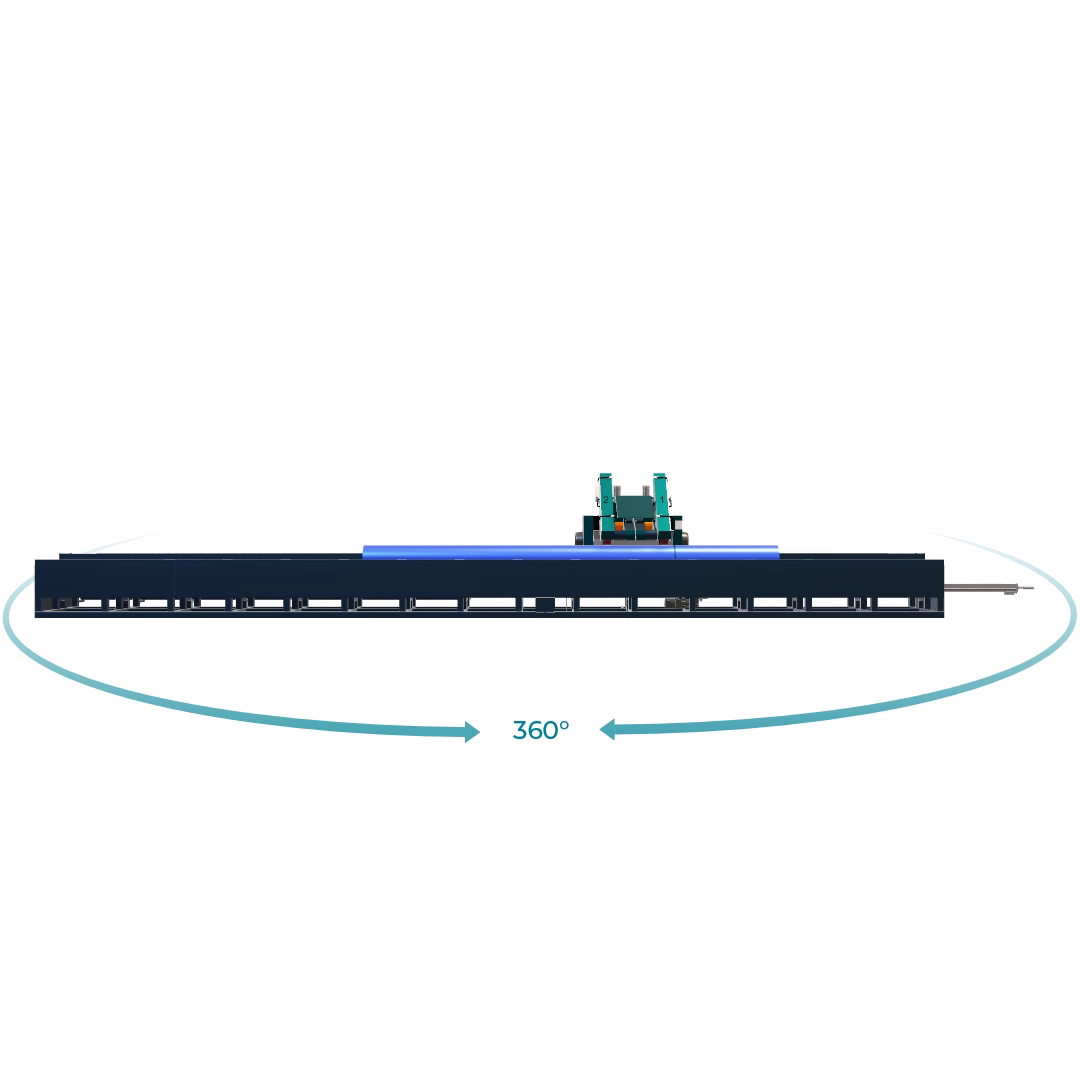

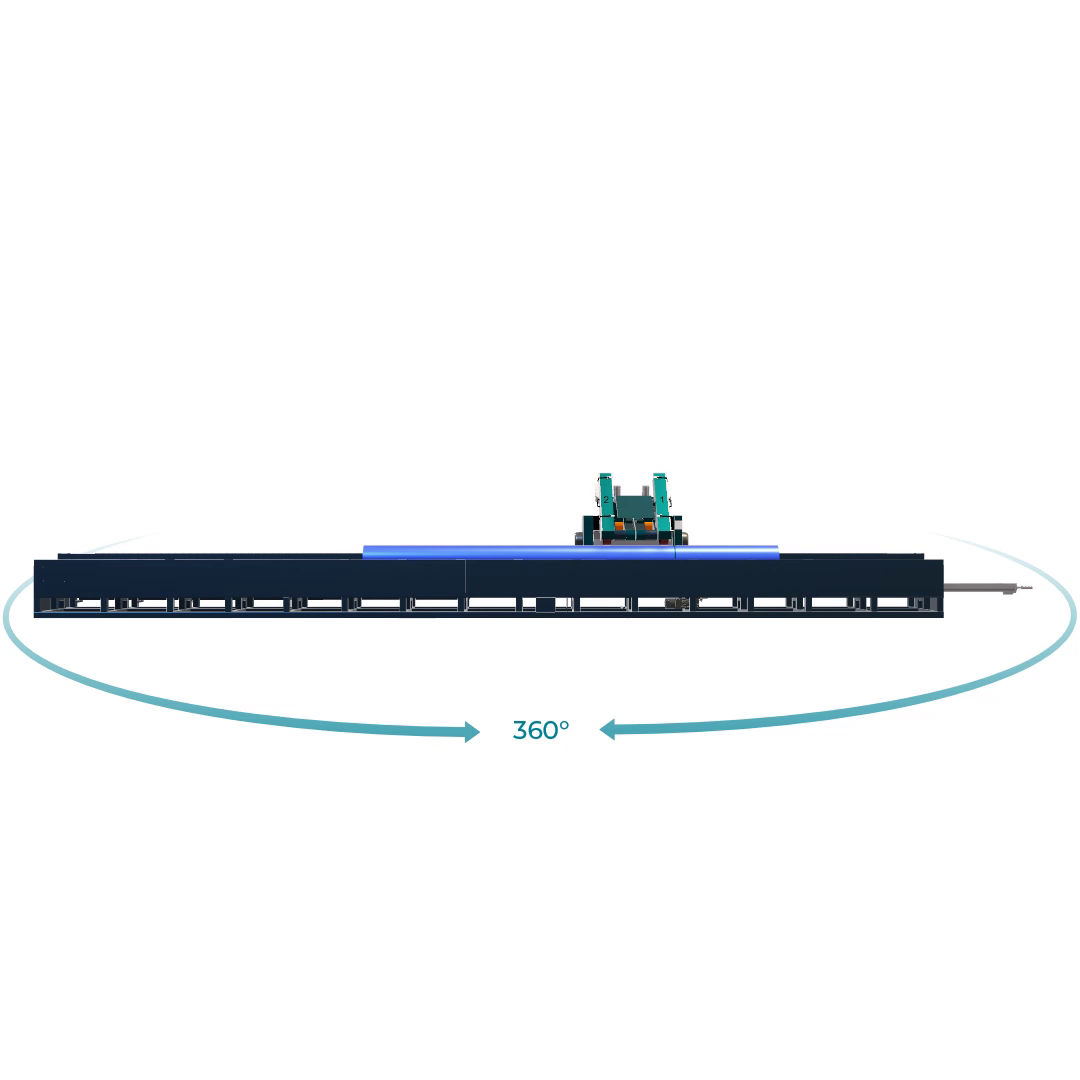

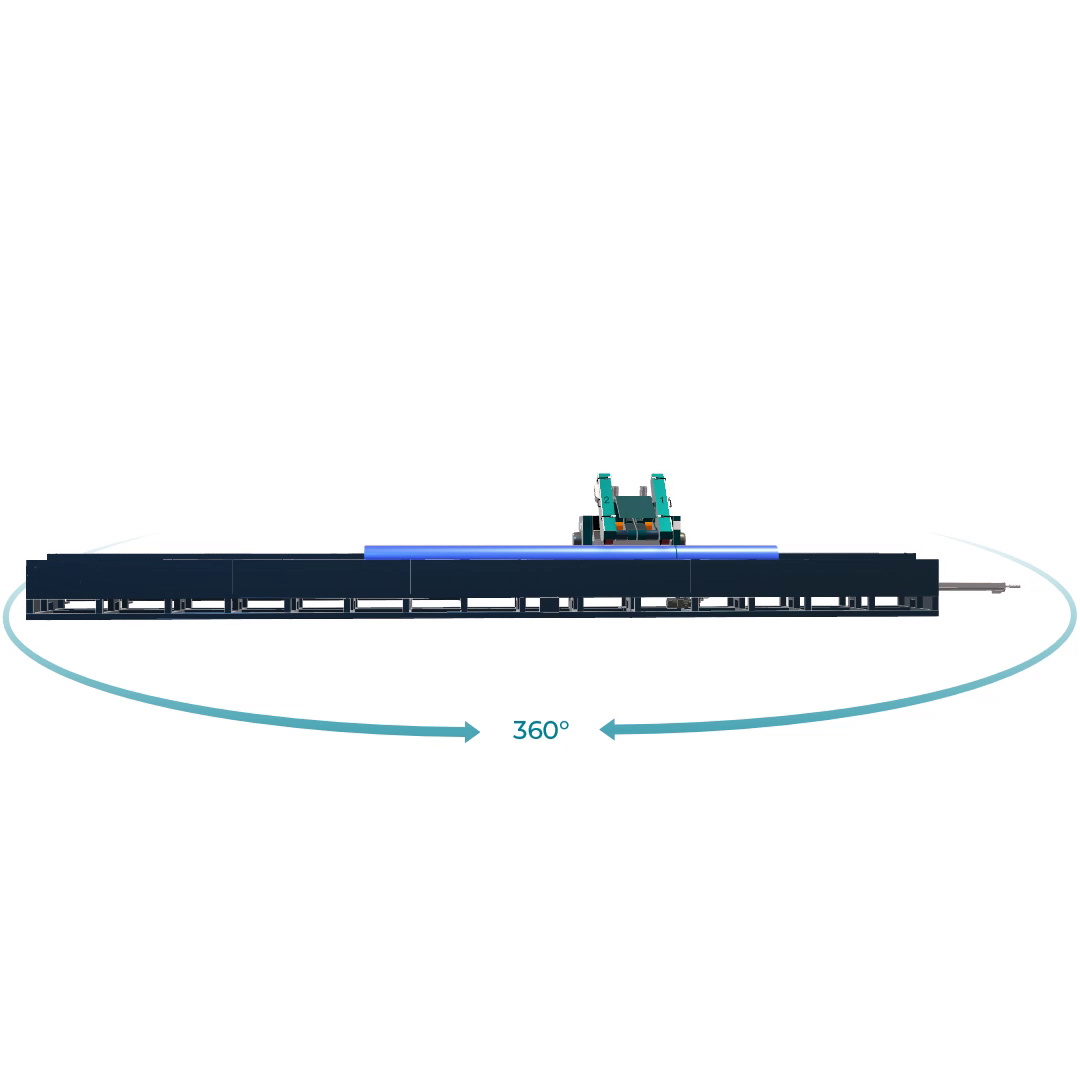

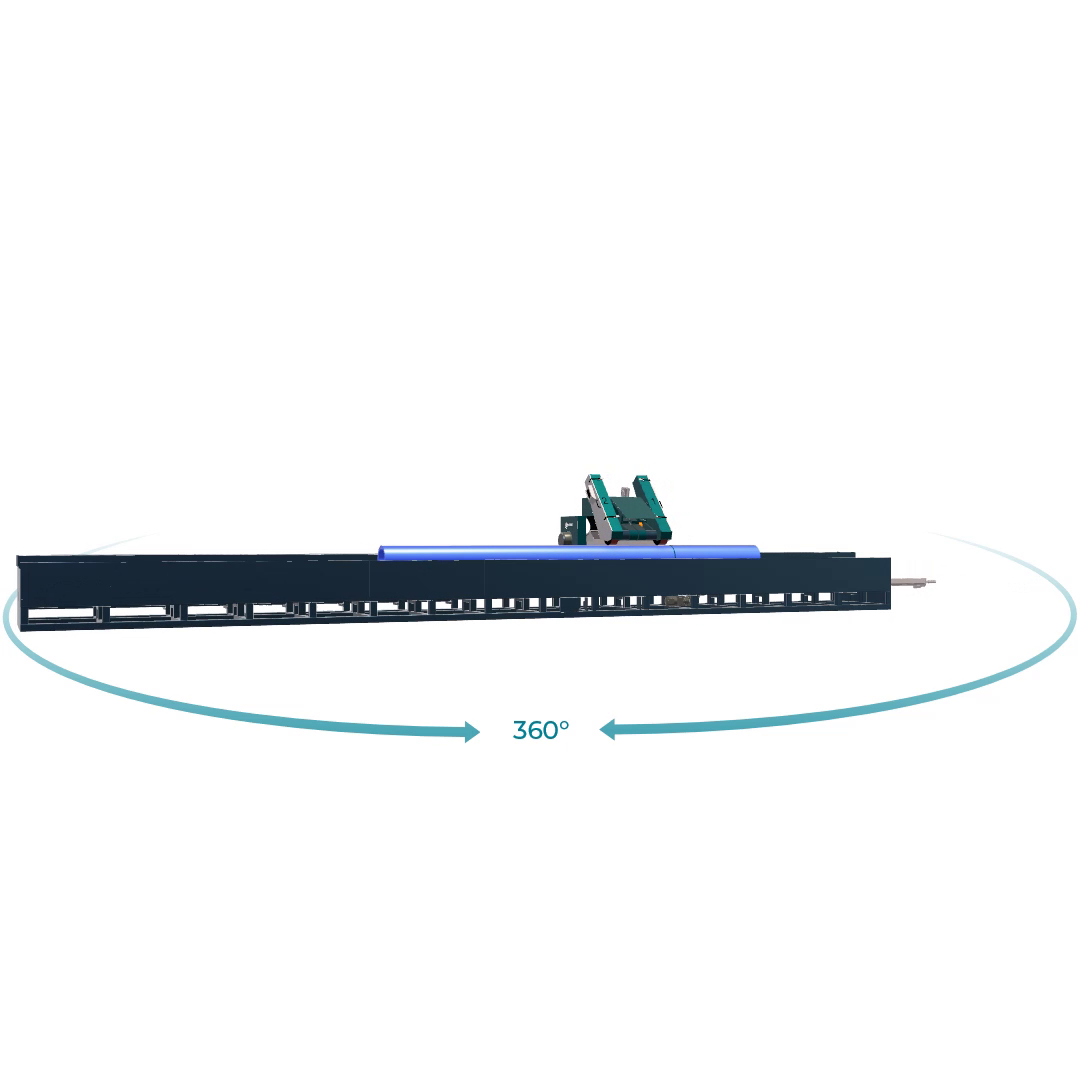

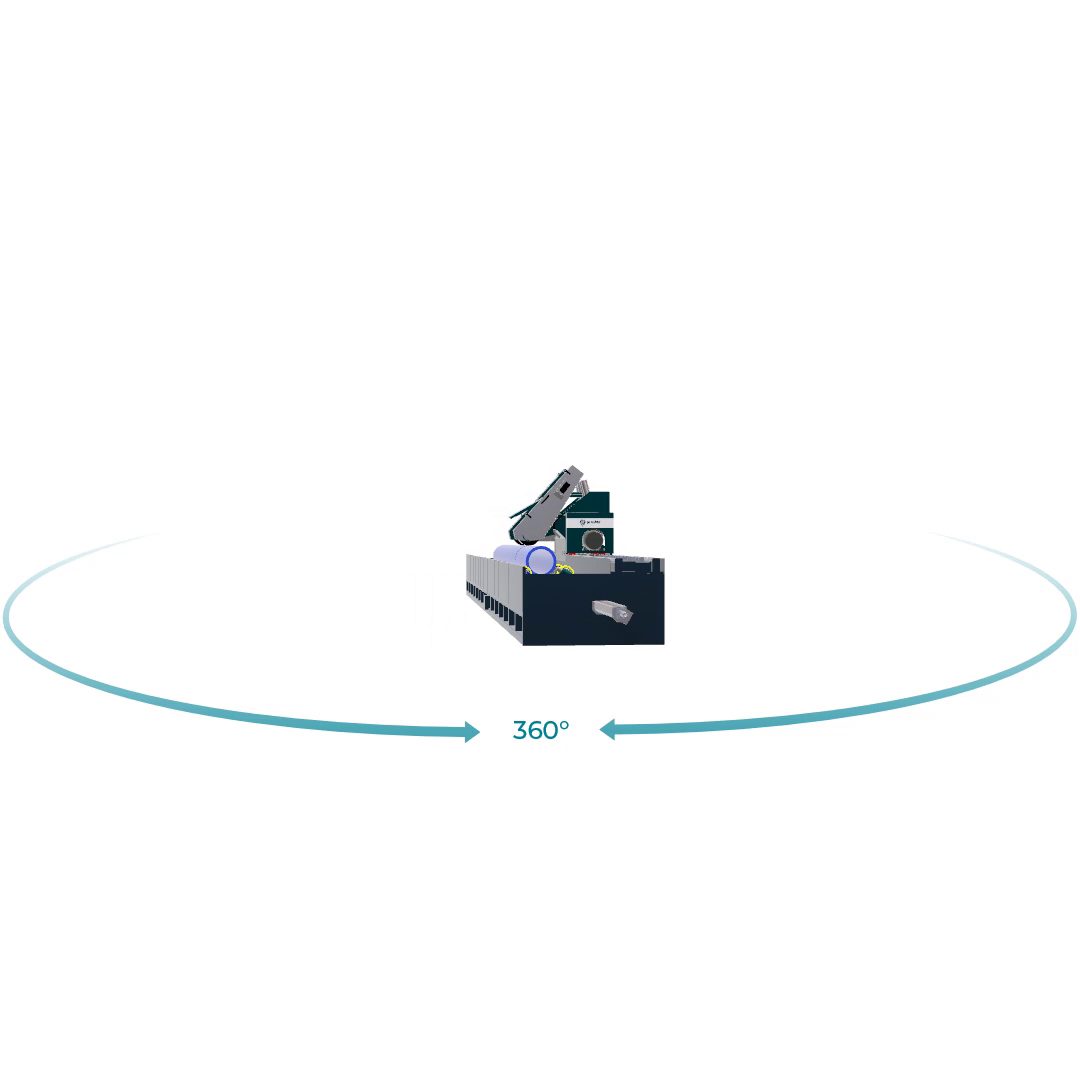

