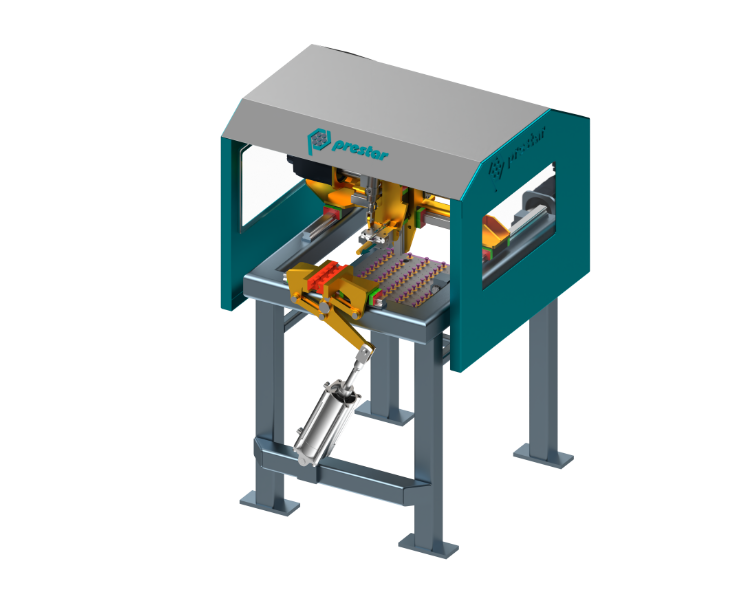

Flying saw

Description of the device

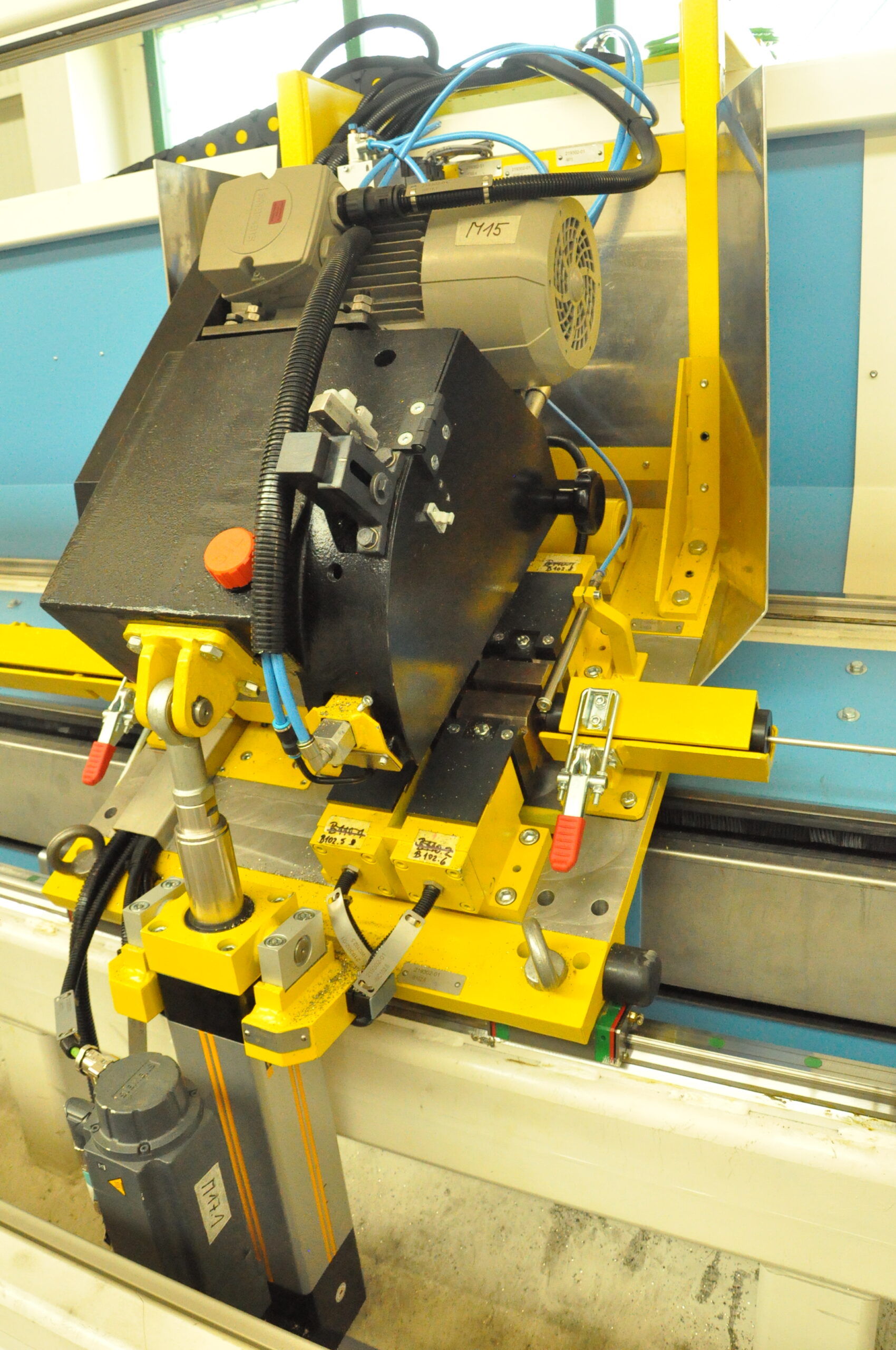

Flying saw is designed to cut pipes into precise lengths in a continuous motion called. endless pipes in a line. In the inlet, these are continuously welded pipes or pipes unwound from coils.

The flying saw is designed for tubes with a diameter of 6 – 90 mm of infinite length. The saw unit with the saw blade clamps the pipe at the saw inlet and drives the pipe at the same feed speed as the pipe feed. After a period of clamping, it cuts the pipe, releases the jaws and returns at high speed to the saw inlet.

They are always designed for a specific range of pipes according to customer requirements.

