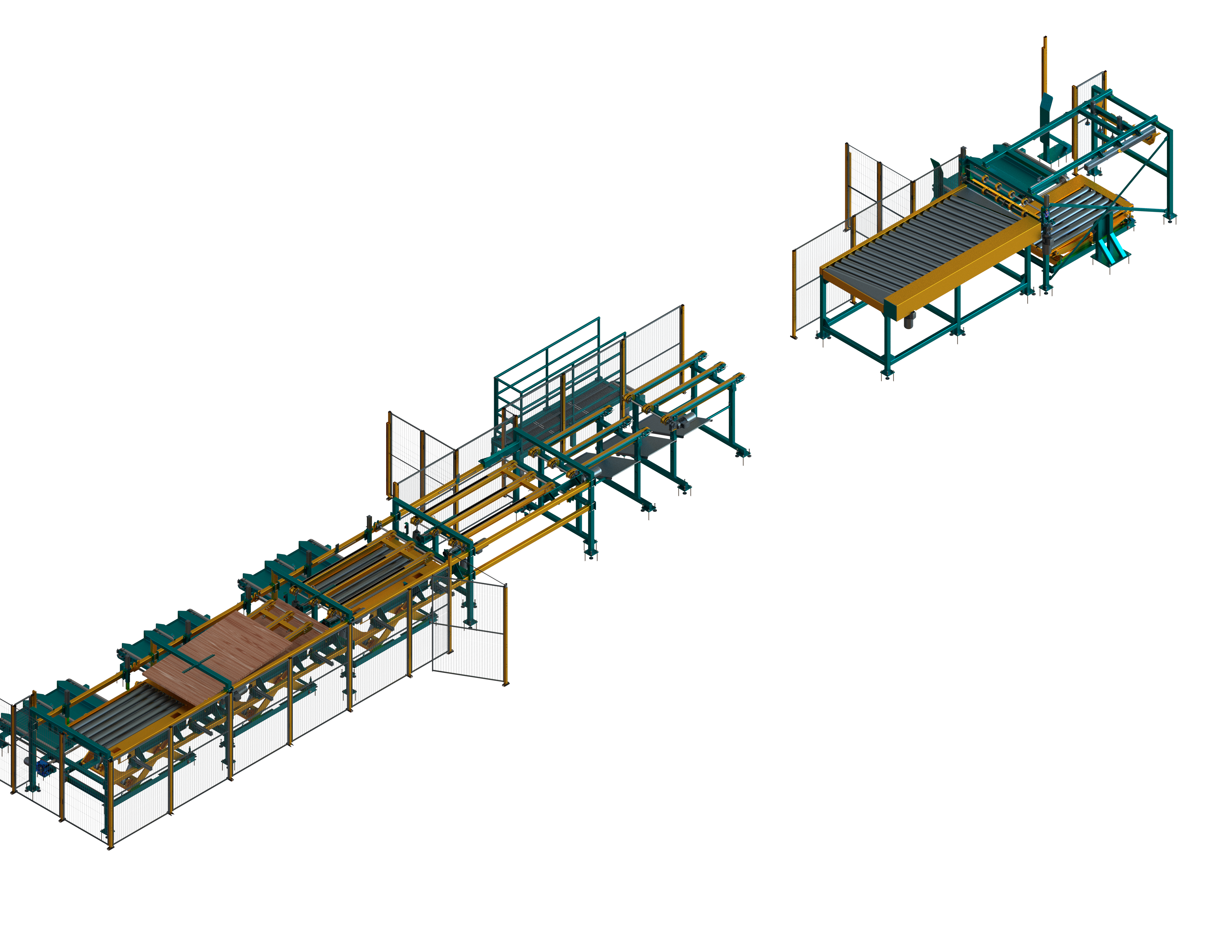

Conveyor of wooden boards to the grinder

Line Served to handle plywood boards, both in stacks and individually. At the beginning of the line Insert a stack of plywood boards and the line feeds them into a grinding machine, which grinds the boards on both sides according to the required qualities surfaces. After grinding, the line also ensures stacking of plates according to quality and export of the full stack for storage or further operations.

Robotic cells

Fully automated robotic cells, including other automated units and fixtures, are usually integrated into existing production and perform special-purpose activities such as handling, assembly, welding, measuring, surface treatment, etc.

Let's streamline the future together!

Robotic workstation for assembling telescopic legs

Robotic workstation for handling profiles stored on pallets to the measuring station and subsequent storage in the assembly cabinet. The equipment includes labeling profiles labelingm and measurements internal and external profile.

Robotic workstation for shield polishing

The basis of the workplace is 6 axial robot, which is suspended from the cabin ceiling. The robot's effector is mounted on satin grinding machine, which is equipped with a roller za grinding fleece and, next to it, a blade disc in a quick-release chuck.

Robotic workstation for shield polishing

The basis of the workplace is 6 axial robot, which is suspended from the cabin ceiling. The robot's effector is mounted on satin grinding machine, which is equipped with a roller za grinding fleece and, next to it, a blade disc in a quick-release chuck.

Robotic workplace for hardening and annealing of cartridge cases;

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

More about the device

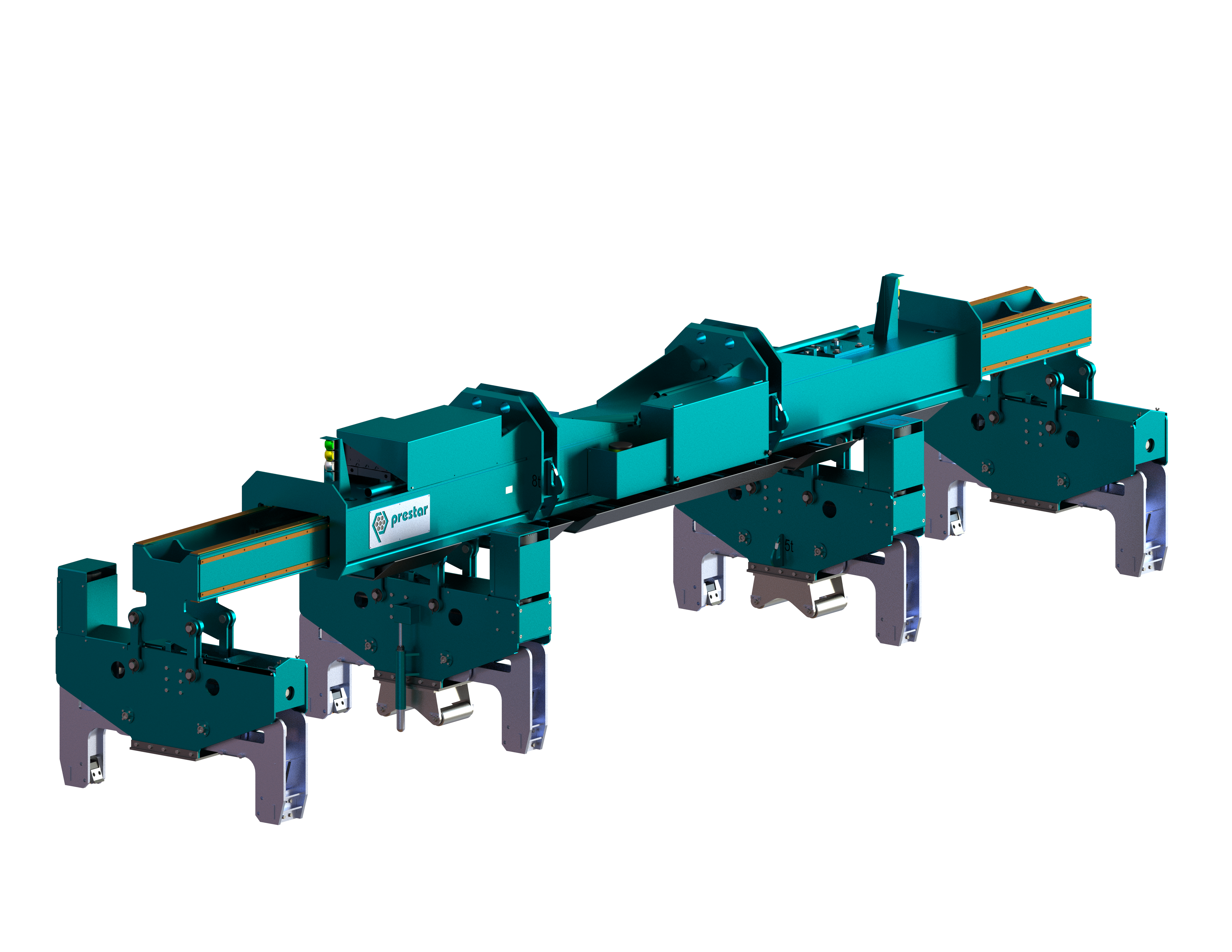

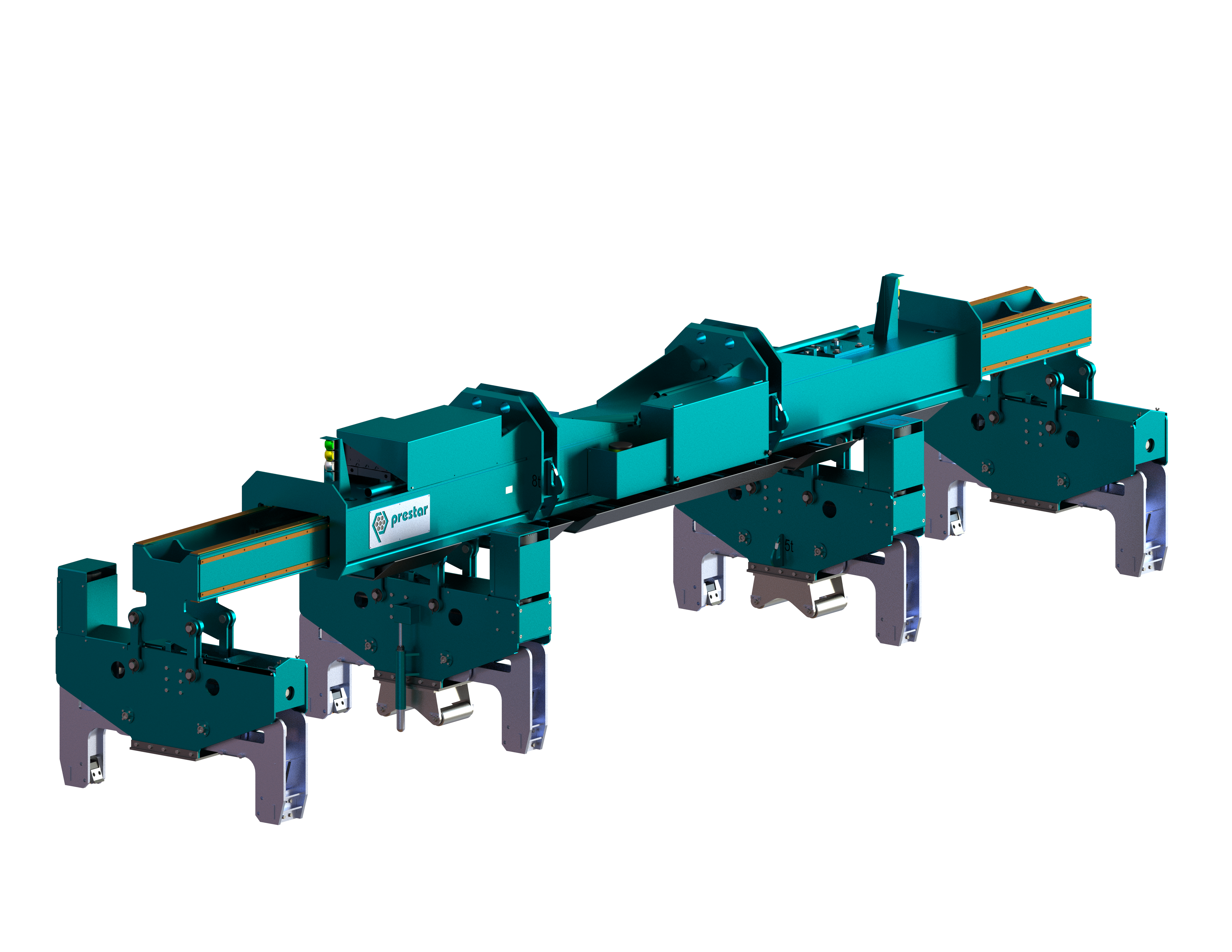

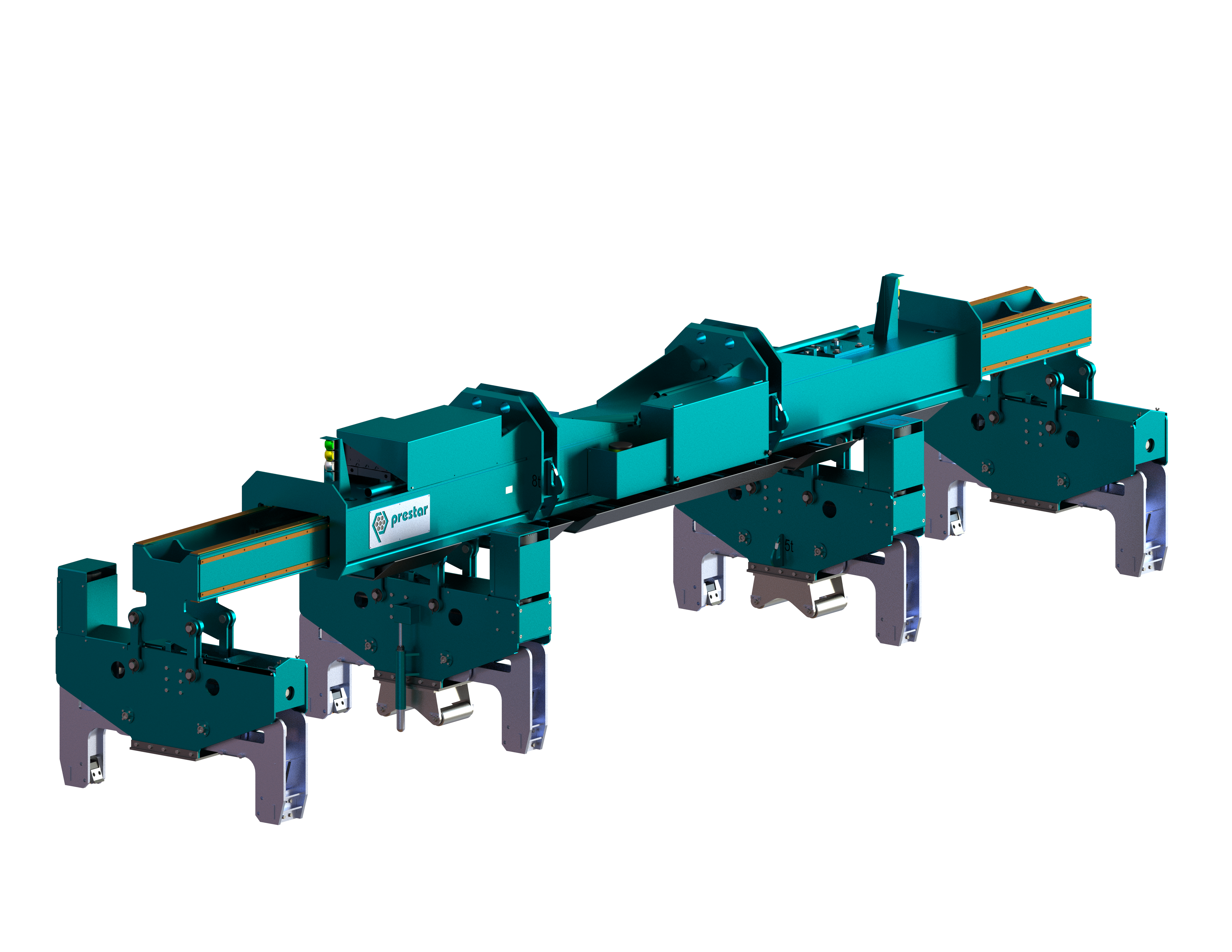

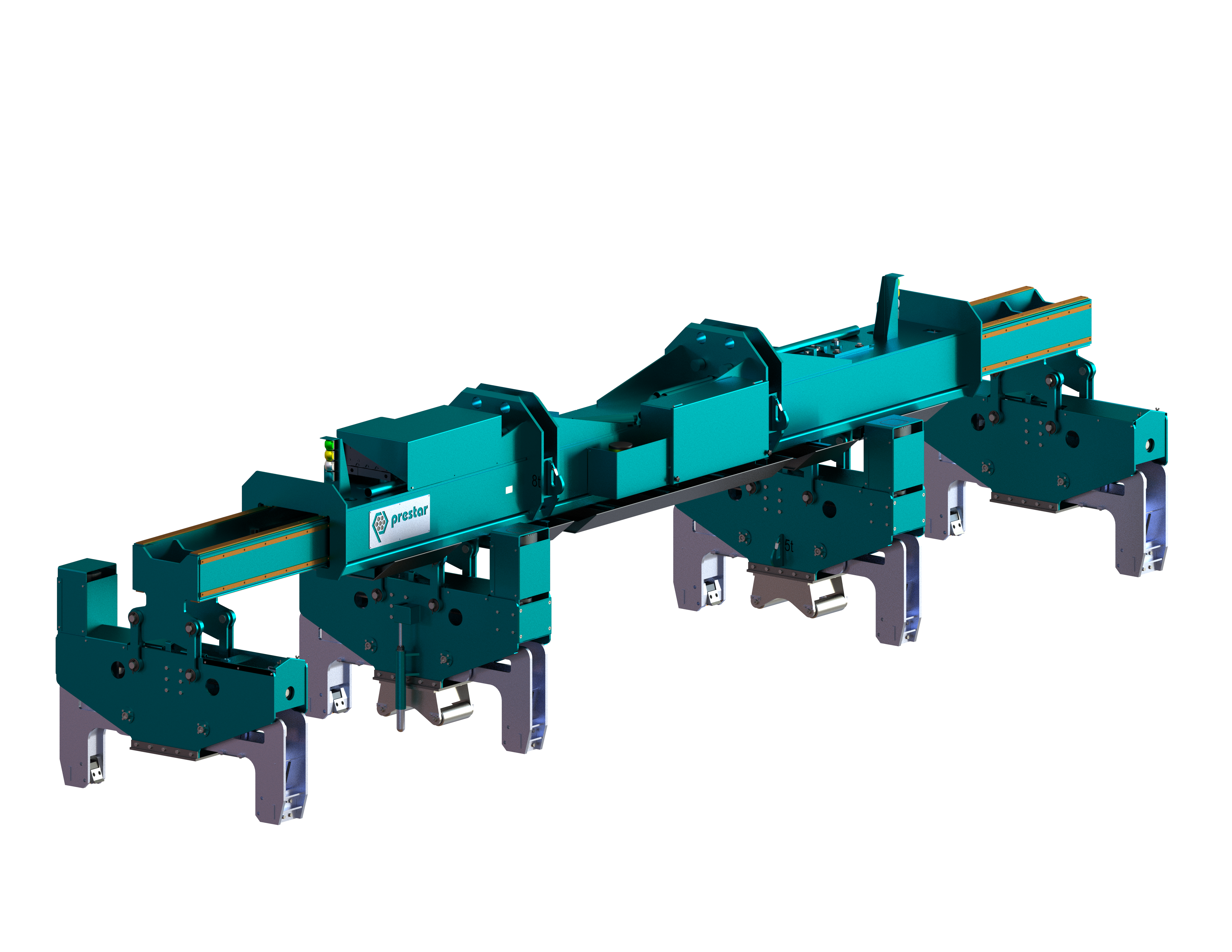

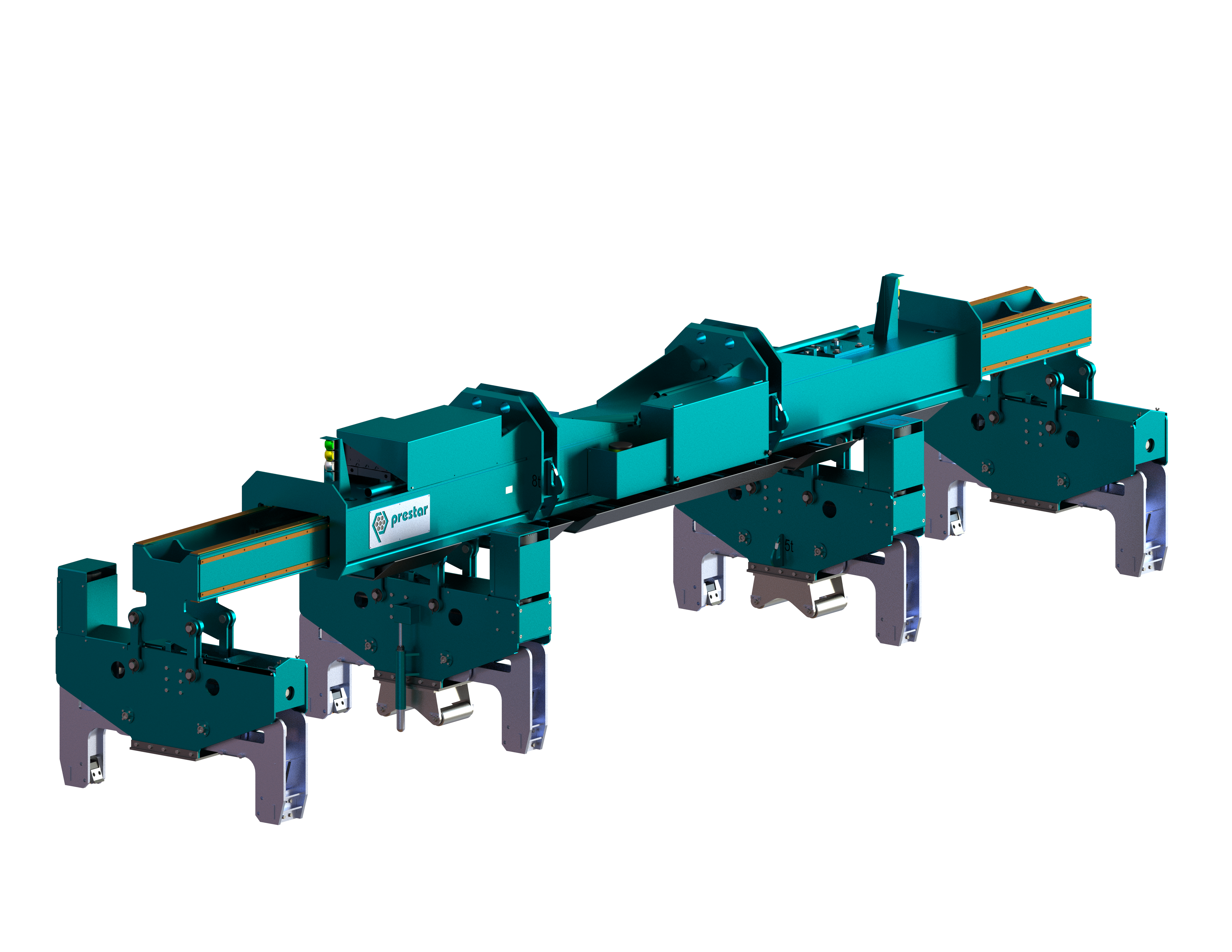

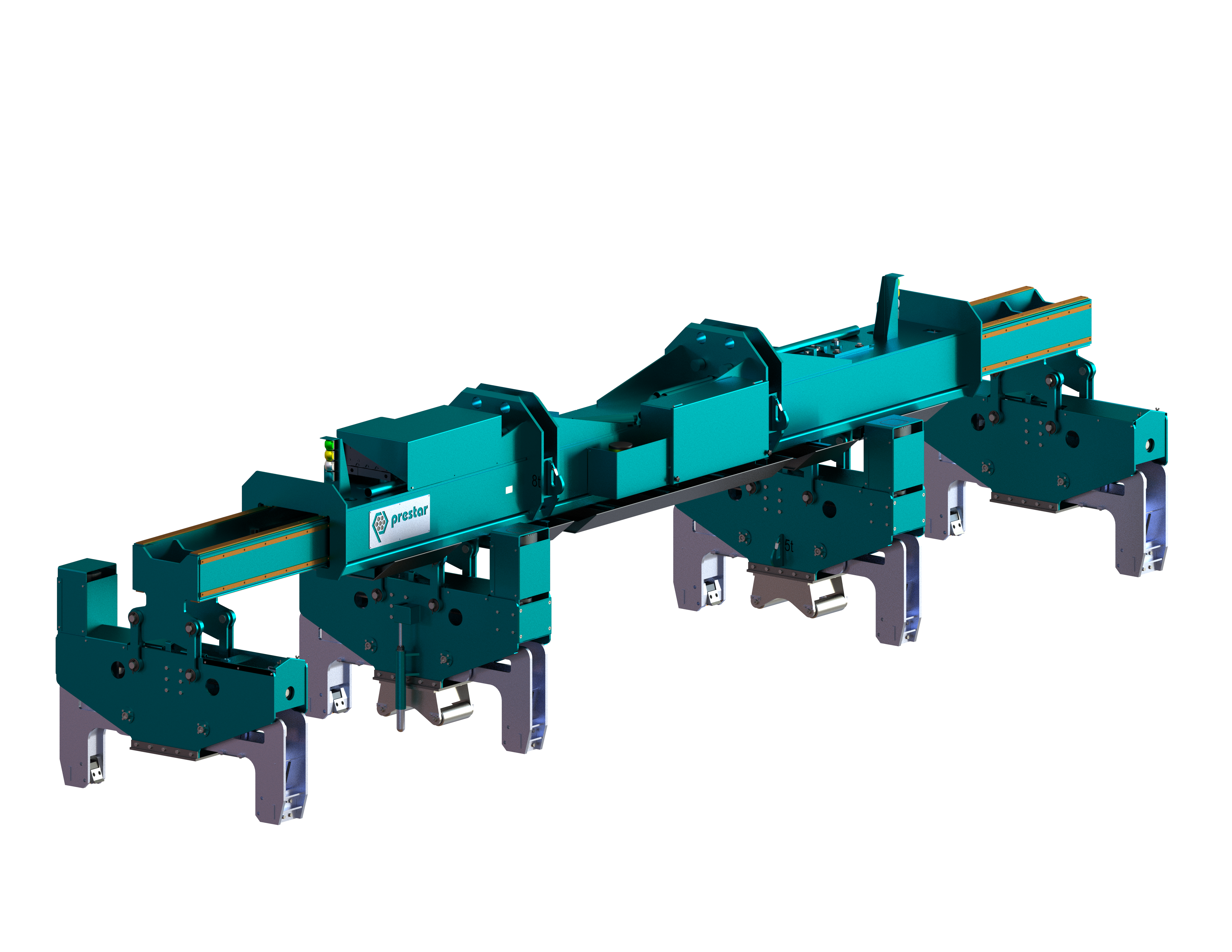

Linear positioning axes and systems

Complete solutions for various types of automation of handling processes. Standard modules can be combined as a stand-alone component or as an integrated axis system. including peripherals. A wide range of concept variants for mounting an actuator or robotic arm, either in gantry or floor-mounted versions.

Technical parameters of the machine

- Manipulator setting according to container size

- Can be used even at very low temperatures down to -40°C

- Equipped with a turntable for rotation around the vertical axis

- Telescopic arms for gripping 20" to 40" containers

- For hanging on crane ropes

Let's streamline the future together!

Linear positioning axes and systems

Complete solutions for various types of automation of handling processes. Standard modules can be combined as a stand-alone component or as an integrated axis system. including peripherals. A wide range of concept variants for mounting an actuator or robotic arm, either in gantry or floor-mounted versions.

Name of device

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

More about the device

Name of device

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

More about the device