Industry automation

Let‘s streamline the future together!

As the main contractor, we provide complex services for the implementation of a smart factory with the principles of Industry 4.0 from design, sensor technology, PLC, SCADA, MES system, to interconnection with the ERP system.

We can advise you on the collection of relevant online data, and vertical and horizontal communication across the company. Be an example of production automation for others.

Our goal is to find a suitable solution with the aim of higher production efficiency with a short return on investment.

EPR

H-level+: customized connection with ERP / MES / IT systems based on OPC-UA, MQTT, TCP-IP, Modbus TCP

MES

MES+: modular system for smart factories and online collection of relevant data, production monitoring, production planning and control, maintenance management, quality management and traceability, production visualization, performance analysis

SCADA network

SCADA+: control rooms for complex lines, the application can visualize data from all sensors and actuators on the line

Mobility+: Remote control panel or industrial tablet for maintenance, service, local control, client visualization application, mirror image of control room application

Digital Twin+: a virtual model designed to accurately reflect a physical object. Updated from real-time data, uses simulation, machine learning and reasoning to help decision-making

PLC

IoT+: secure internet connection, via the customer's network or via a mobile operator will enable remote management and extended package functions (Diagnostics +, Service +, Vibro +)

RFID+: operator logging, component monitoring according to the selected production method

Servis+: interactive procedures for service activities and maintenance (videos, PDF on HMI panels), display of spare and wear parts, send an email with a request for delivery to the Prestar service center or customer (IoT+ needed).

Vibro+: vibro-diagnostics, data collection for predictive maintenance, email notifications

Diagnostics+: interactive diagnostics, in case of a fault it will refer graphically to the place on the line, instructions / procedure how to eliminate the fault

Data+: data archiving locally based on MS SQL

Data Cloud+: data cloud archiving solution

Sensor

Optimization+: trial operation after acceptance of the line with the participation of a programmer with extended training of operators and optimization of the production process

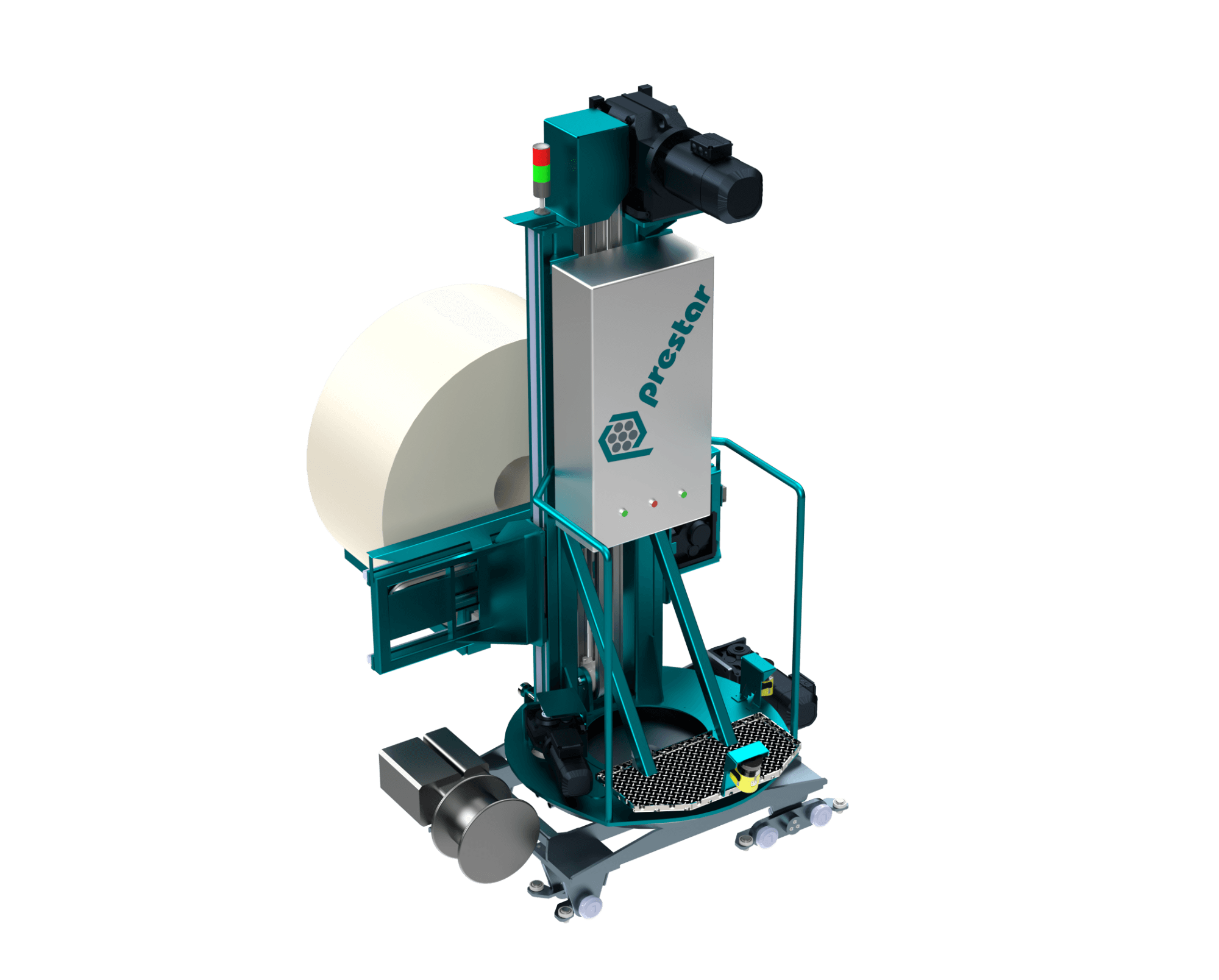

Automatic manipulator for paper rolls

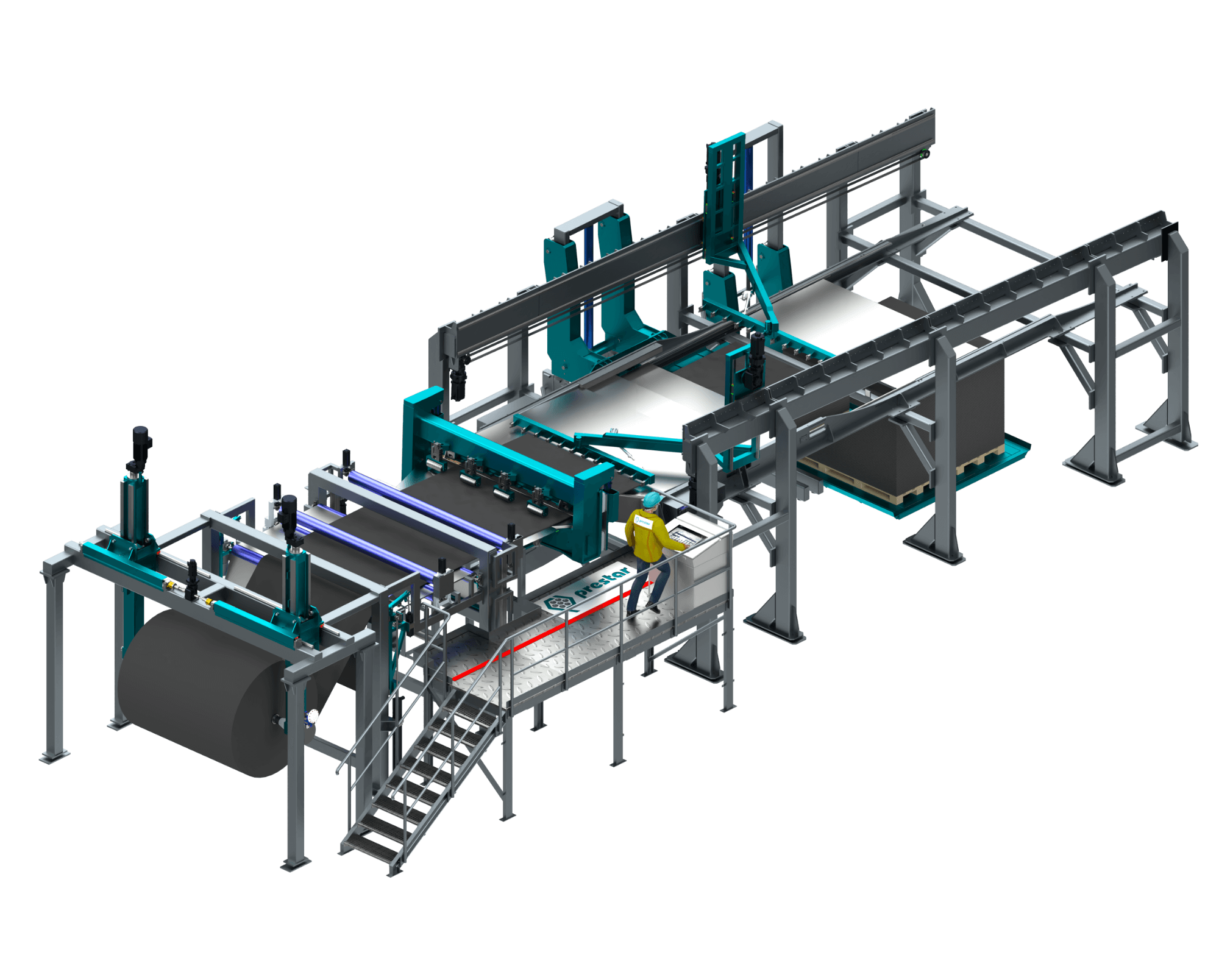

Automatic textile scissors

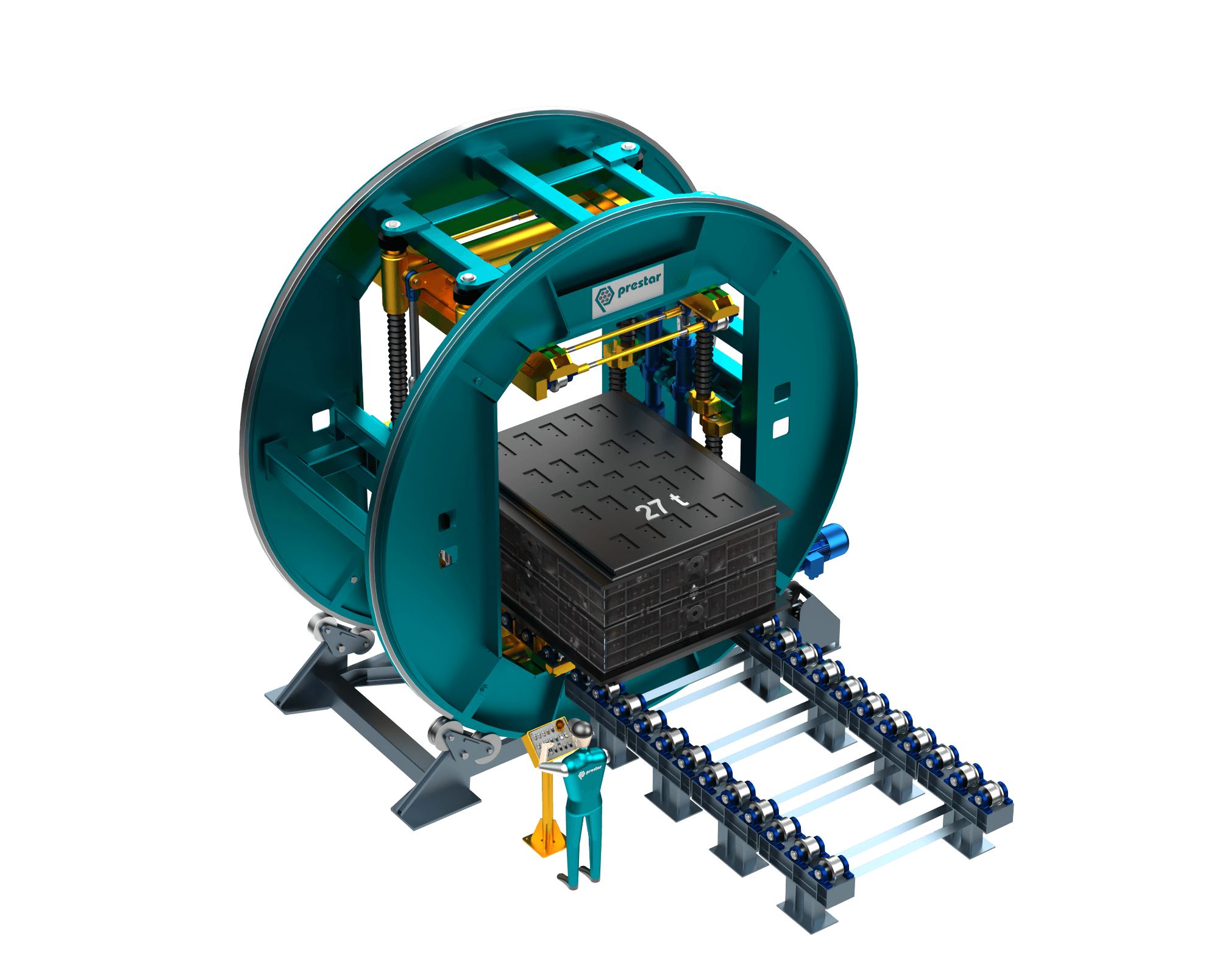

Machine for turning forms

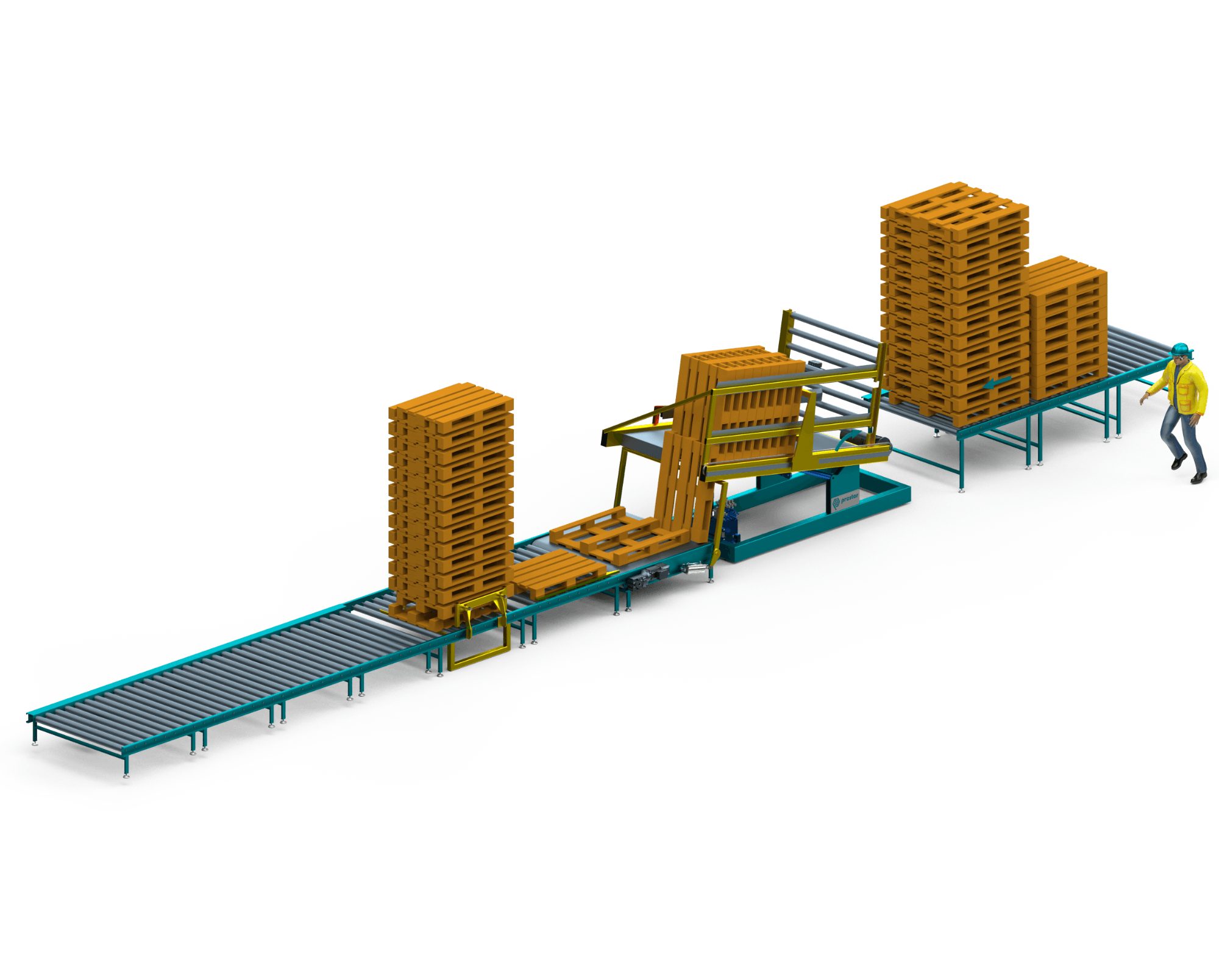

The sorting system for EUR pallets

Automation pays off