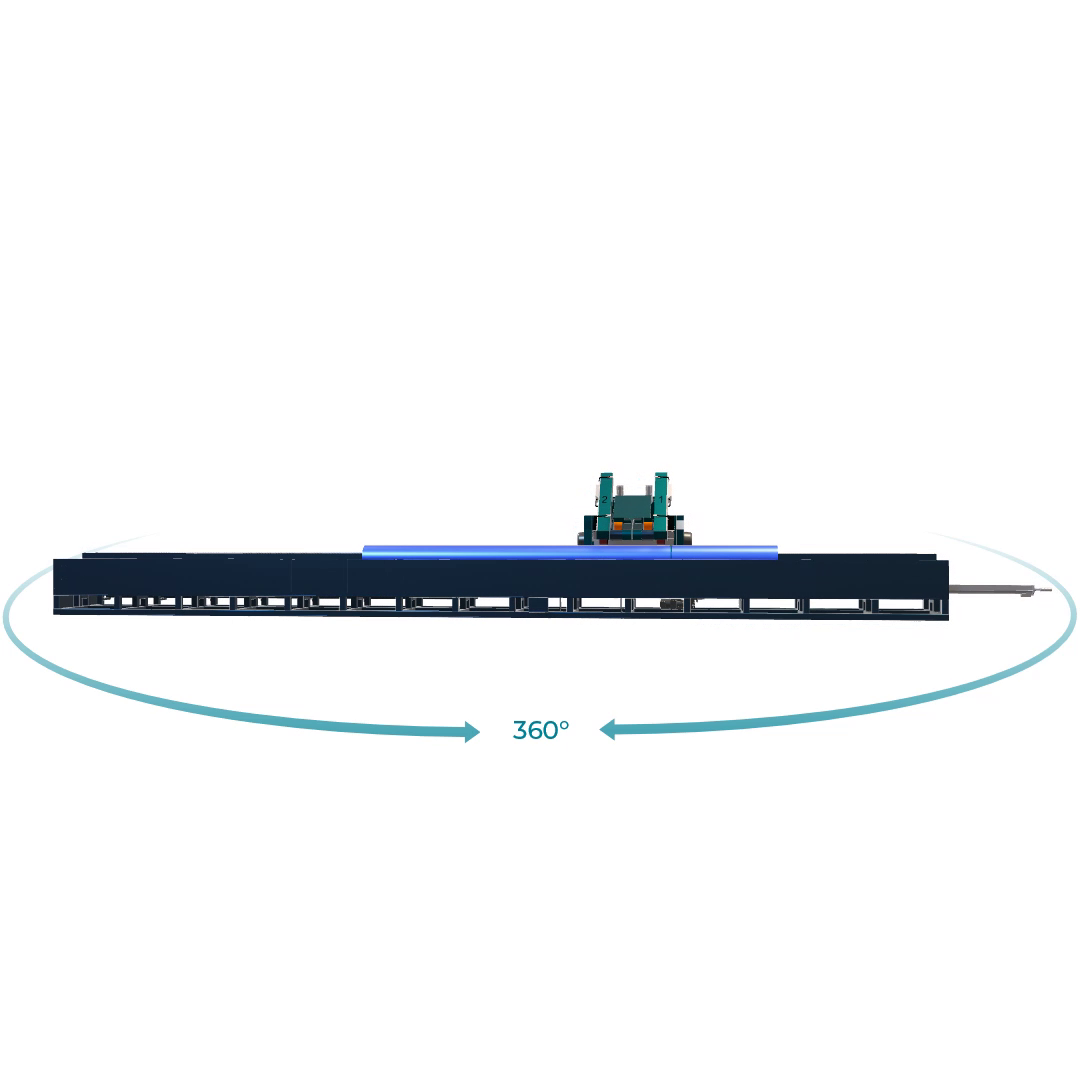

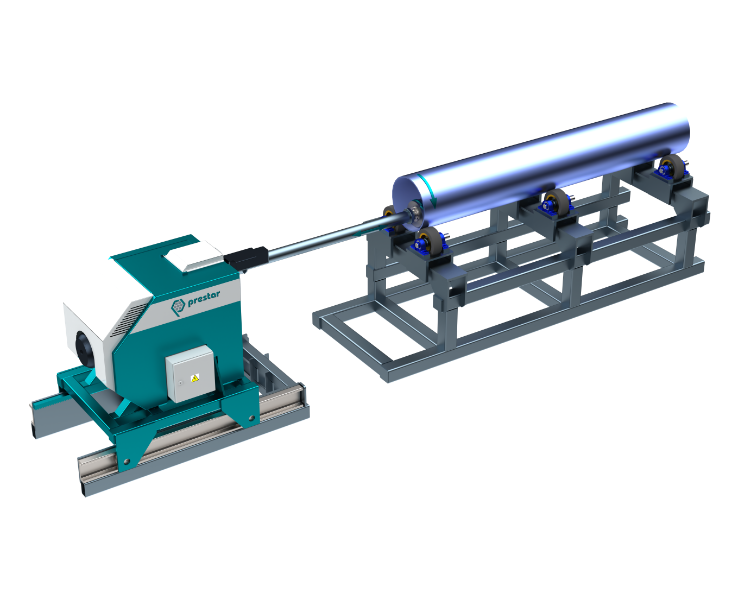

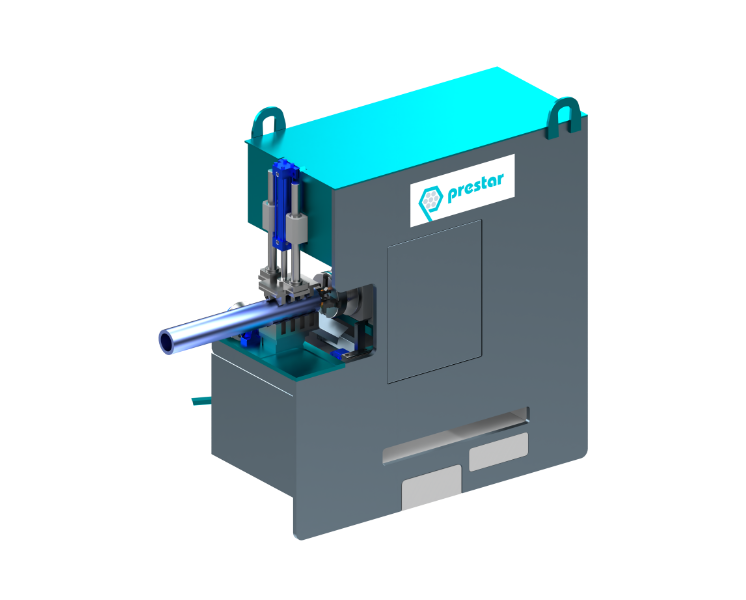

External stationary pipe grinder

Pro nejjednodušší odstranění povrchových vad

Description of the device

