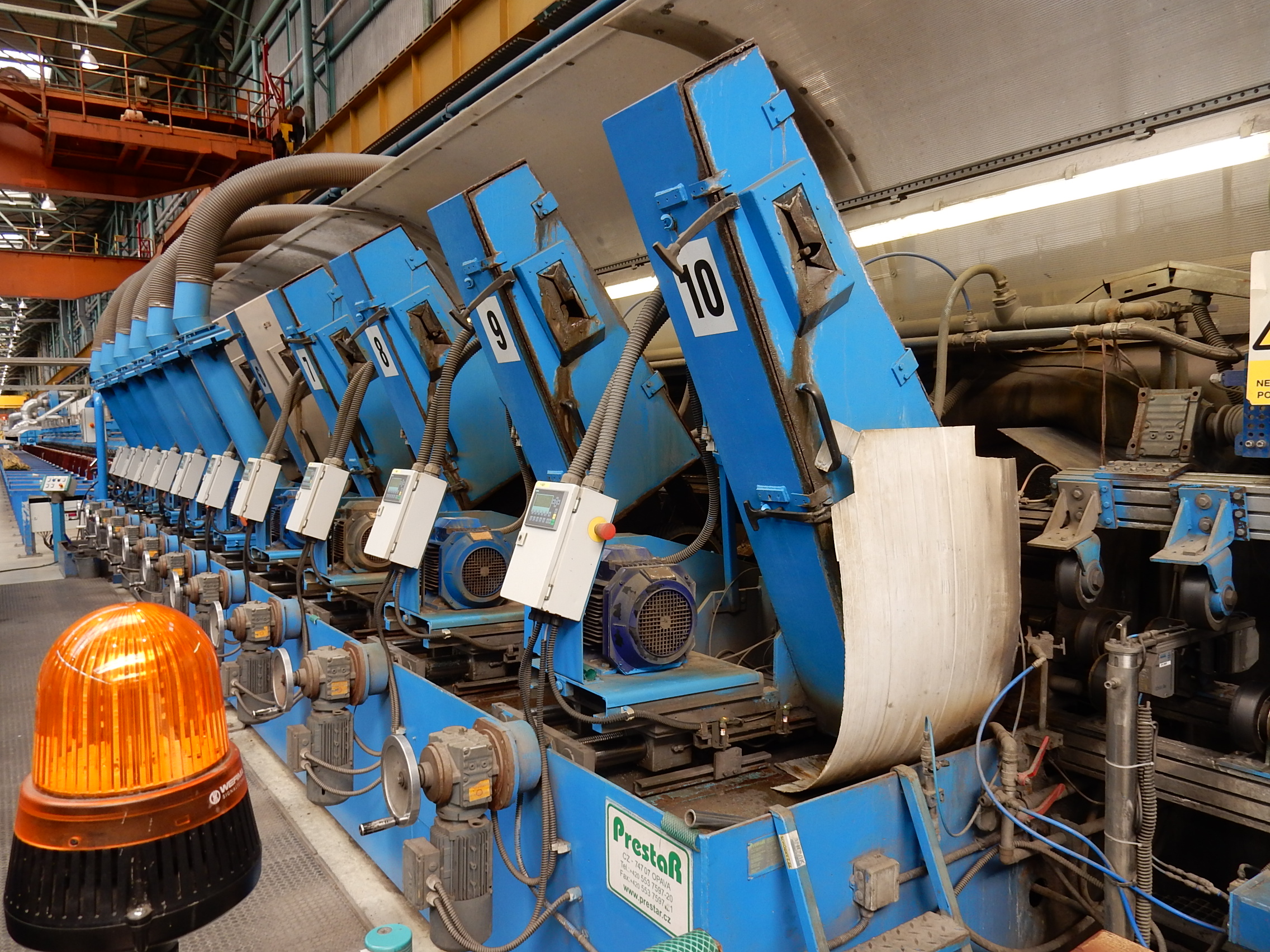

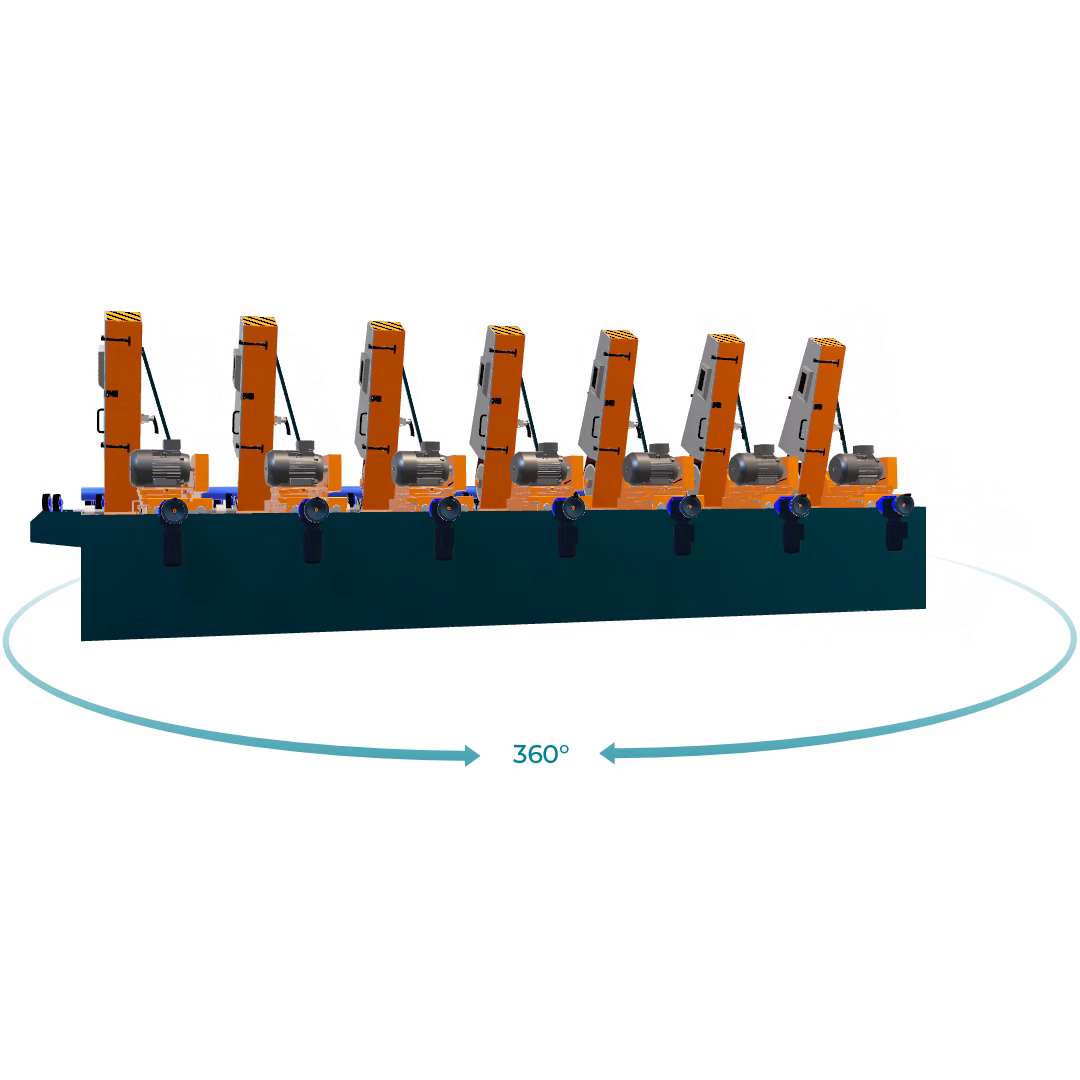

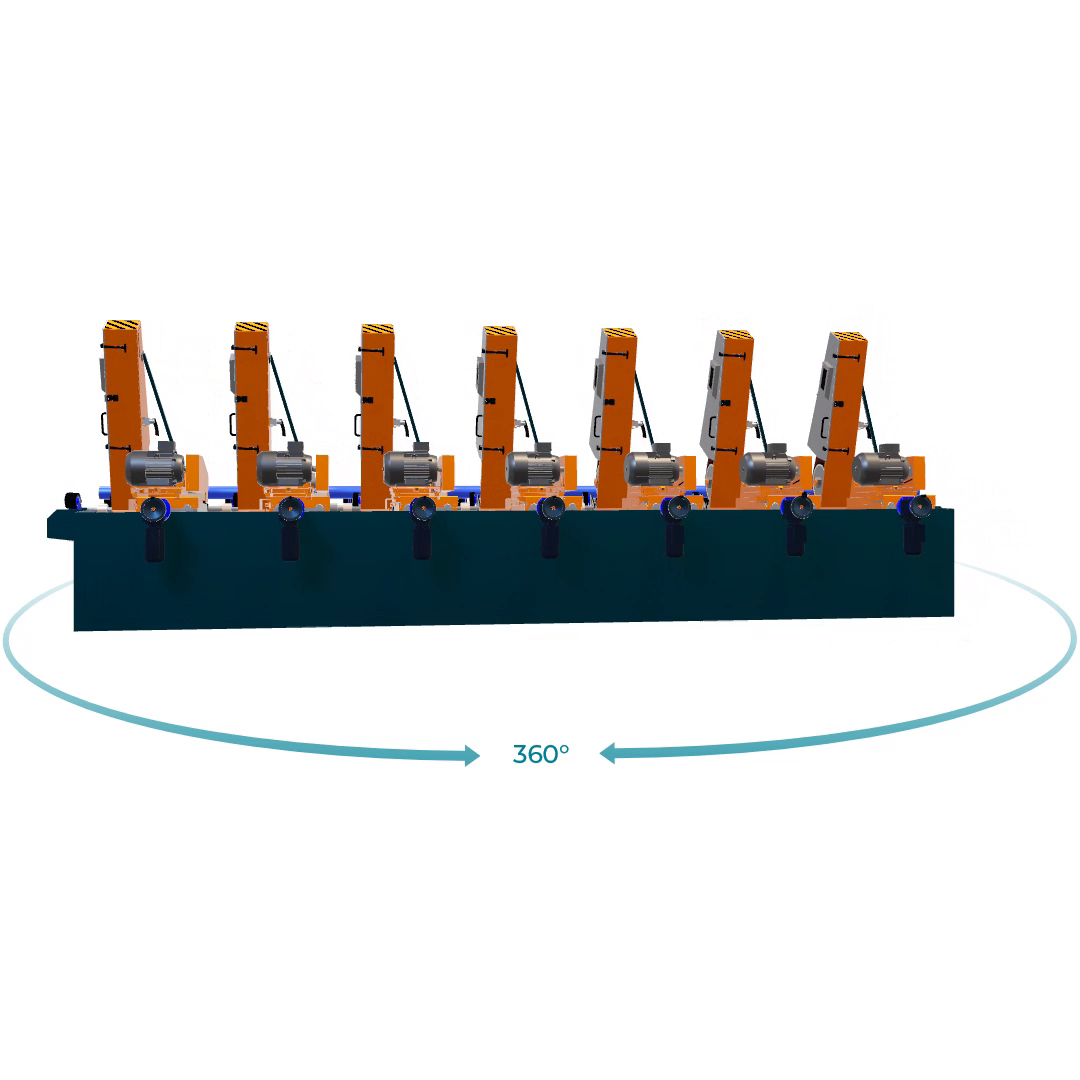

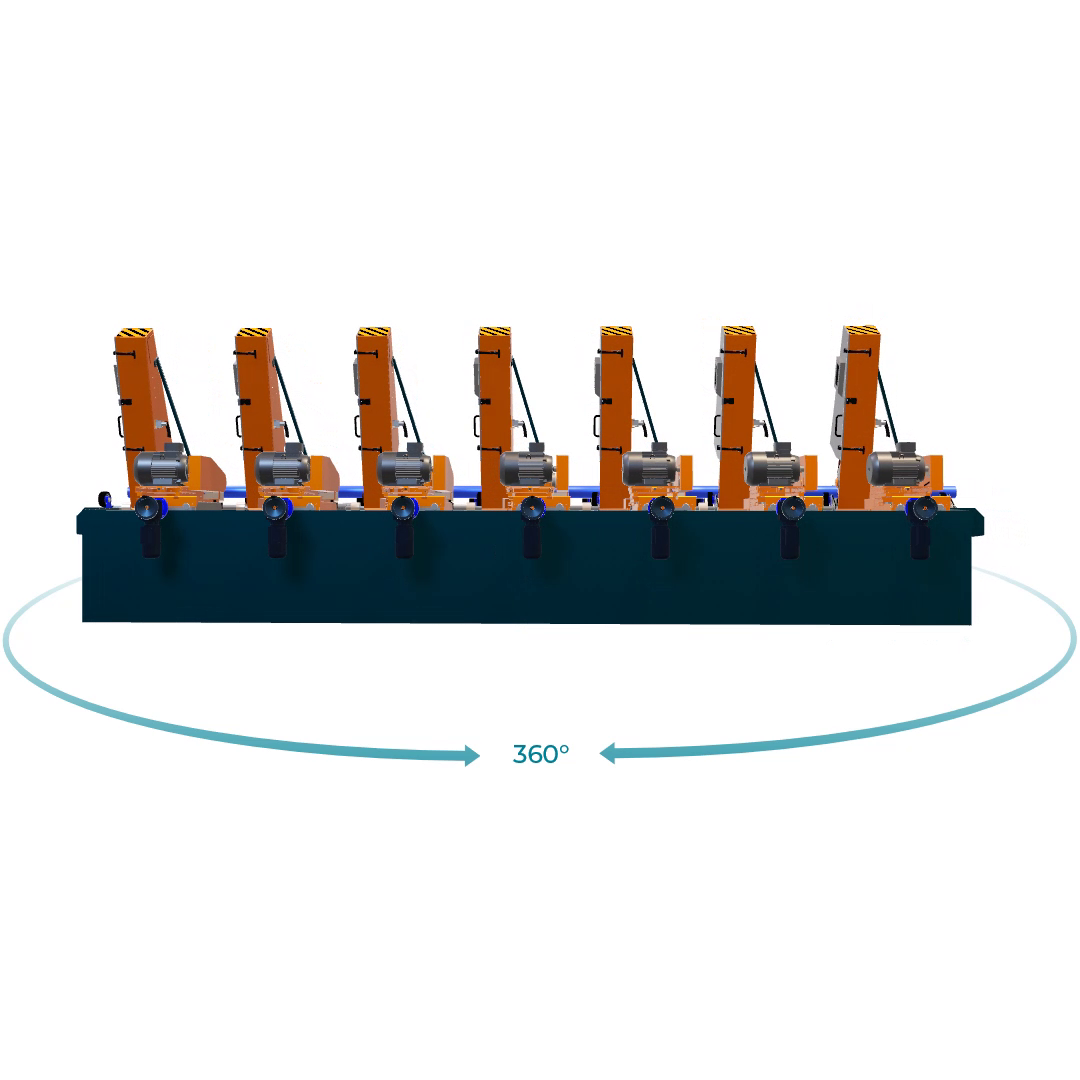

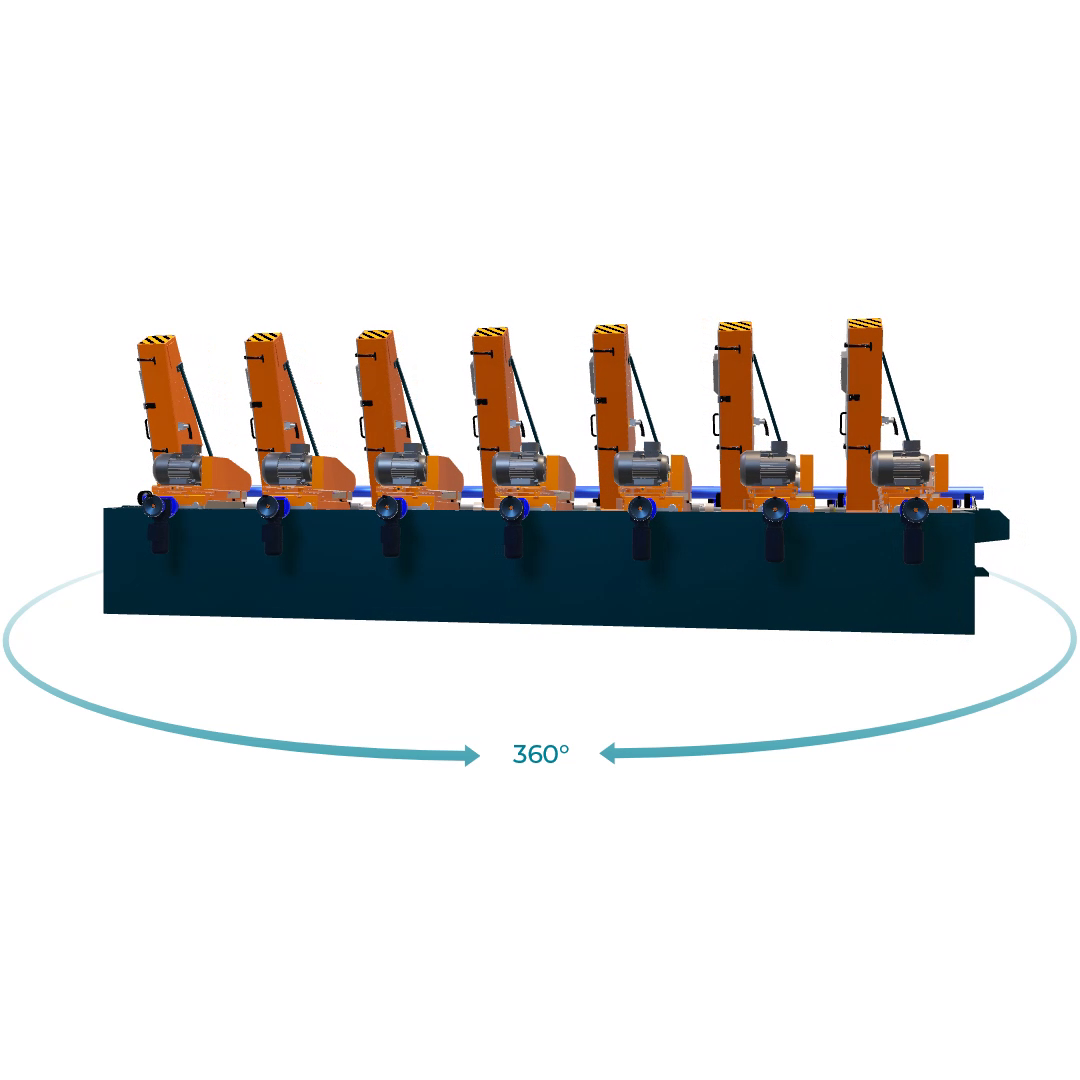

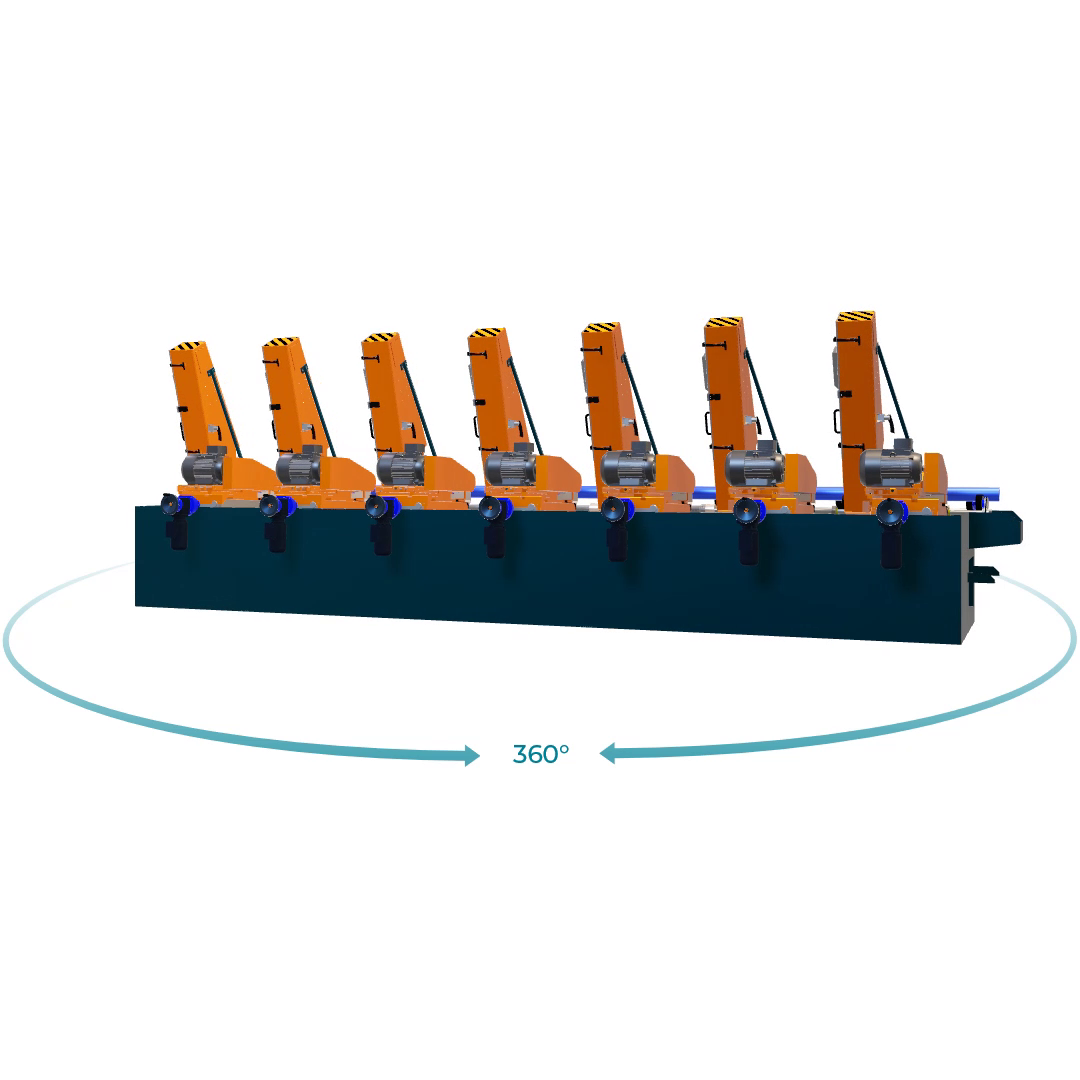

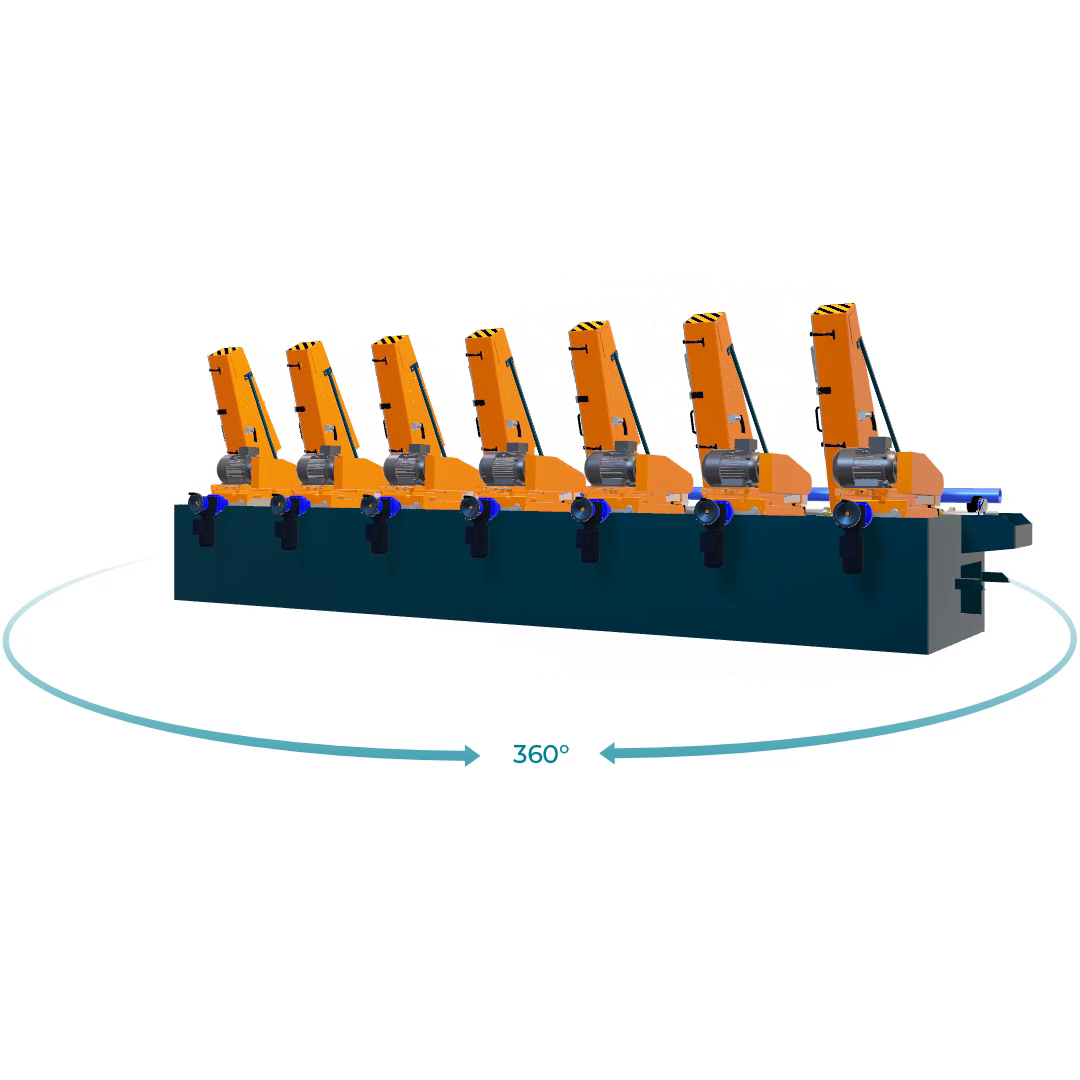

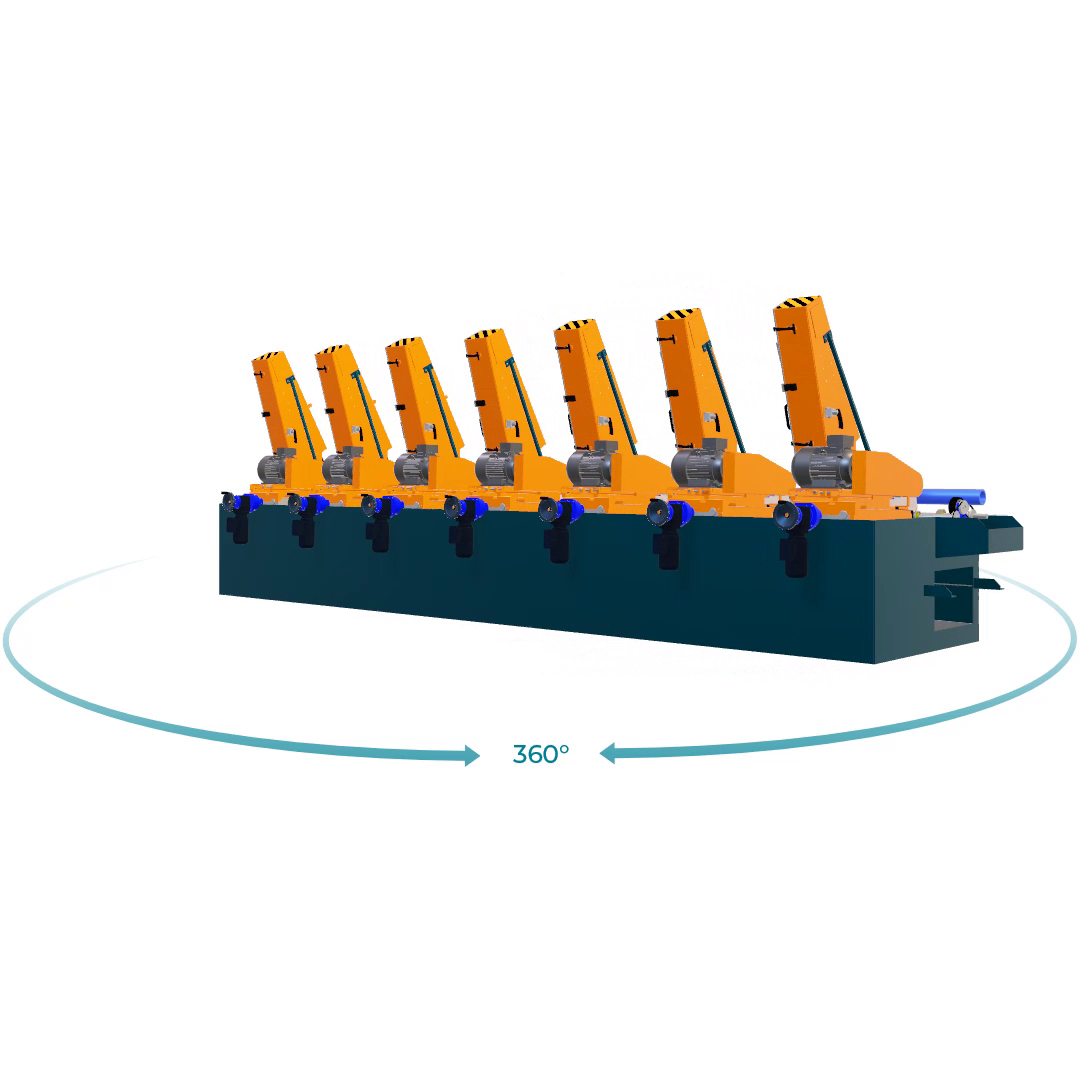

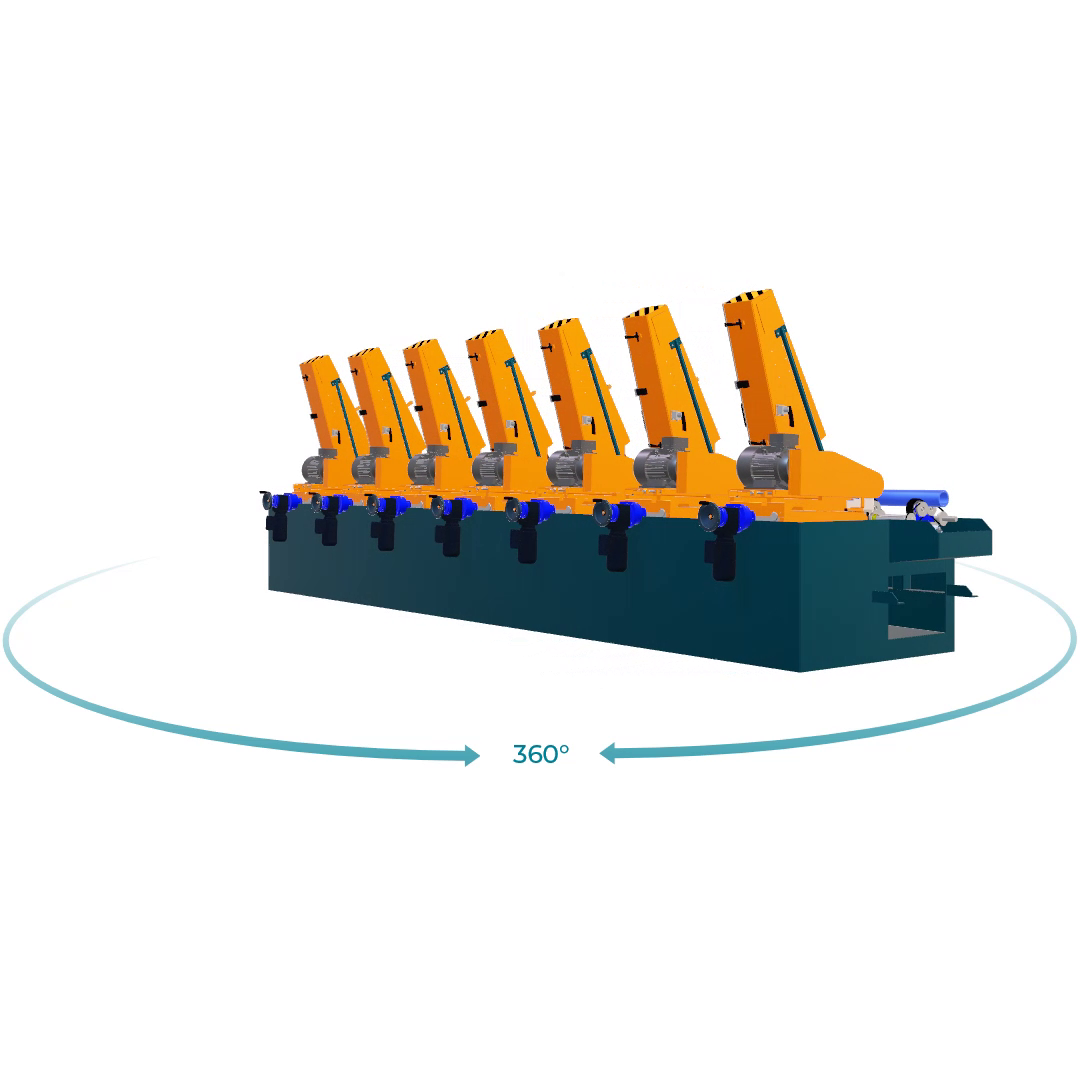

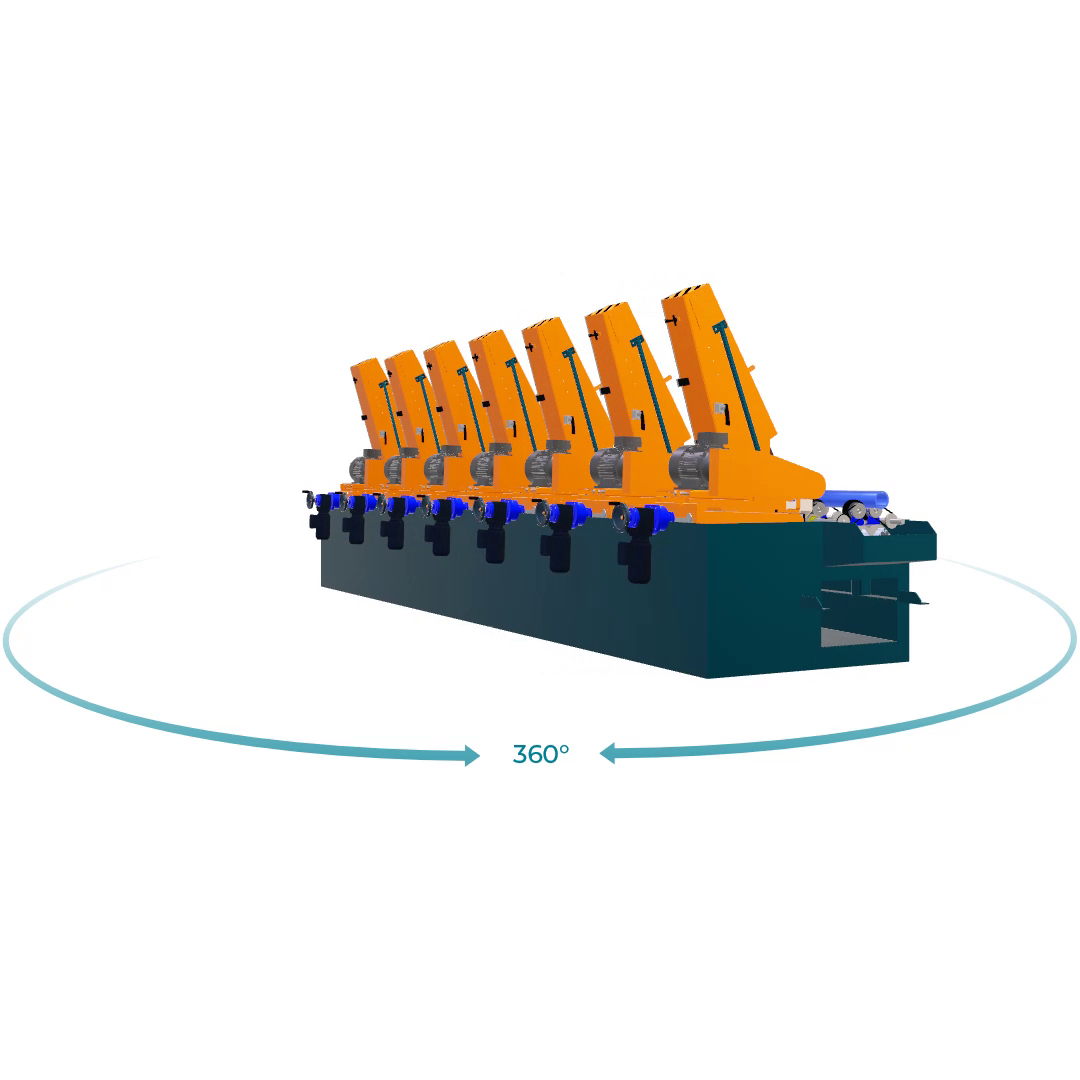

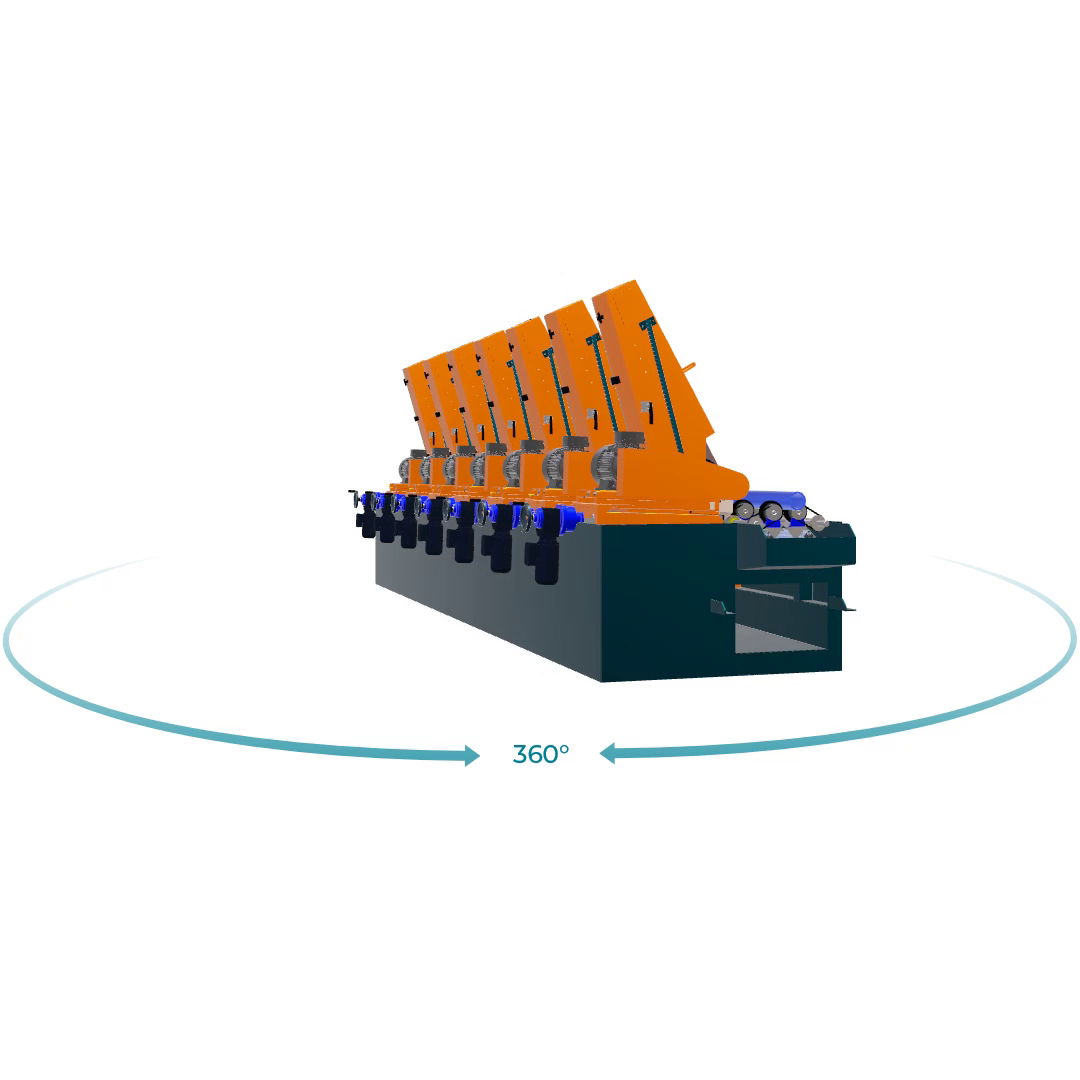

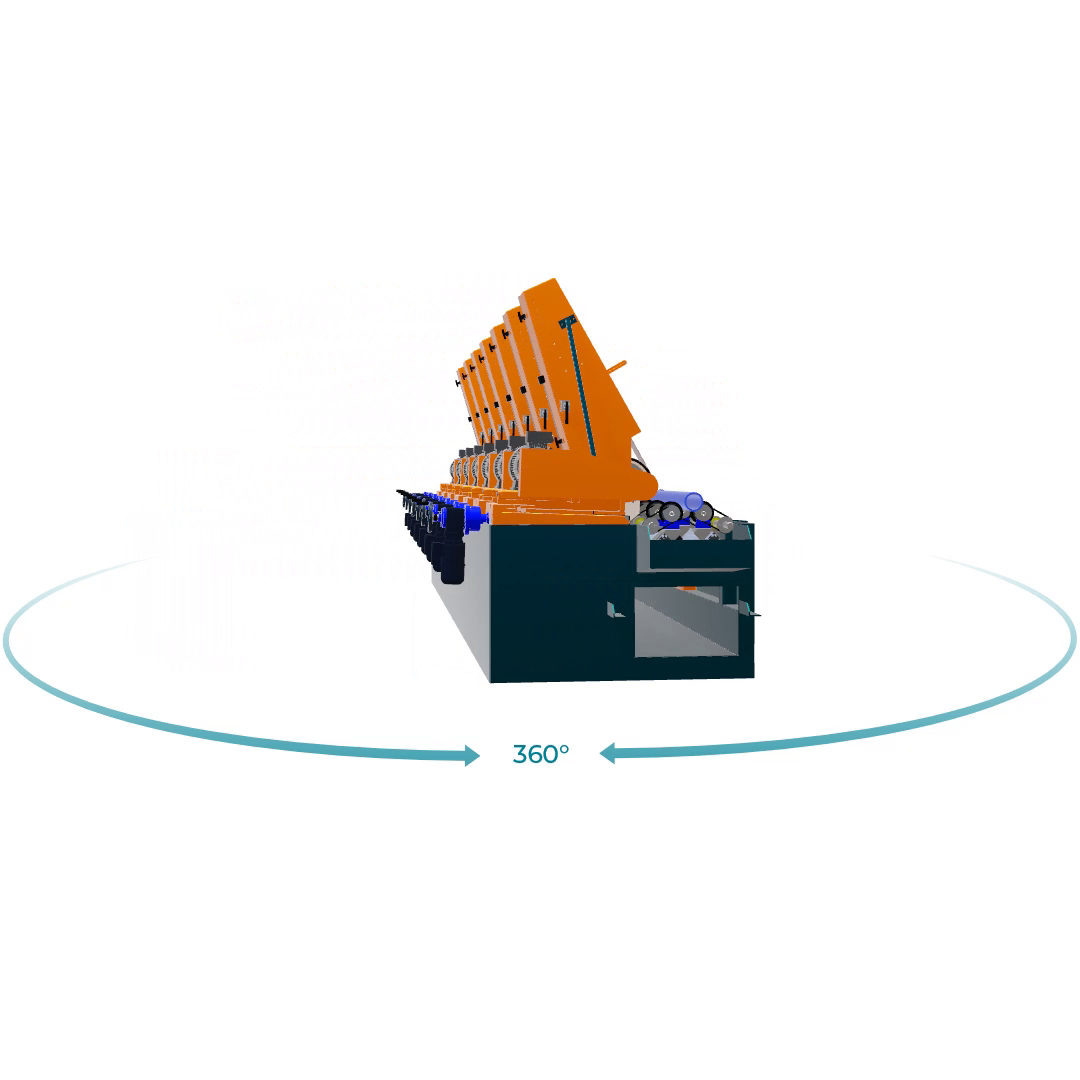

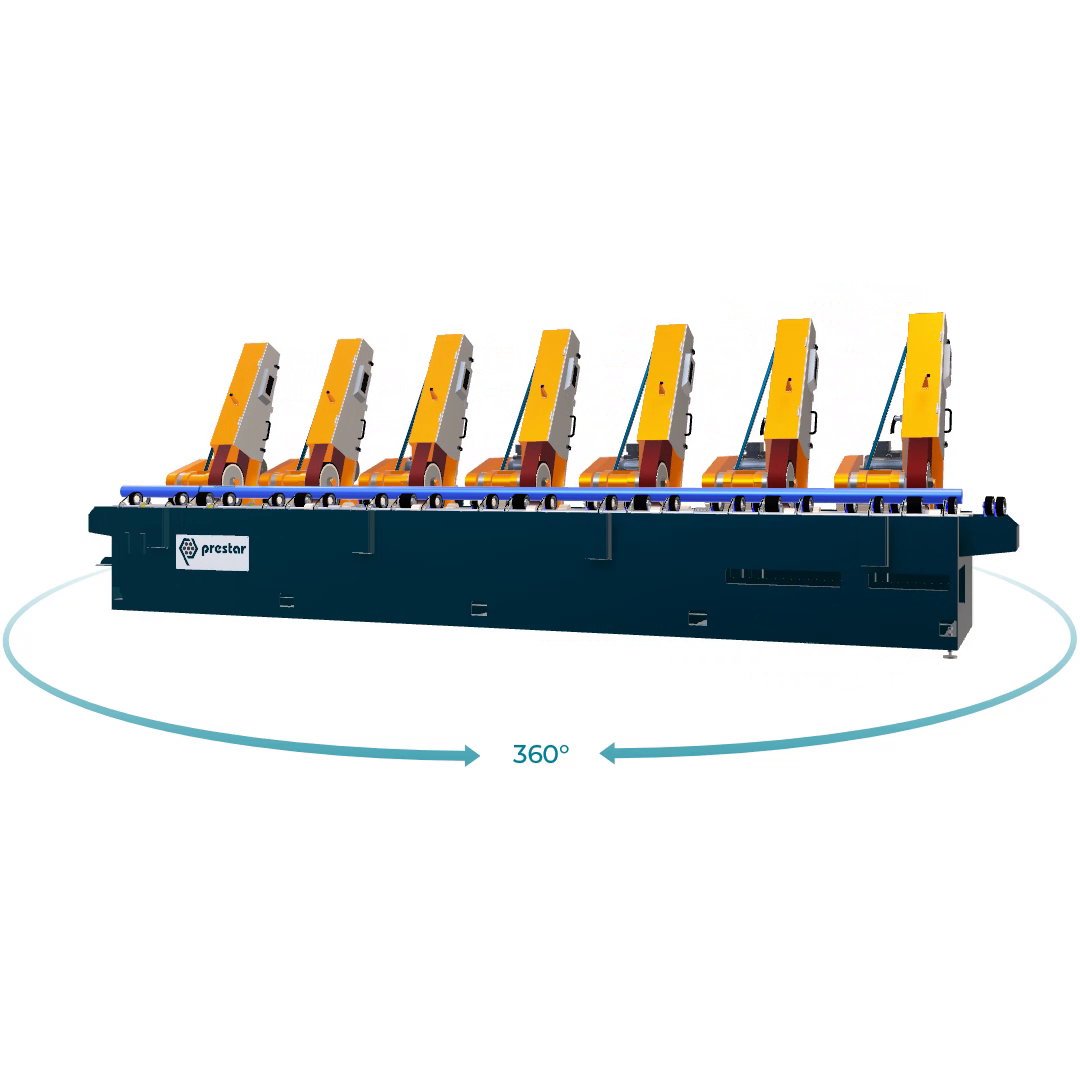

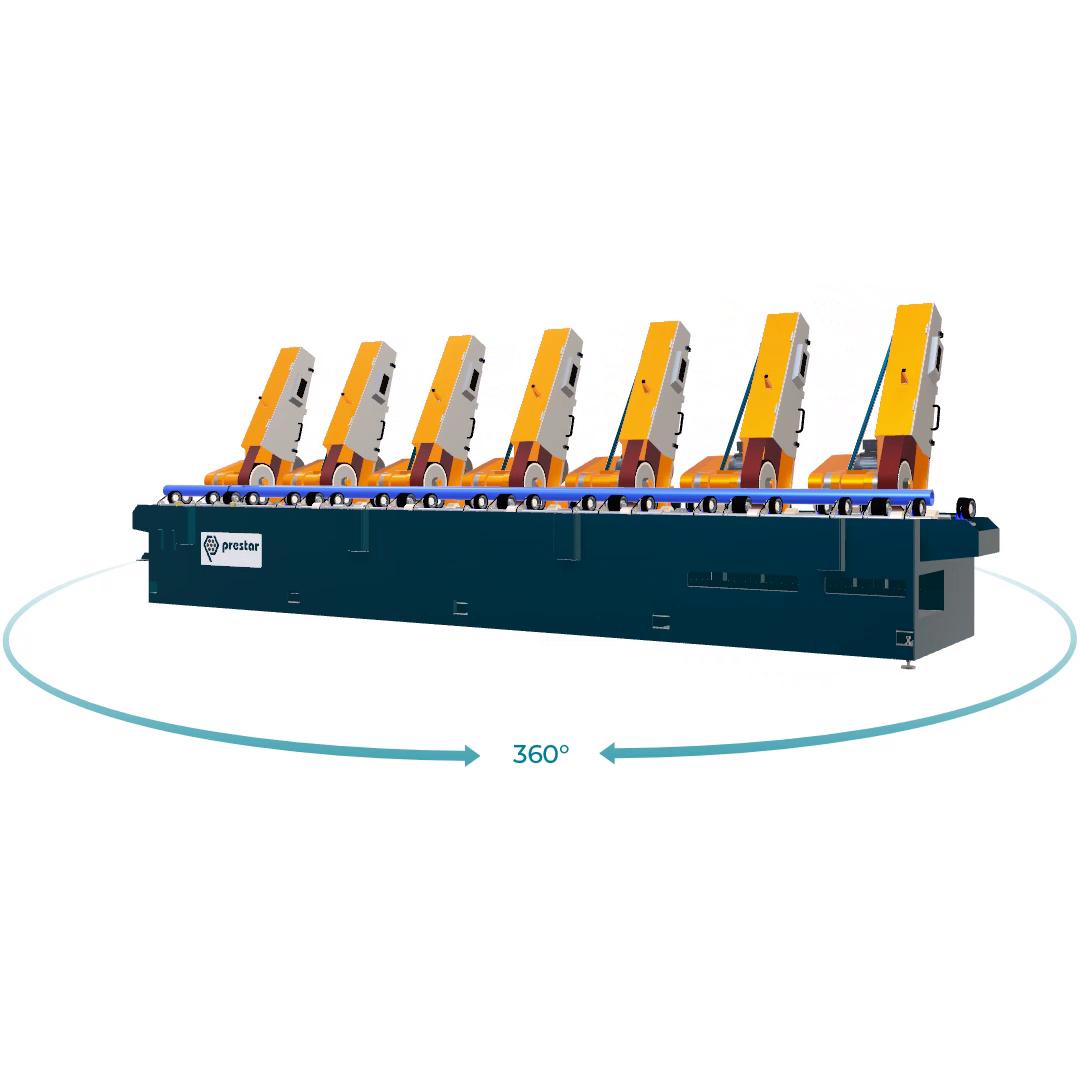

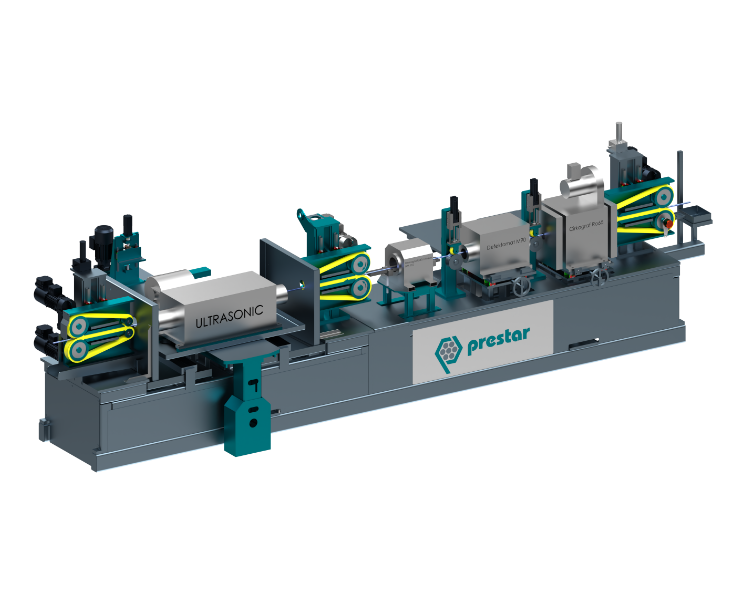

Centerless pipe grinder

Description of the device

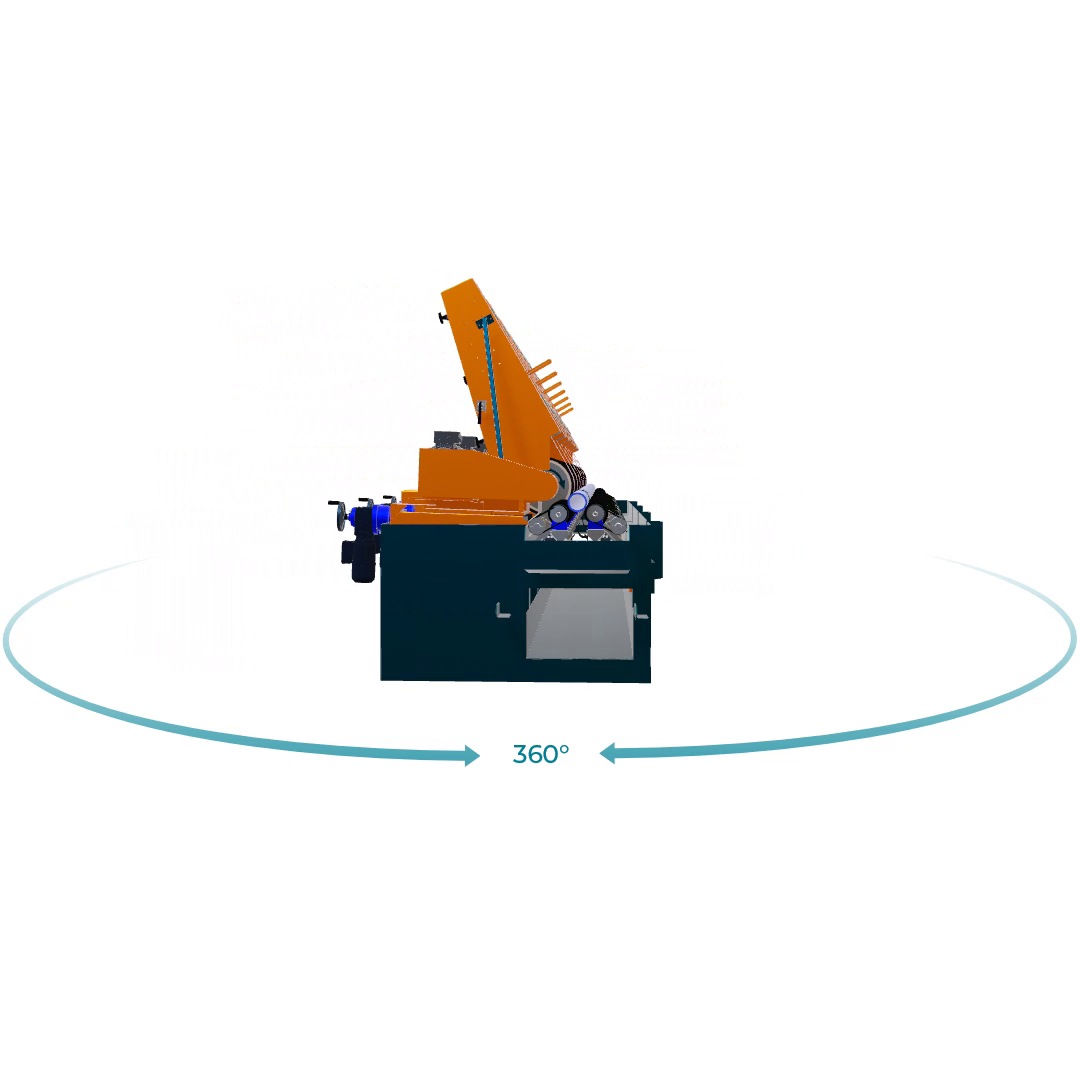

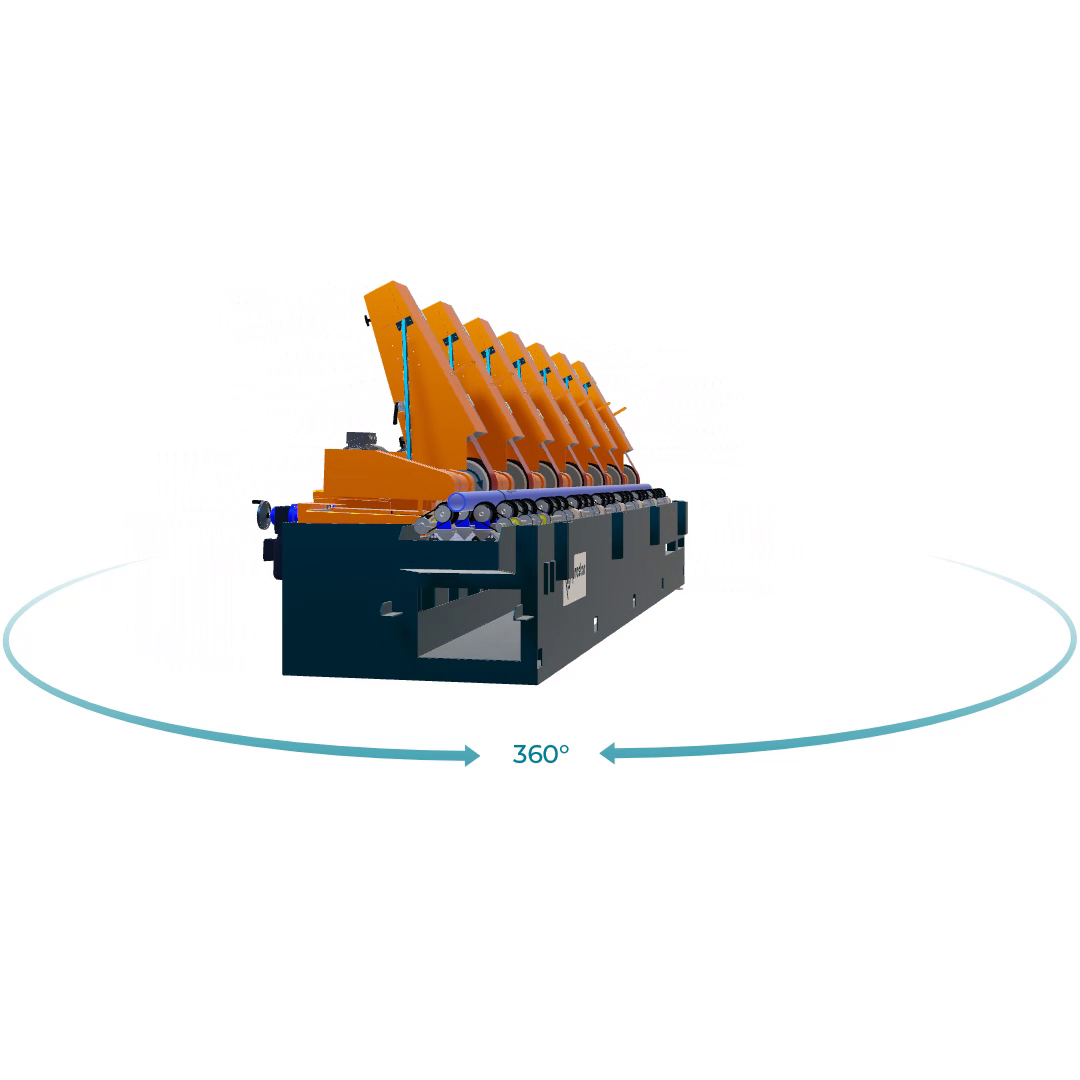

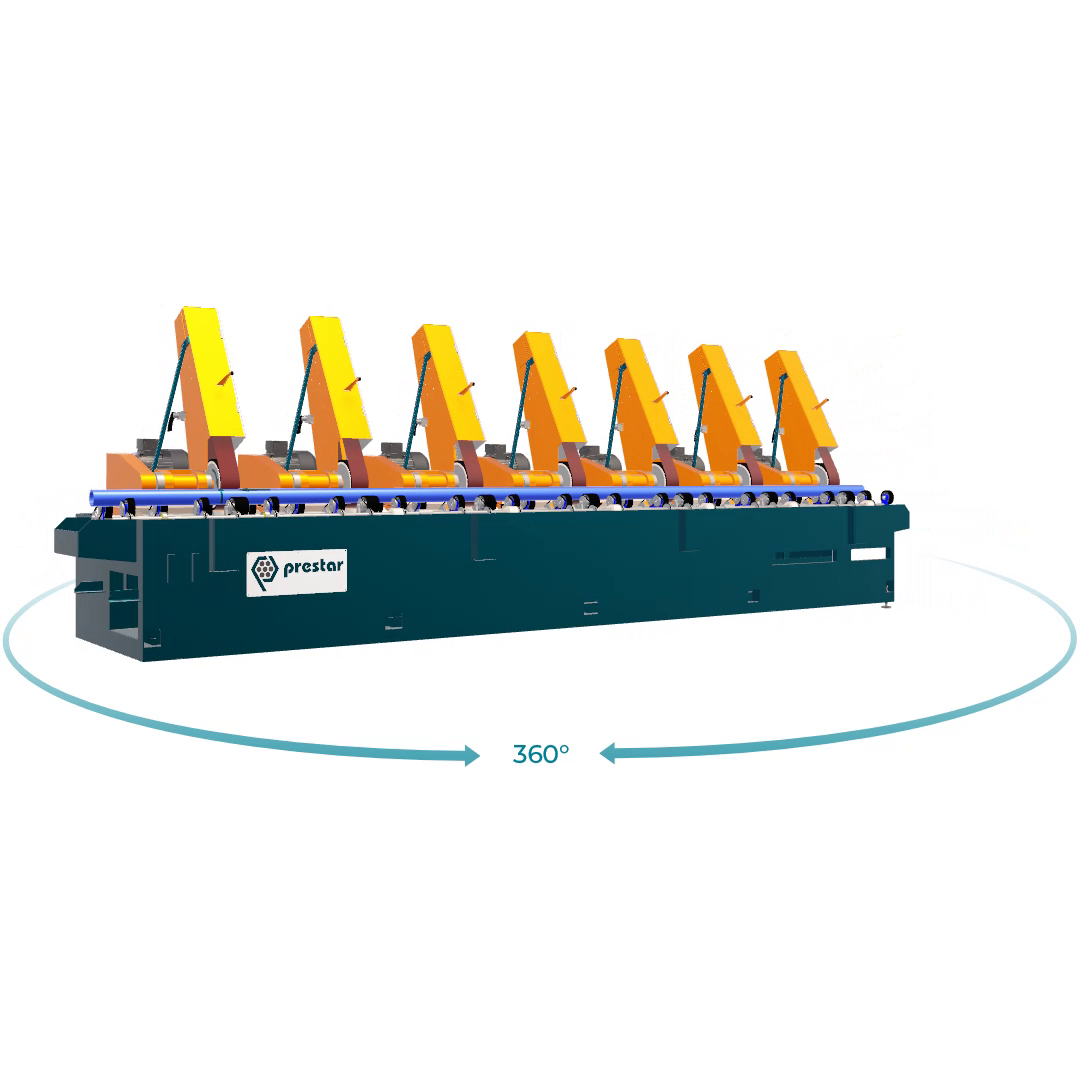

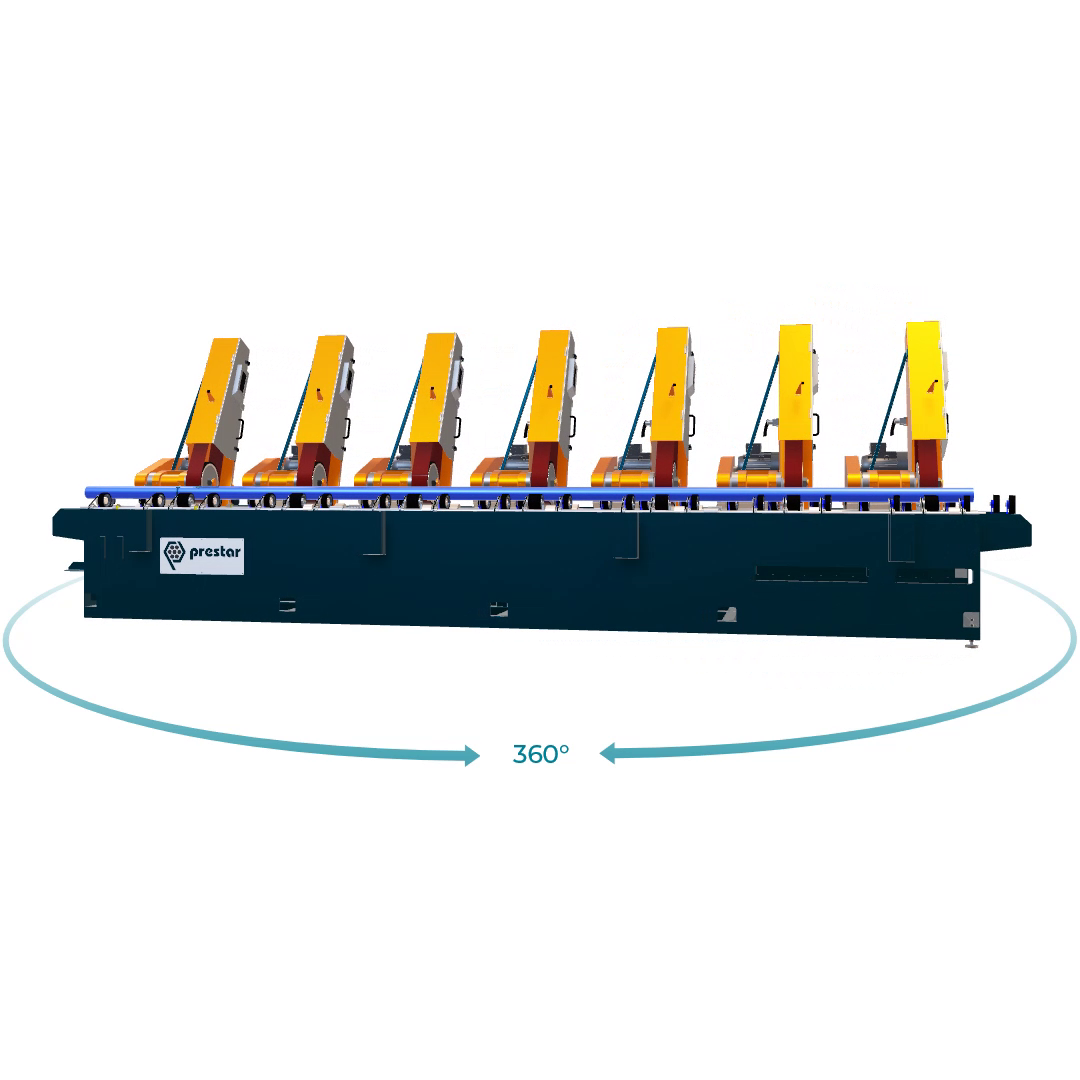

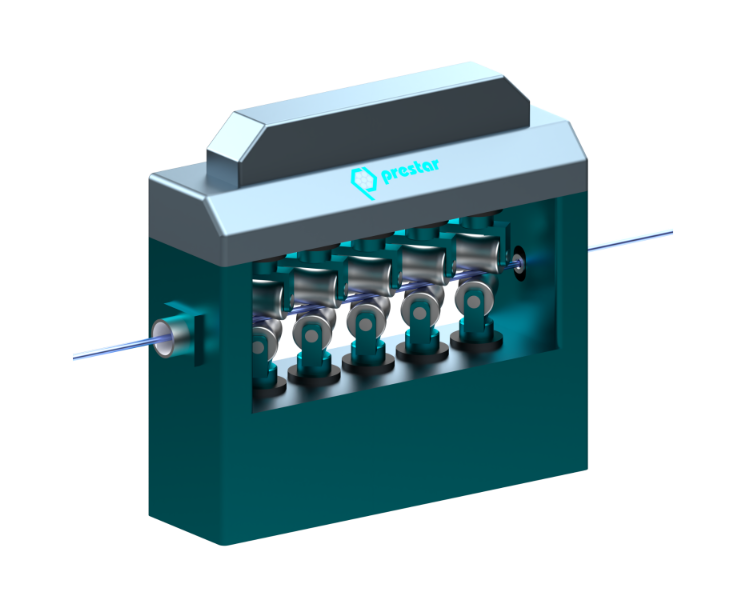

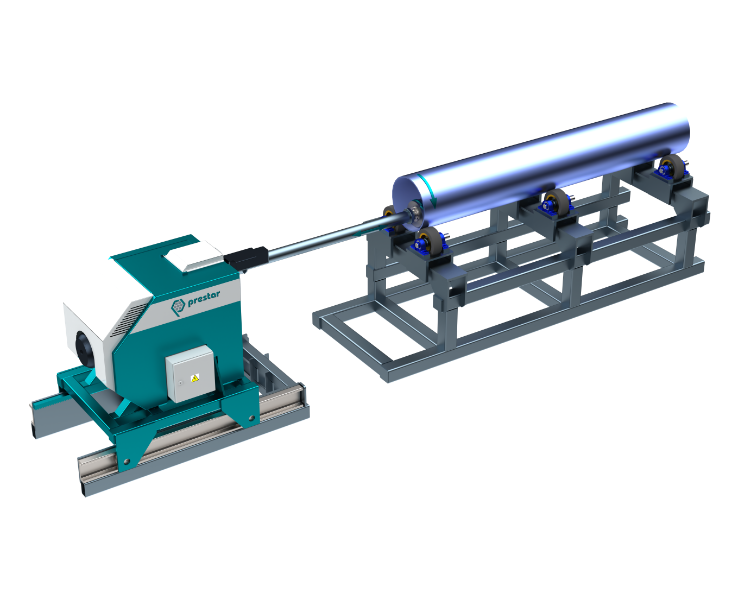

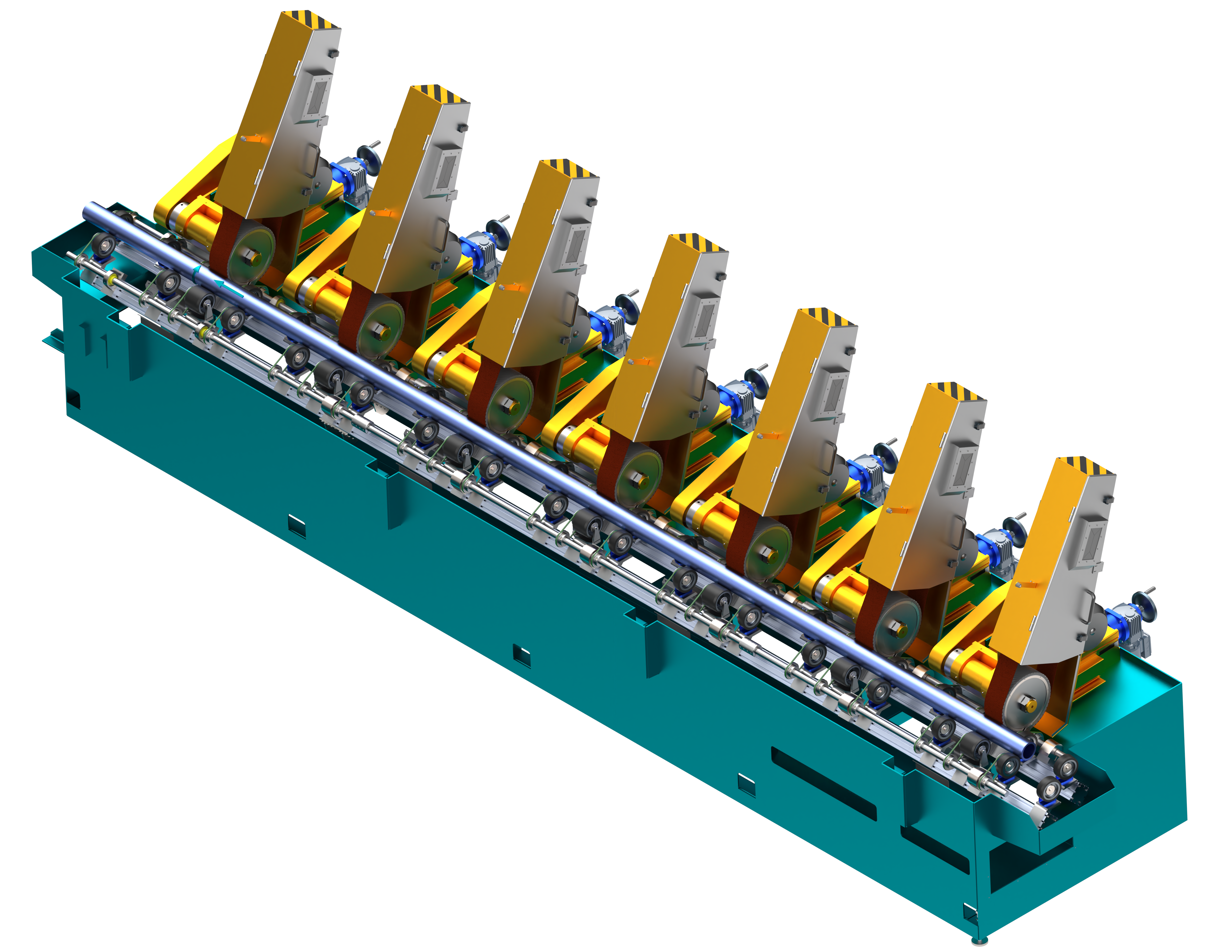

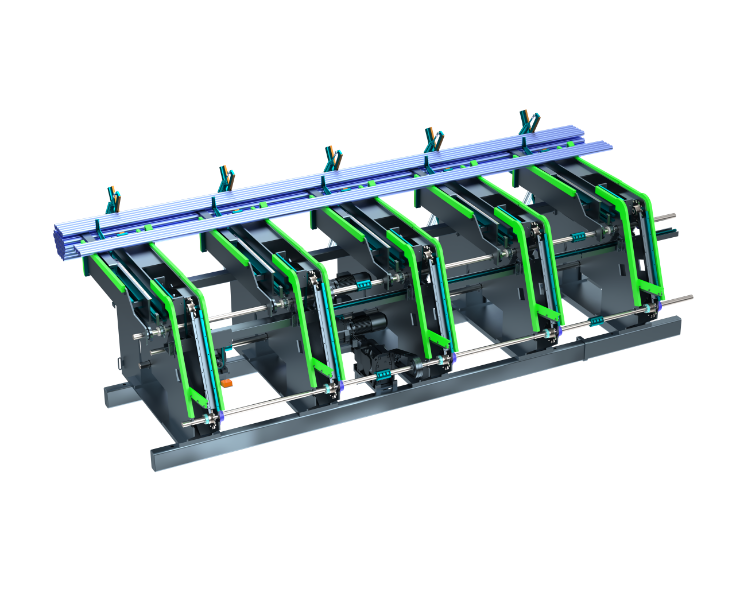

Cold drawn and cold rolled tubes require the outer surface to be ground down to remove surface defects and to achieve a high surface quality. The pipe is inserted into an infeed conveyor with driven radial rollers, which imparts rotation to the pipe and moves the pipe into the grinding machine. The tube passes along a series of up to 14 grinding stations equipped with grinding belts. Each grinding station is equipped with its own pressure which can be adjusted by the operator. Grinding can be carried out wet or dry.

Wet grinding grinds the material with a constant supply of coolant. The ground material is rinsed into the tub and conveyed out of the tub by a worm shaft. The water with the abraded material is filtered in three stages. Magnetic filter, fabric filter and mechanical separator. The solid residues are deposited in an attached pallet and the filtered water is reused for grinding.

In dry conditions, the grinding stations are equipped with a suction with filter station. Furthermore, the grinding stations are located in a dust-tight cabin.

Na výstupu z brusky trubka vyjíždí do výstupního dopravníku s radiálními válečky. Následuje vyklopení trubky na následné technologie.

Technical parameters of the machine

| Diameter of pipes: | 6 – 90 mm |

| Pipe lengths: | 1,5 - 40 m |

| Surface quality after grinding: | to Ra 0,4 |

| Grinding belts: | 150 x 3000 mm or according to the user's belt range |

| Grinding method: | wet or dry |

| Pressure of grinding belts: | pneumatic |

| Tensioning of grinding belts: | pneumatic |

| Belt grinding speed | 30 m/s |

| Pipe axial feed rate: | 2 - 40 m/min with infinitely variable control |

| Replacement of grinding belts: | Easy access to abrasive belts |

Other equipment of the machine

- Continuously variable belt grinding speed control

- For wet grinding, the grinder is equipped with a magnetic separator and a fabric filter

- For dry grinding, the grinder is equipped with extraction and filter stations

- Conveying and handling technology in front of and behind the grinder

- For material removal measurement, the grinder can be equipped with continuous monitoring of material removal from the pipe surface

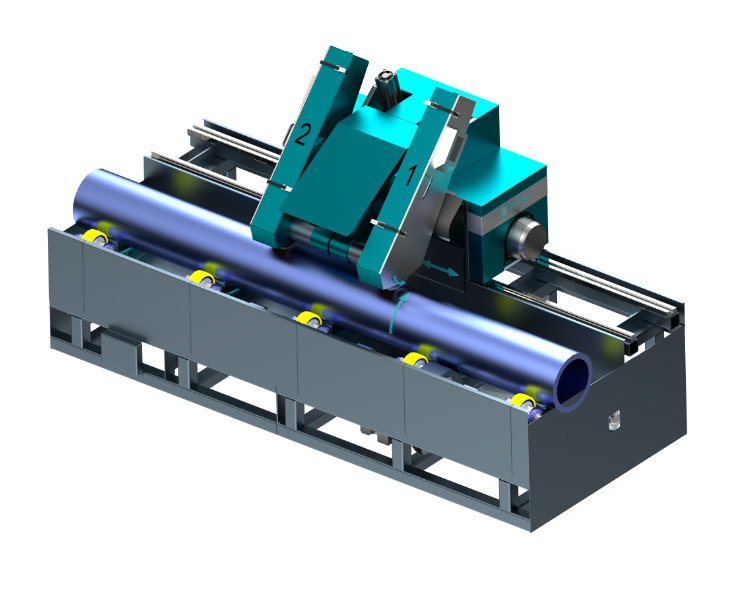

- For pipe profile measurement, the grinder can be equipped with a continuous ovality measurement

- For measuring the length of the processed pipe, the grinder can be equipped with a non-contact length measurement

- Extended visualization with an emphasis on intuitive and detailed display of operating states and the place of failure of the grinder.

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine HMI to minimize service times

- Collection of agreed production parameters with automatic saving, display and data export.

Straightening machines

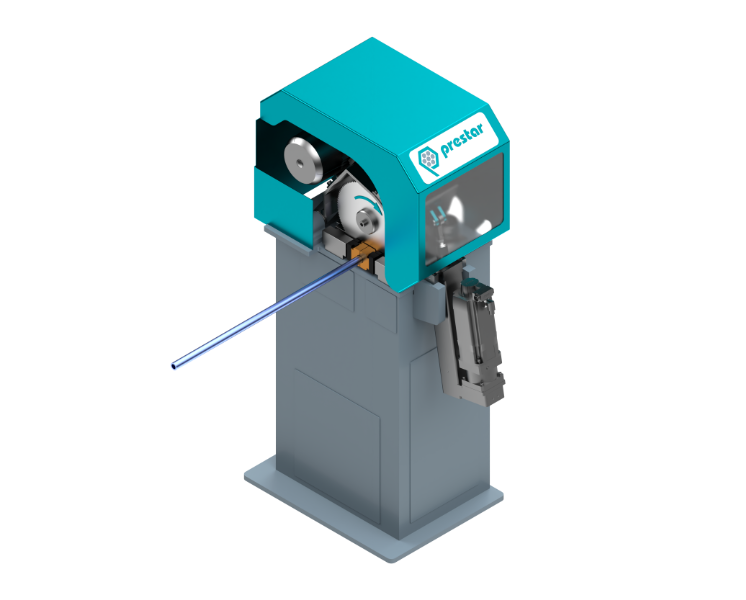

Internal pipe grinder

Centerless pipe grinder

External stationary pipe grinder

Flying saw

Circular saw

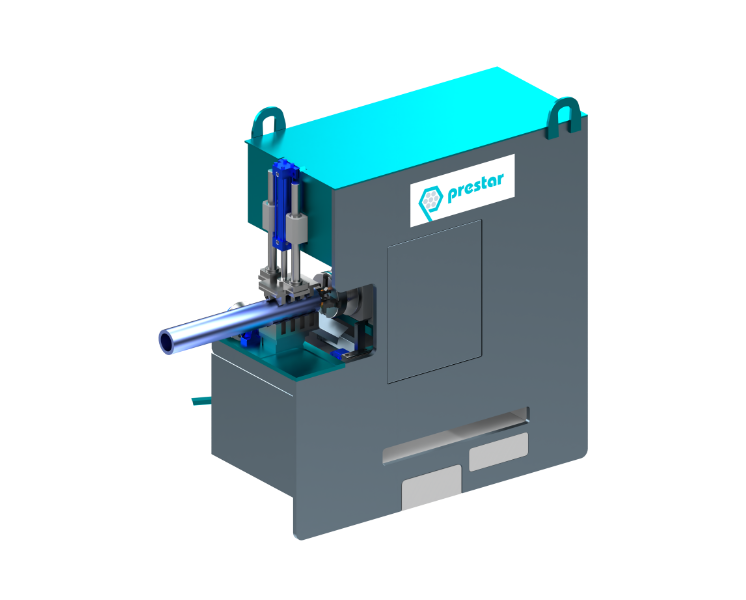

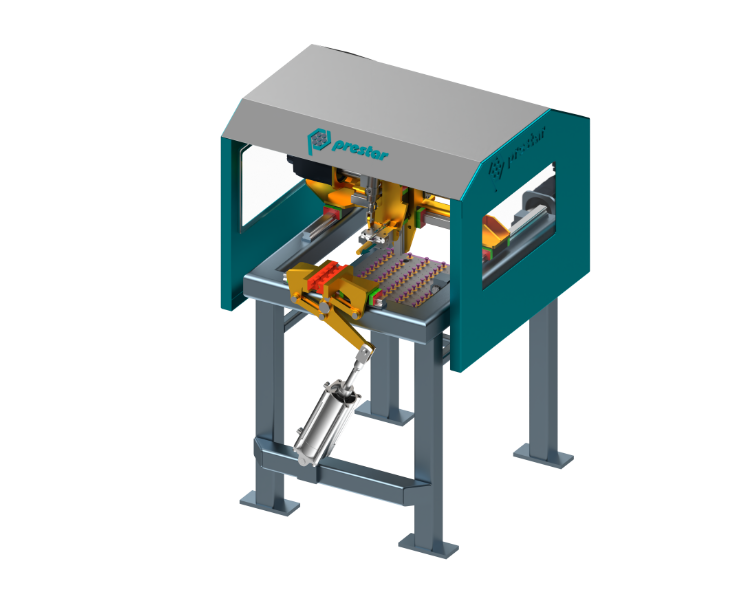

Chamfering of pipes

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT