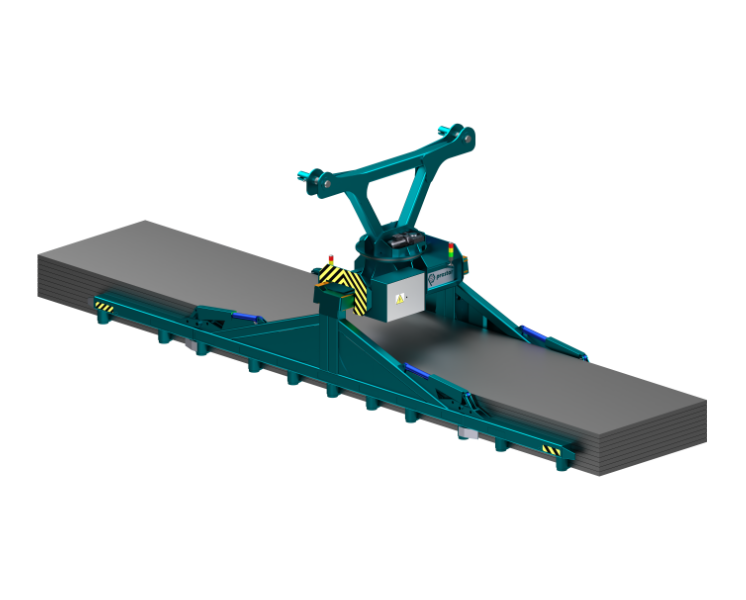

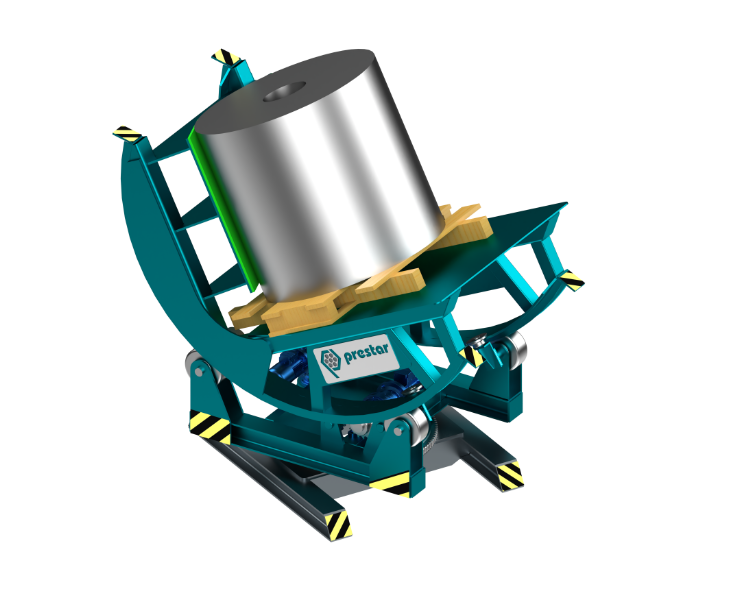

Octabine turner

Description of the device

An octabin turner is a device designed to completely and cleanly empty bulk material from octabins. The process is carried out by placing a full octabin in the station and an empty hopper trolley underneath in the raised position. Once the two are joined, the entire assembly is rotated 180° to transfer the material into the hopper car. By opening the outlet, the octabin can then be completely emptied without risk of contamination. The machine is designed for easy handling with a forklift truck.

Technical parameters of the machine

| Weight: | 2000 kg |

| Load capacity: | 1500 kg |

| Max. octabin size (WxDxH): | 1150 x 1150 x 1670 mm |

| Min. octabin dimensions (WxDxH): | 1070 x 1070 x 1080 mm |

| Turning speed: | approx. 30 s |

| Depth: | 2700 mm |

| Width: | 3100 mm |

| Height: | 3100 mm |

Other equipment of the machine

- Security fencing is used to protect the work area and ensure safe operation

Handling technology

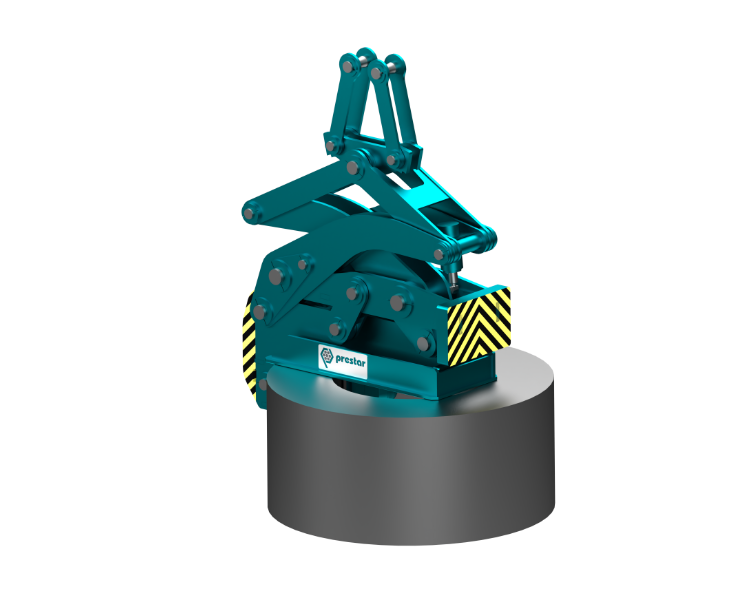

Telescopic tongs for sheet coils

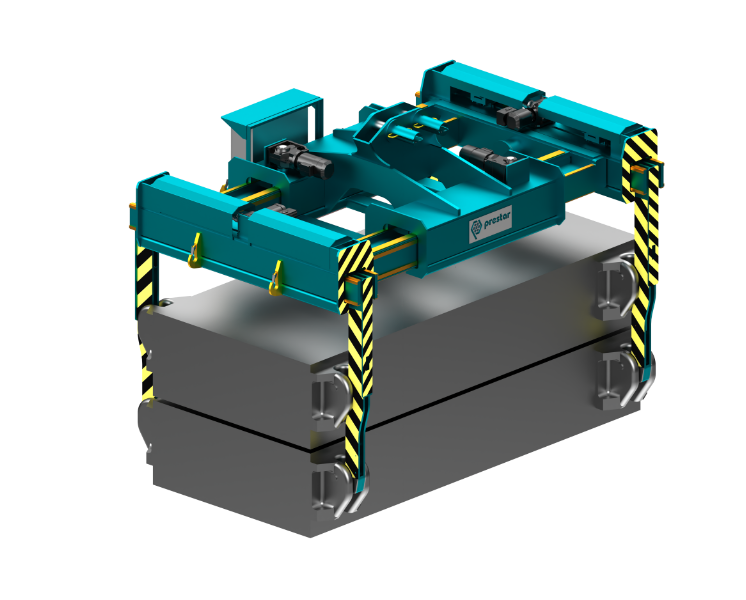

Telescopic tongs for sheet plates

Telescopic tongs for press tool

Mechanical tongs

Hydraulic tongs

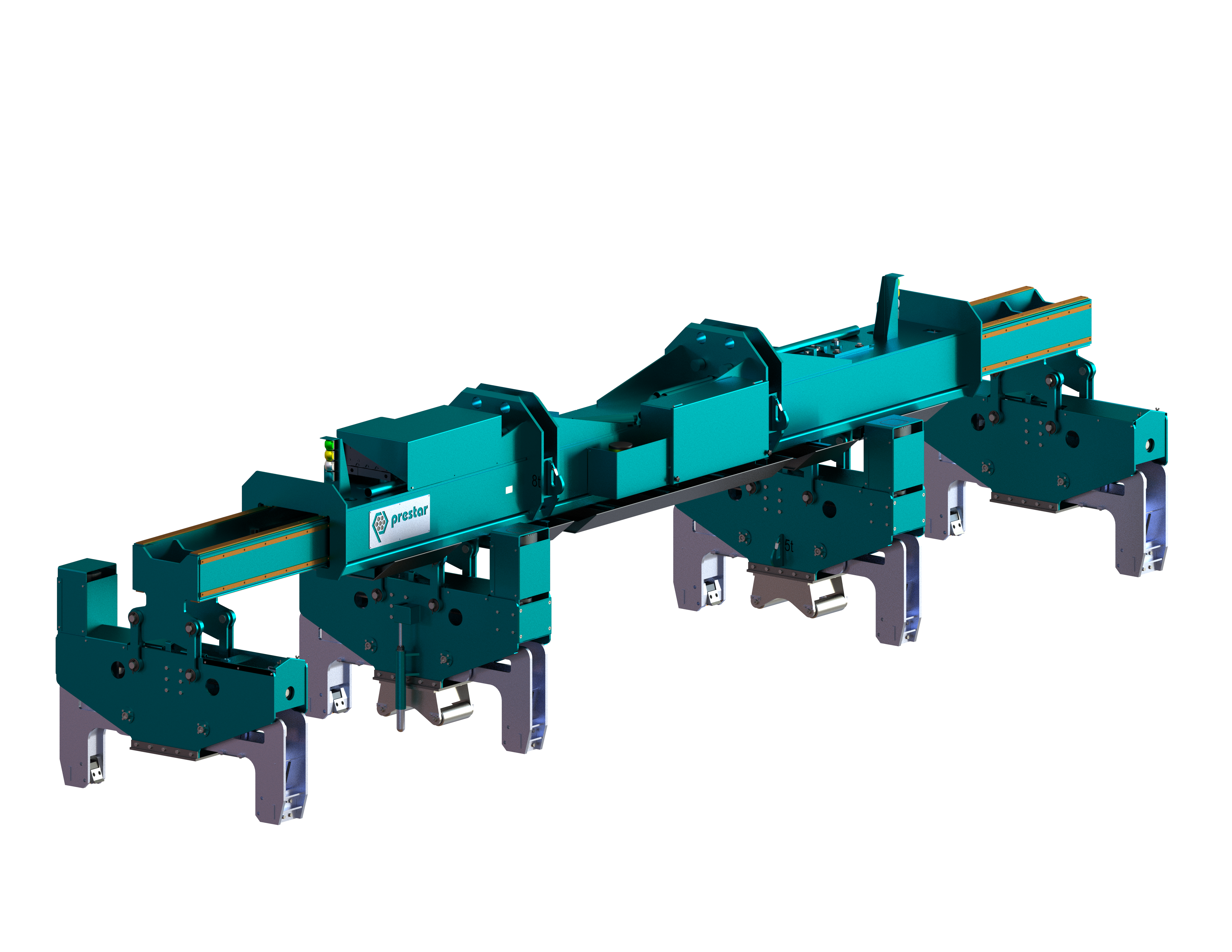

Tongs for slabs and billets

Upenders

Mould opening and folding devices

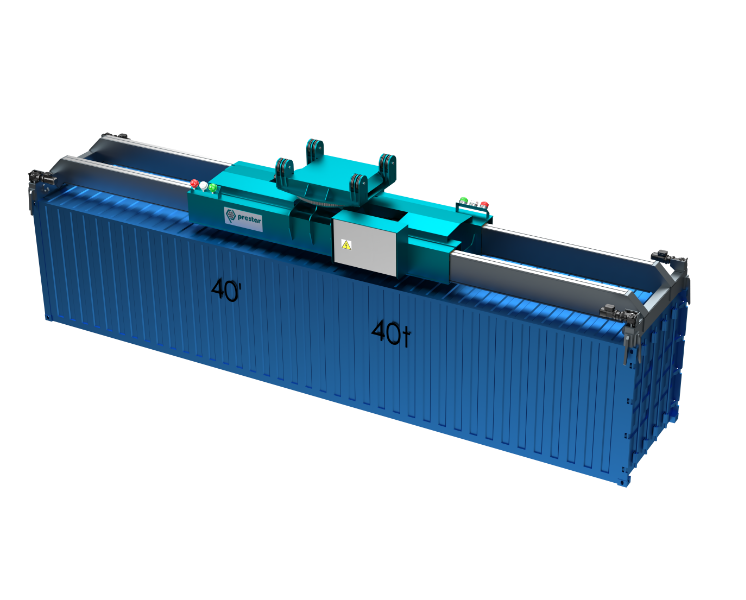

Container spreaders

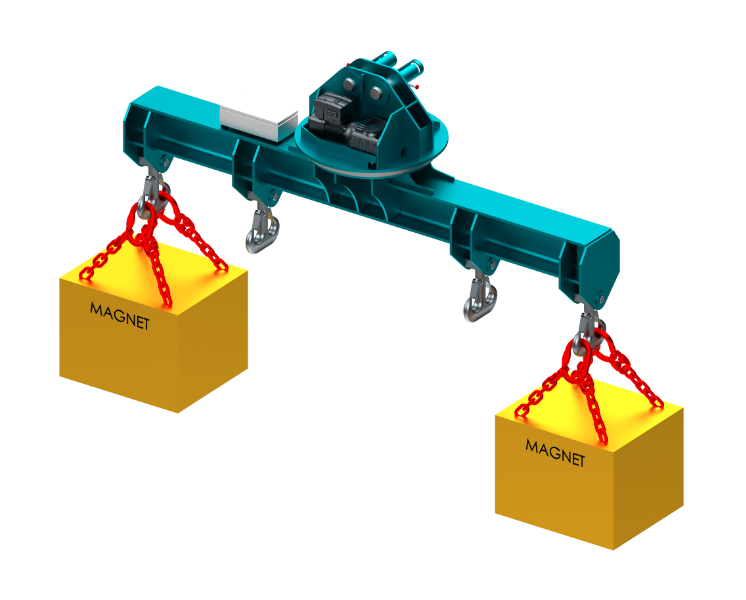

Traverses

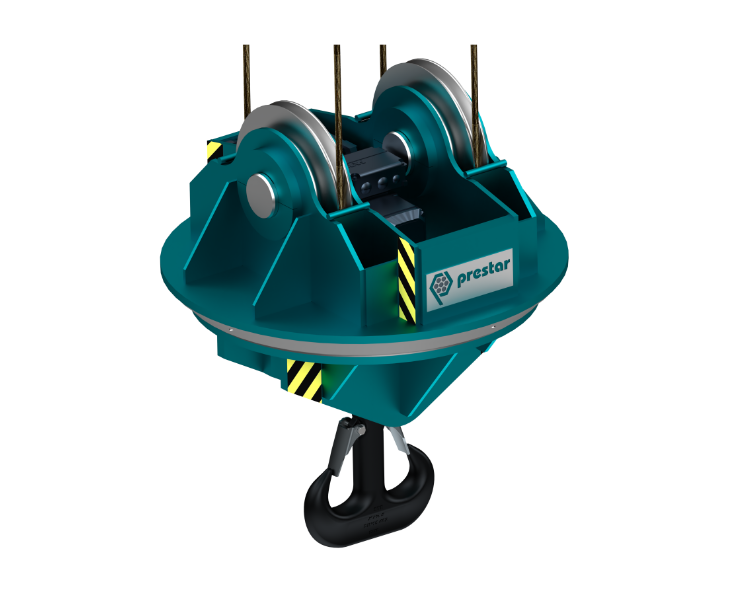

Blocks

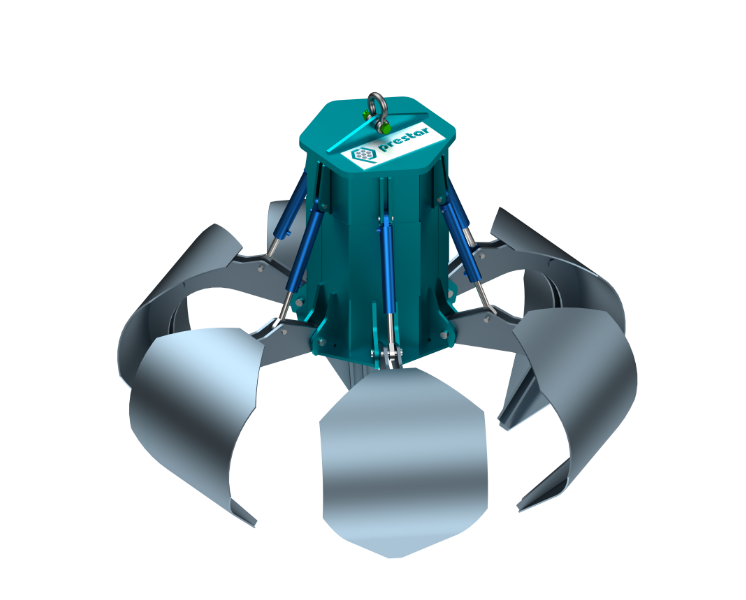

Grabs

PROPERLY SELECTED HANDLING EQUIPMENT IS BENEFICIAL