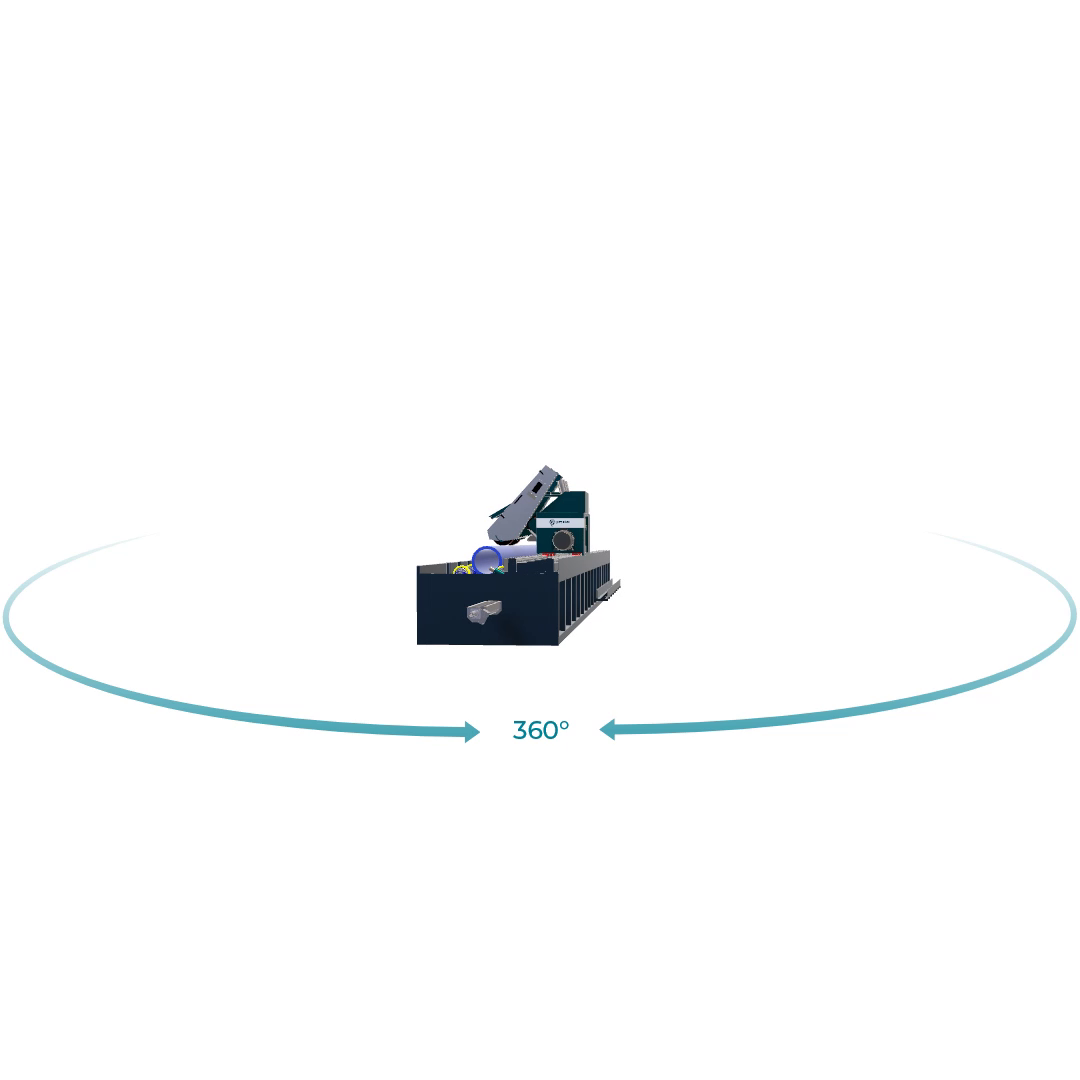

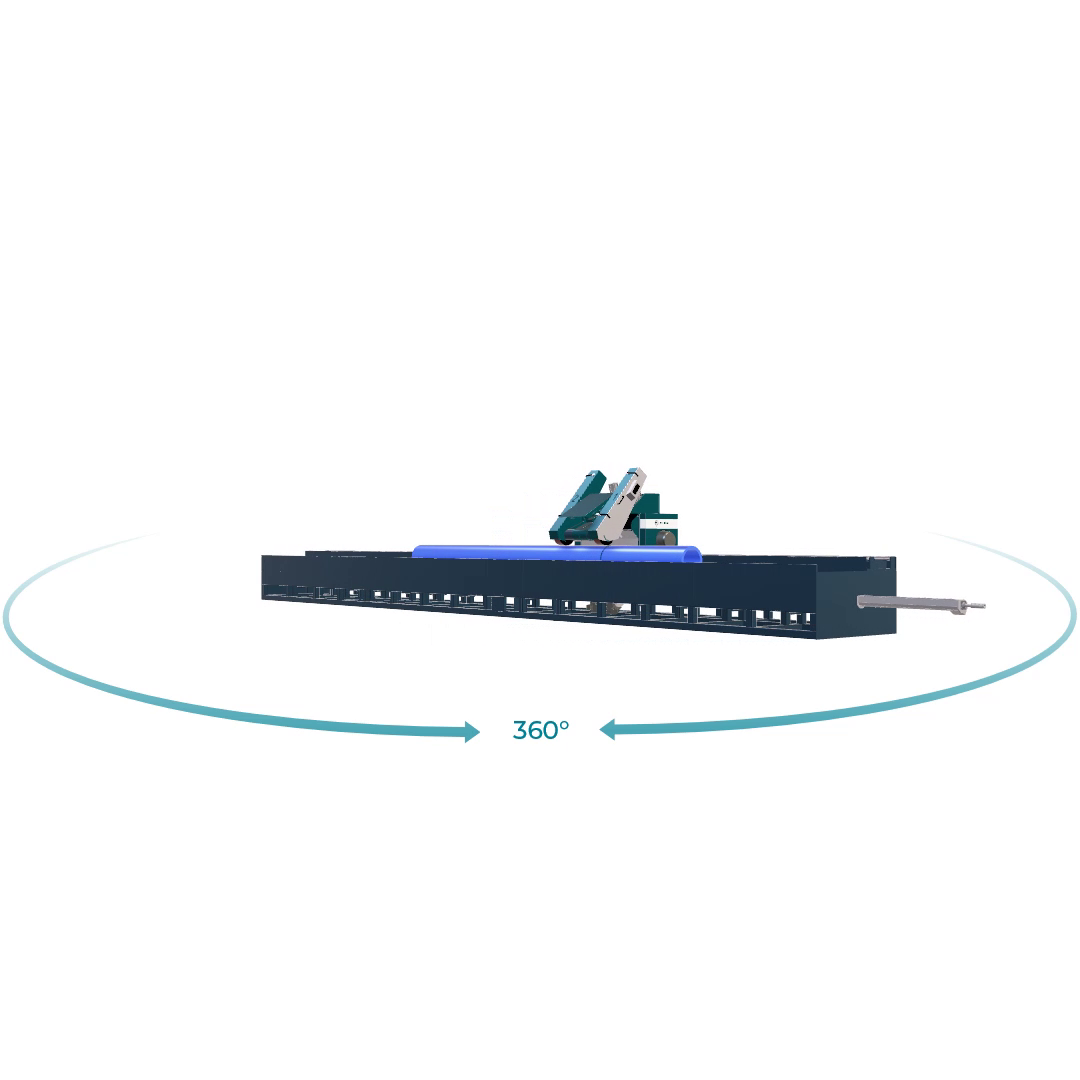

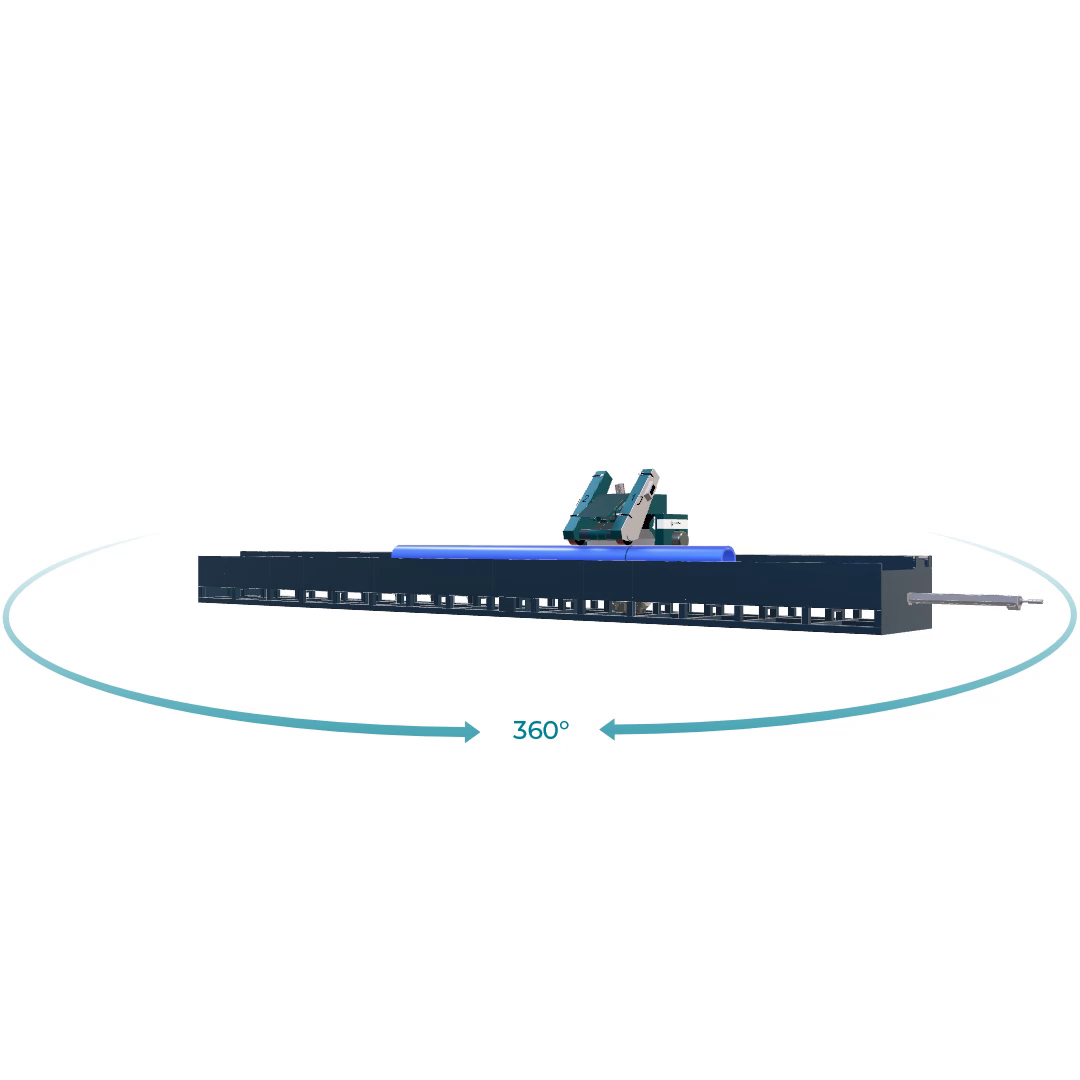

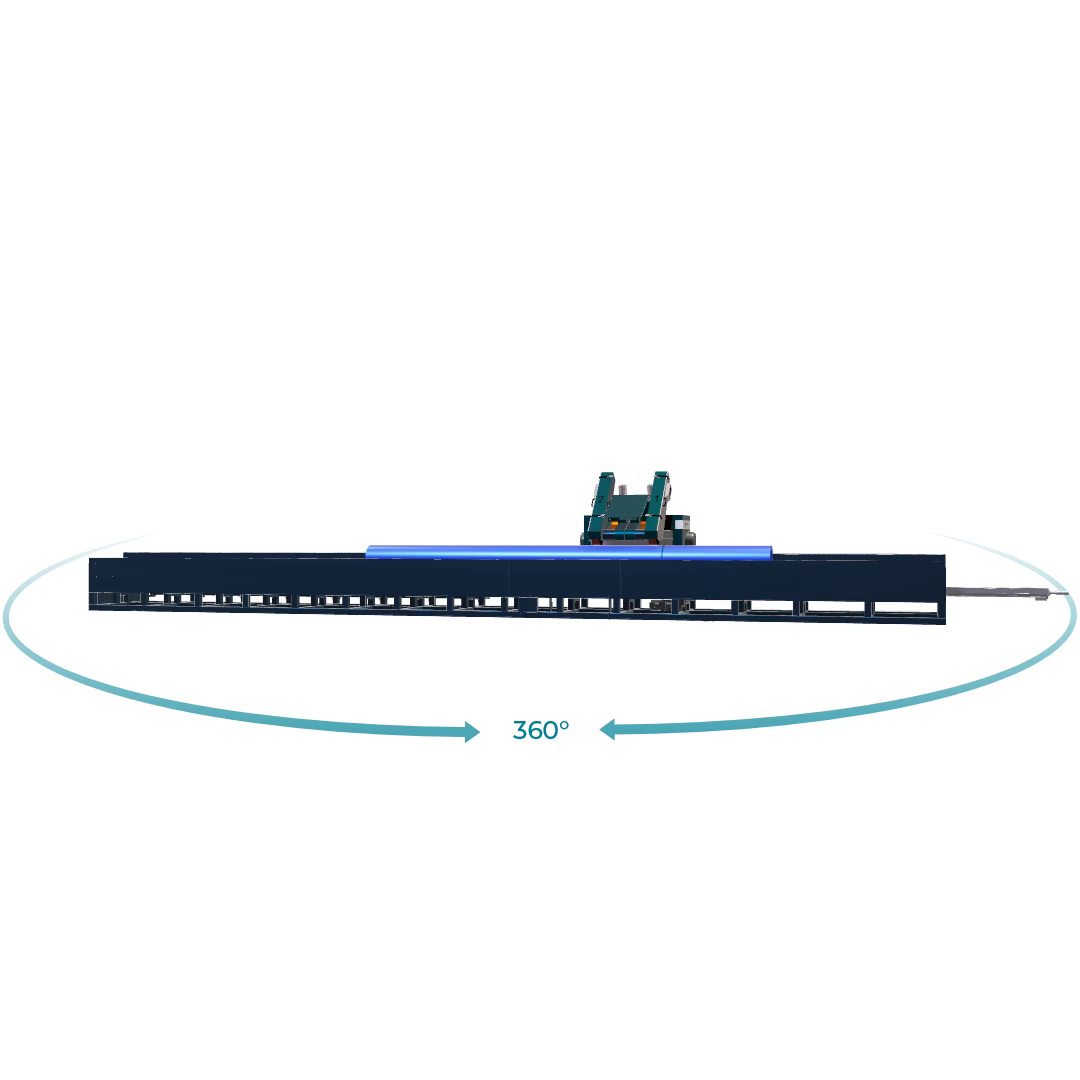

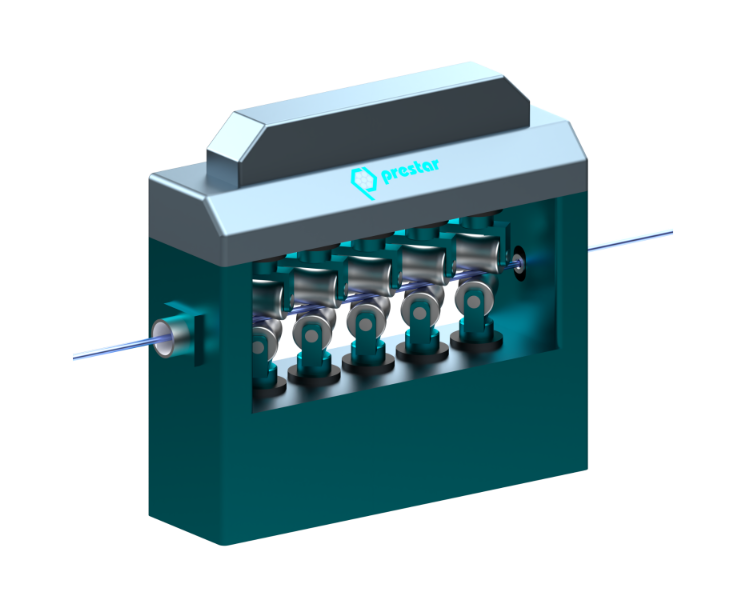

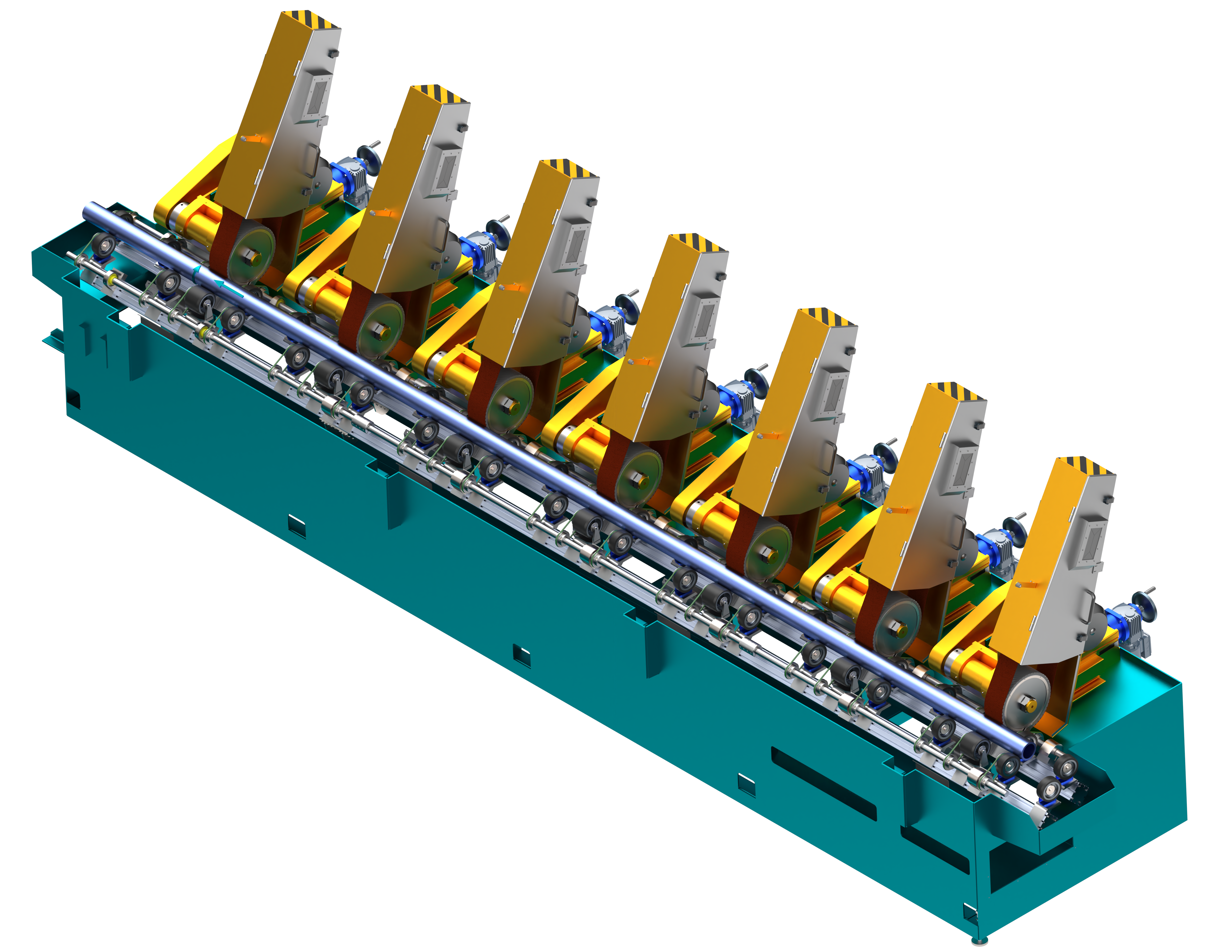

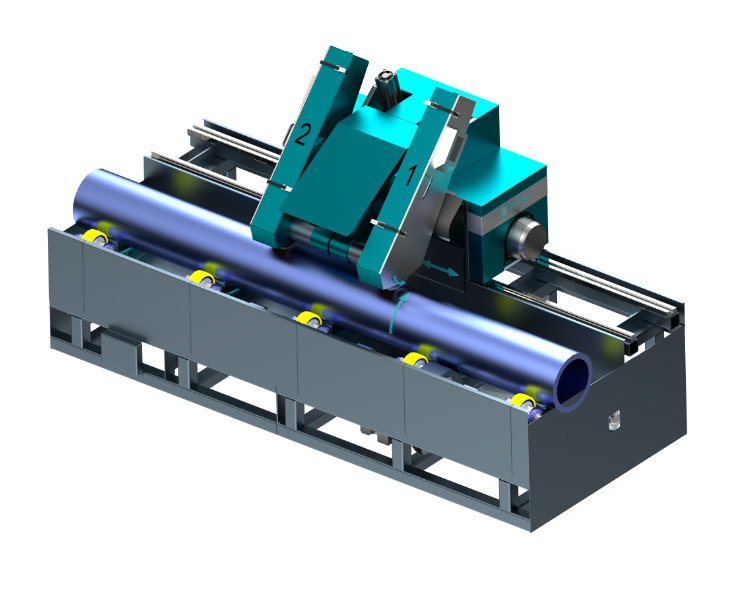

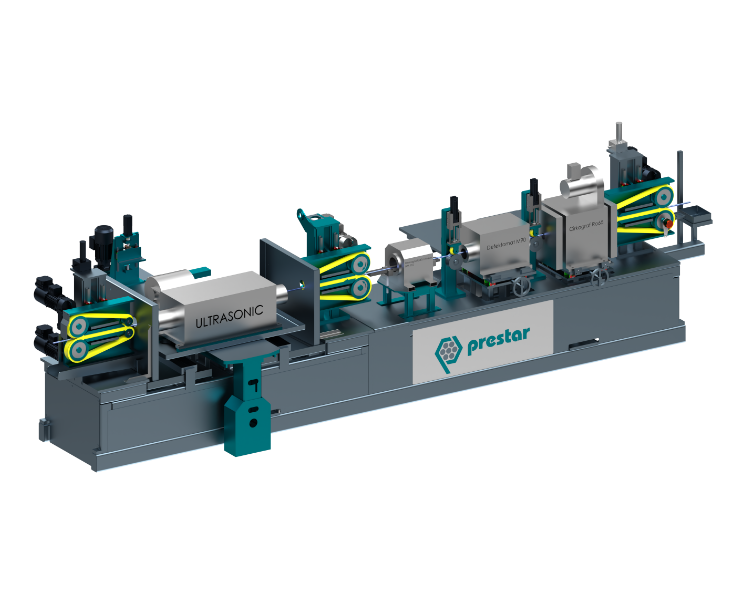

Larger diameter tubes require the outer surface to be sanded to remove scale, remove surface defects and to improve the appearance of the tubes. The pipe is loaded into the machine on driven radial rollers that are placed in a catch basin. A mobile grinding unit equipped with grinding belts is ready in the parking position next to the pipe. After start-up, the grinding unit cycles along the rotating tube and grinds the material with a constant supply of coolant. The machined material is rinsed into the tub and conveyed out of the tub by a worm shaft. Water with abraded material is filtered in three stages. Magnetic filter, fabric filter and mechanical separator. The solid residues are stored in an attached pallet and the filtered water is reused for grinding. Po broušení je trubka odebrána mostovým jeřábem.

Technical parameters of the machine

|

Pipe diameter: |

200 – 600 mm |

|

Pipe length: |

3 000 – 16 000 mm |

|

Material removal: |

up to 0,5 mm in one cycle |

|

Sanding belts: |

150 x 3 000 mm |

|

Pressure of sanding belts: |

pneumatic |

|

Sanding belt tensioning: |

pneumatic |

|

Grinding speed: |

30 m/s |

|

Sanding belt replacement: |

in the parking position of the grinding unit there is a platform for easy access to the sanding belts |

|

Control panel with display: |

placed on the mobile grinding unit |

Other equipment of the machine

- Continuous regulation of the abrasive speed of the belts.

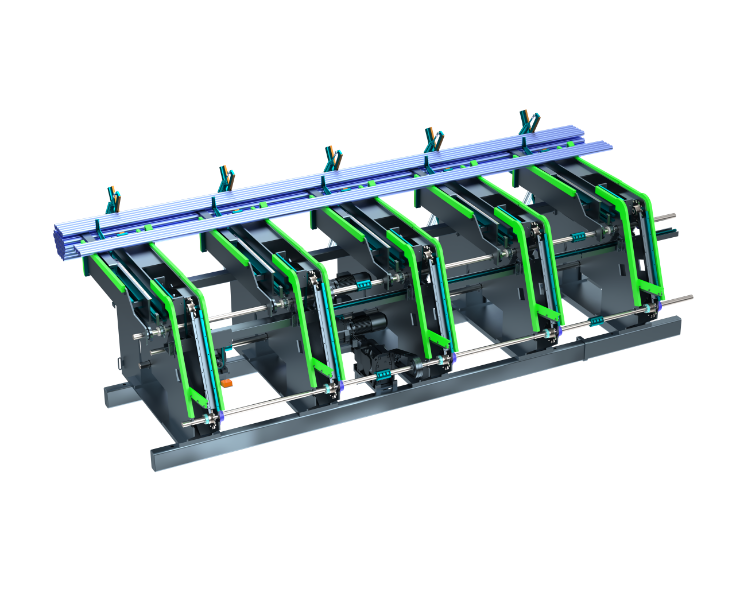

- Handling girder for inserting and removing pipes into and out of the machine.

- Manual ultrasound tube wall thickness measurement.

- Extended visualization with an emphasis on intuitive and detailed display of operating states and the place of failure of the grinder.

- Extended service with the possibility of displaying manuals, service manuals and other necessary documentation on machines to minimize service times.

- Collection of agreed production parameters with automatic saving, display and data export.

Rovnací stroje

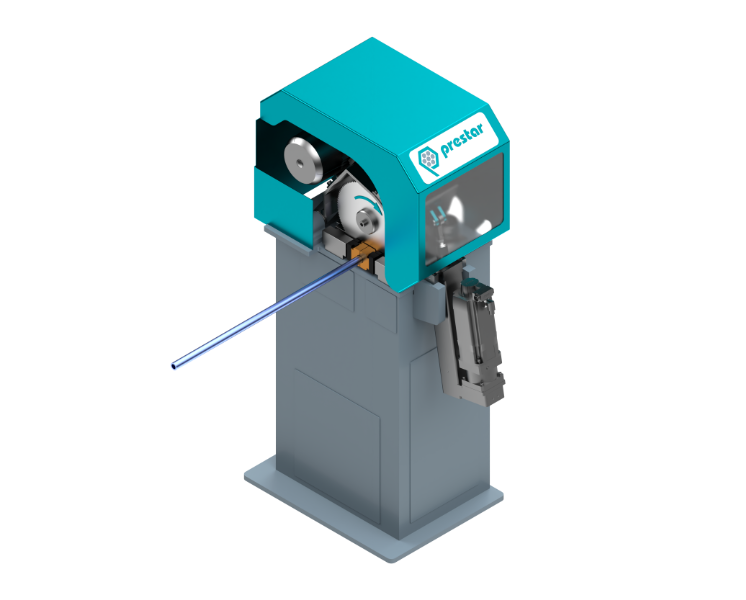

Bruska trubek vnitřní

Bruska trubek vnější Centerless

Bruska trubek vnější Stacionární

Letmá pila

Kotoučová pila

Úkosování trubek

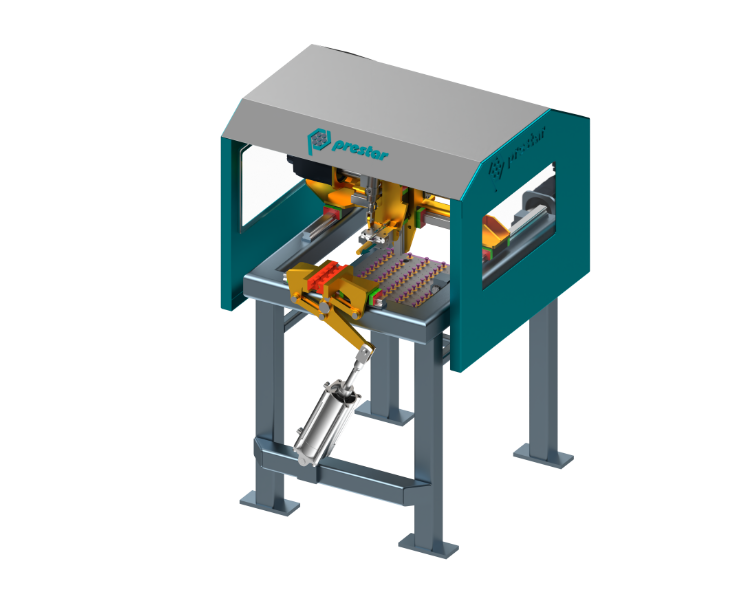

Třídění a zátkování

Kontrolní stoly

Balící stroje

Nová linka na trubky nebo tyče prokazatelně zefektivní výrobu

90% zákazníků vnímá technologie firmy Prestar jako vysoce pokrokové

Naše řešení v průmyslu:

Kartáčování (odjehlování) konců trubek – bezpečný a přesný způsob od Prestar s.r.o.

Při dělení nebo obrábění trubek často vznikají ostré hrany, otřepy a drobné jehličky. Tyto nerovnosti mohou ohrozit bezpečnost, zkomplikovat montáž a negativně ovlivnit kvalitu spoje....

Zařízení pro utěsnění konců trubek před ultrazvukovou zkouškou

Automatické zátkovací/odzátkovací stanice – bezpečné a přesné těsnění trubek Pro zajištění přesnosti a spolehlivosti při nedestruktivním testování trubek (NDT), zejména ultrazvukových zkouškách, je...

Stacionární bruska na trubky – přesné broušení vnějšího povrchu ocelových trubek

Proč používat stacionární brusku na trubky? Broušení vnějšího povrchu ocelových trubek větších průměrů je zásadní pro dosažení požadované kvality, bezpečnosti a výsledného vzhledu. Naše stacionární...