Technical parameters of the machine

|

Split diameters, profiles: |

6 – 90 mm |

|

Length after division: |

3 –21 m |

|

Feed speed of pipe, rod: |

up to 2,0 m/sec |

|

Cutting accuracy: |

+- 1,5 mm |

|

Control system: |

Simatic S7 1500T |

|

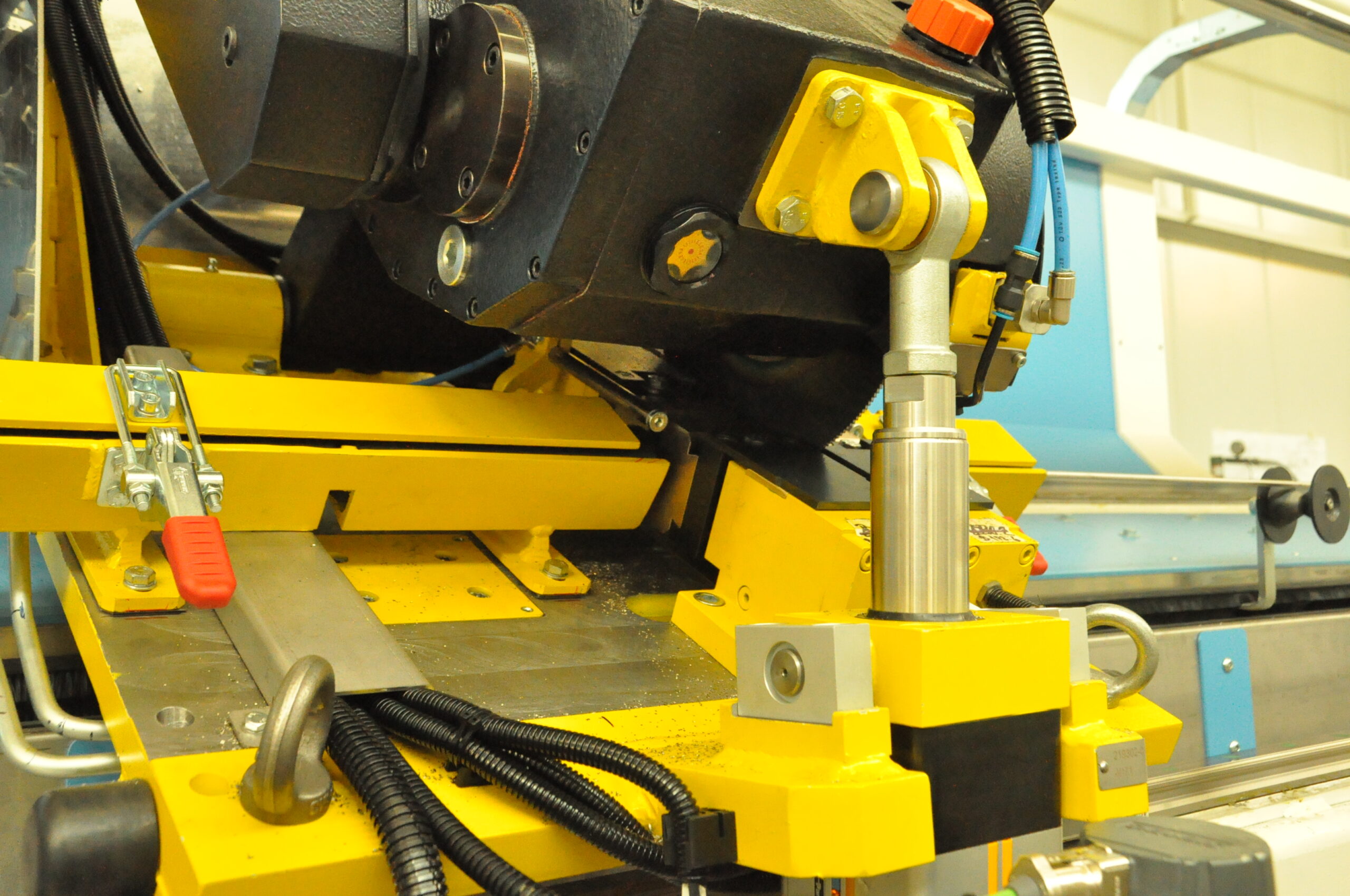

Hydraulic jaw clamping |

|

|

Feed into the section by hydraulic cylinder or servo drive |

|

|

Variable feed of the blade into the cut when cutting pipes |

|

|

Automatic lubrication system |

|

|

Safety covering with transparent glass |

|

Other equipment of the machine

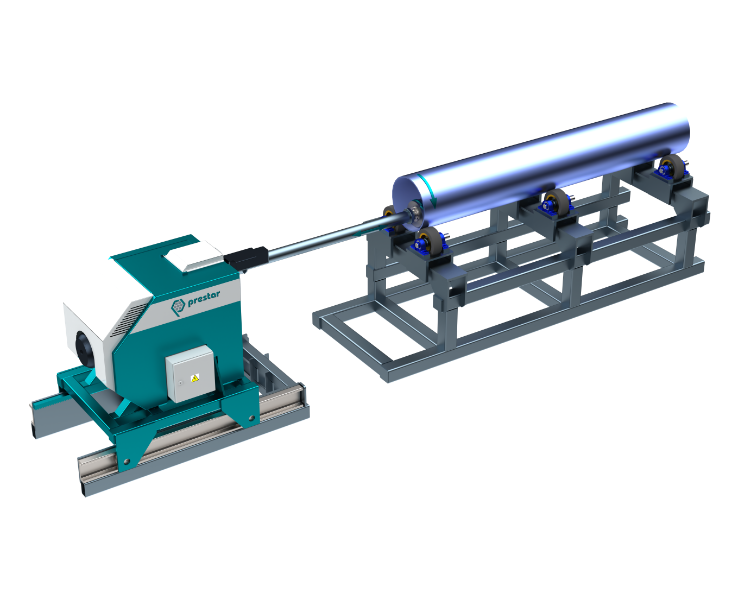

- Unwinding device before entering the flying saw with speed control.

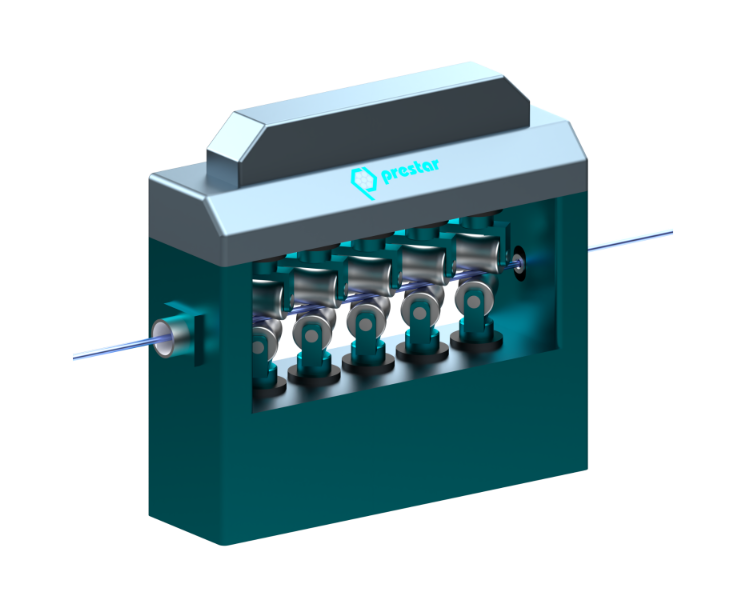

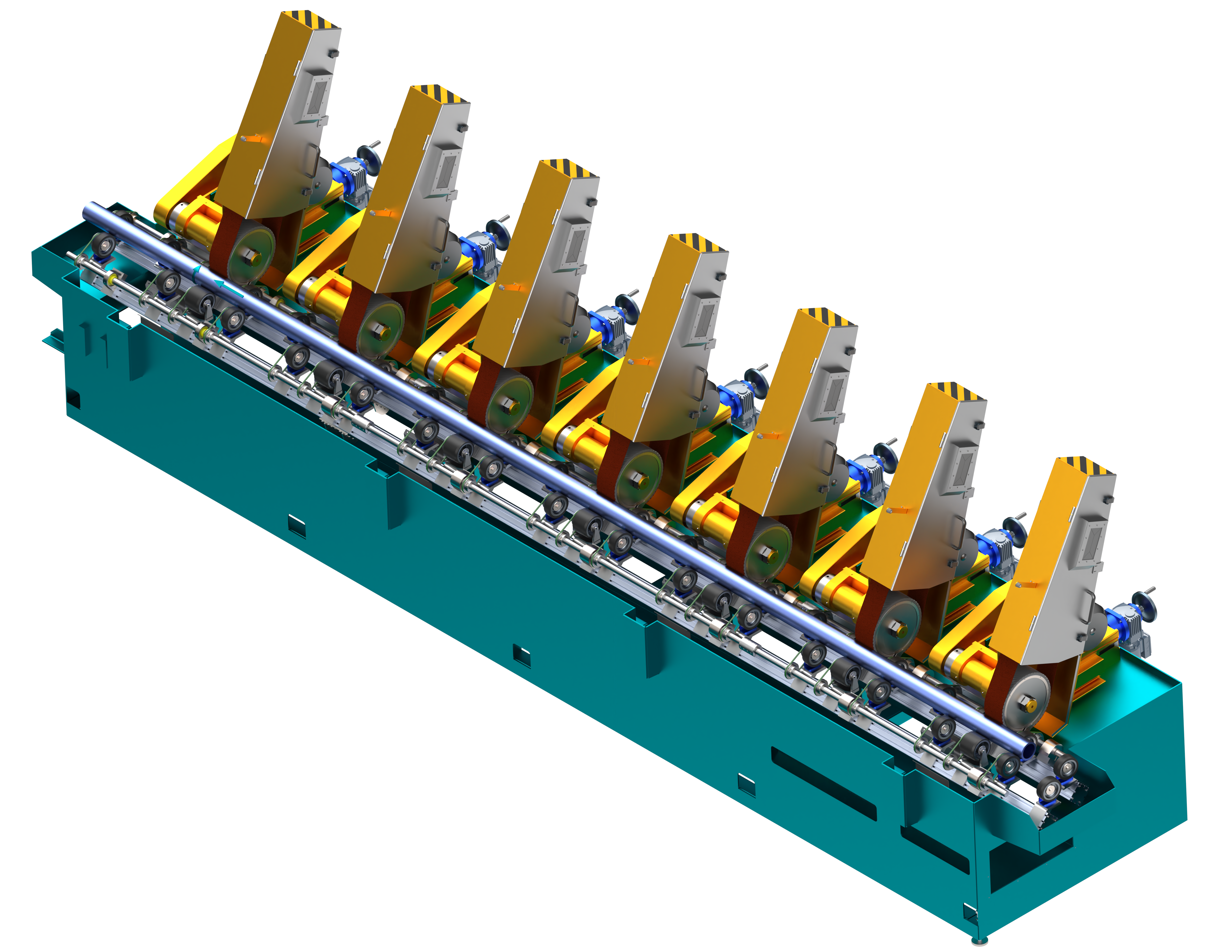

- Pre levelling of pipes and rods after unwinding before cutting on a flying saw.

- Continuous monitoring of defects and automatic carving of identified defects.

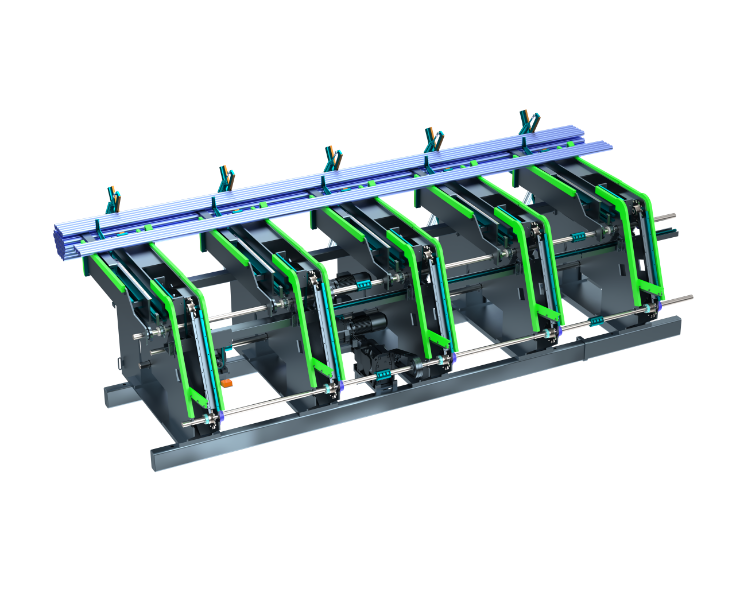

- Storage of gifted tubes and bars in pockets according to different lengths.

- Storing carved defects in a separate pocket.

- Description and marking profile

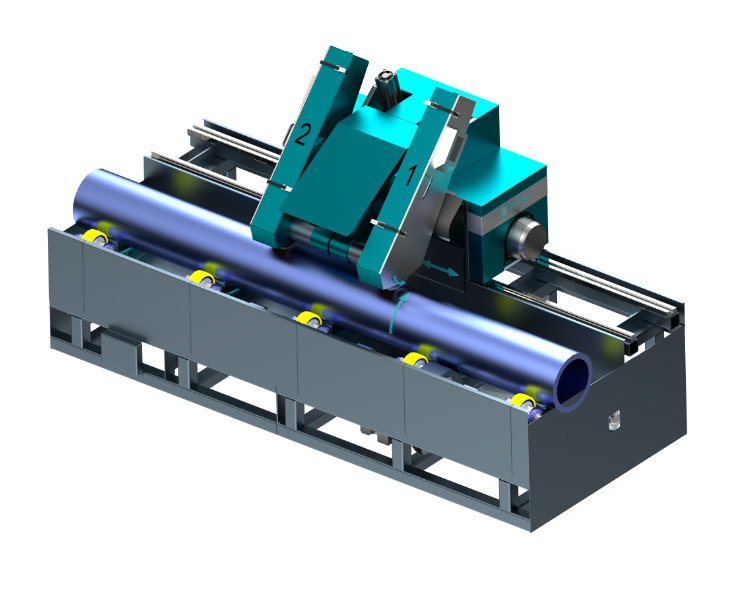

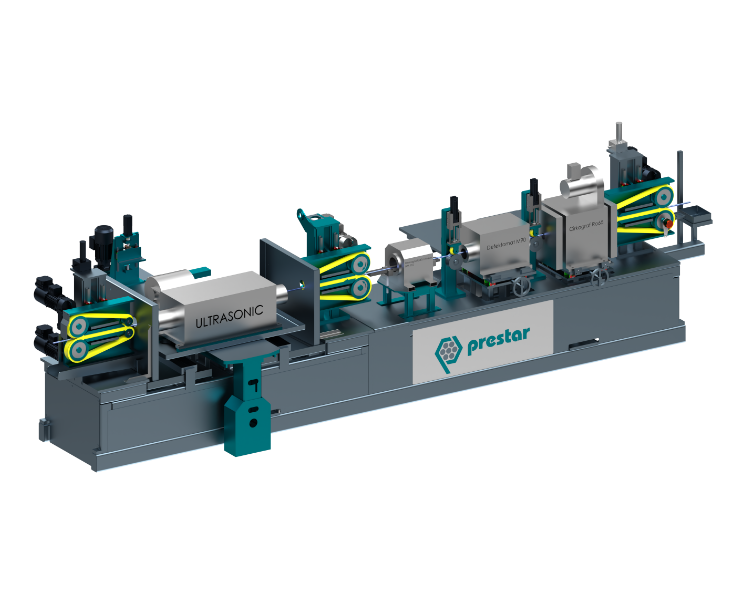

Straightening machines

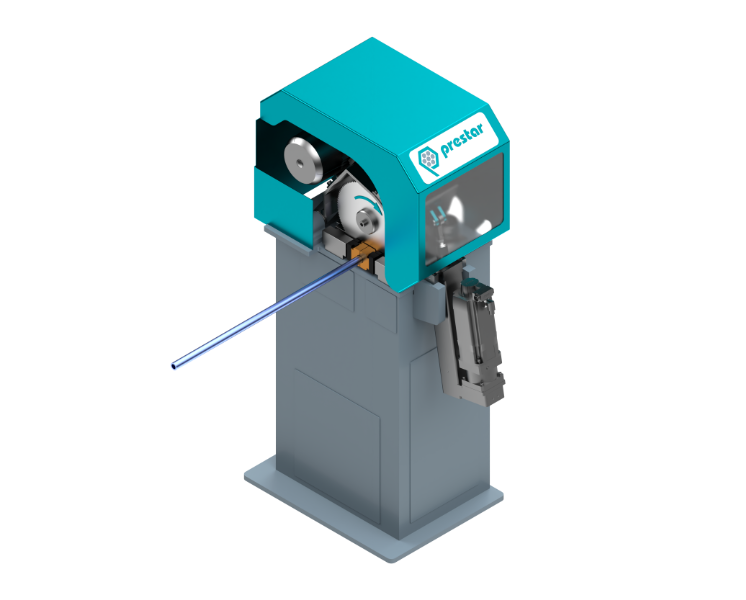

Internal pipe grinder

Centerless pipe grinder

External stationary pipe grinder

Flying saw

Circular saw

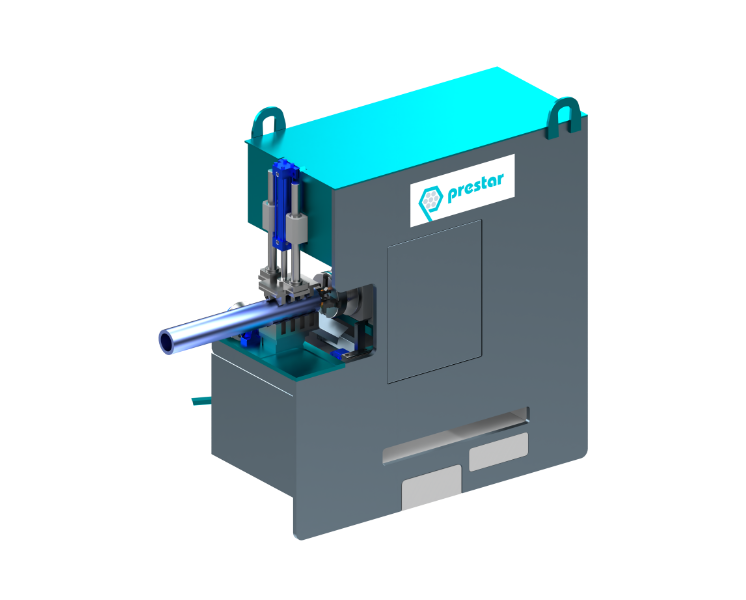

Chamfering of pipes

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT